OLED luminous layer structure capable of avoiding color cast and coupled film of OLED luminous layer structure

A technology of light-emitting layer and coupling film, applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve problems such as uneven distribution, loss of light intensity, color shift of mobile phone screens, etc., to improve optical quality, eliminate color cast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

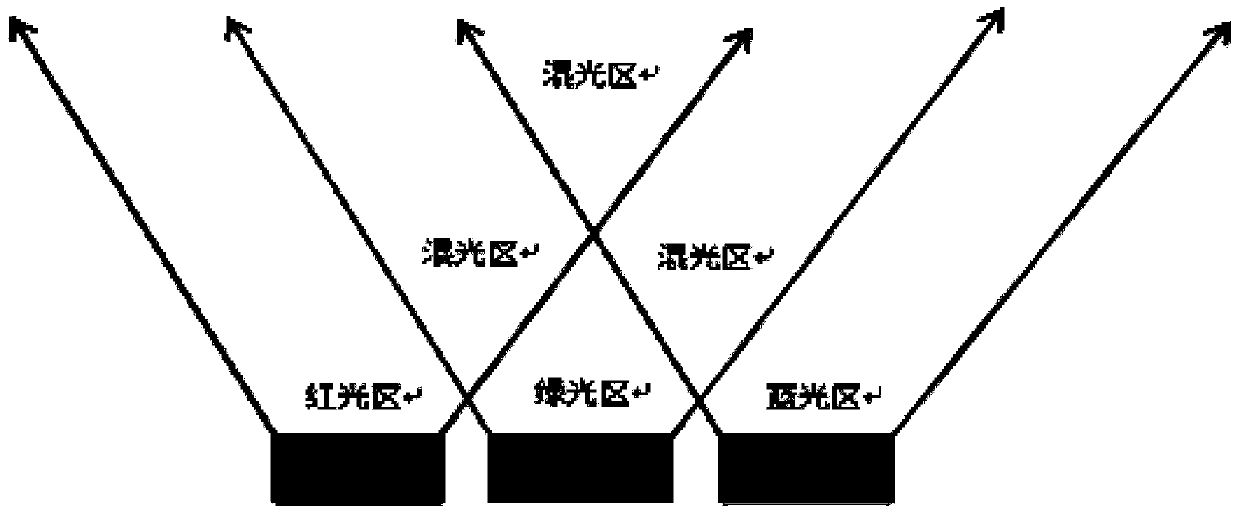

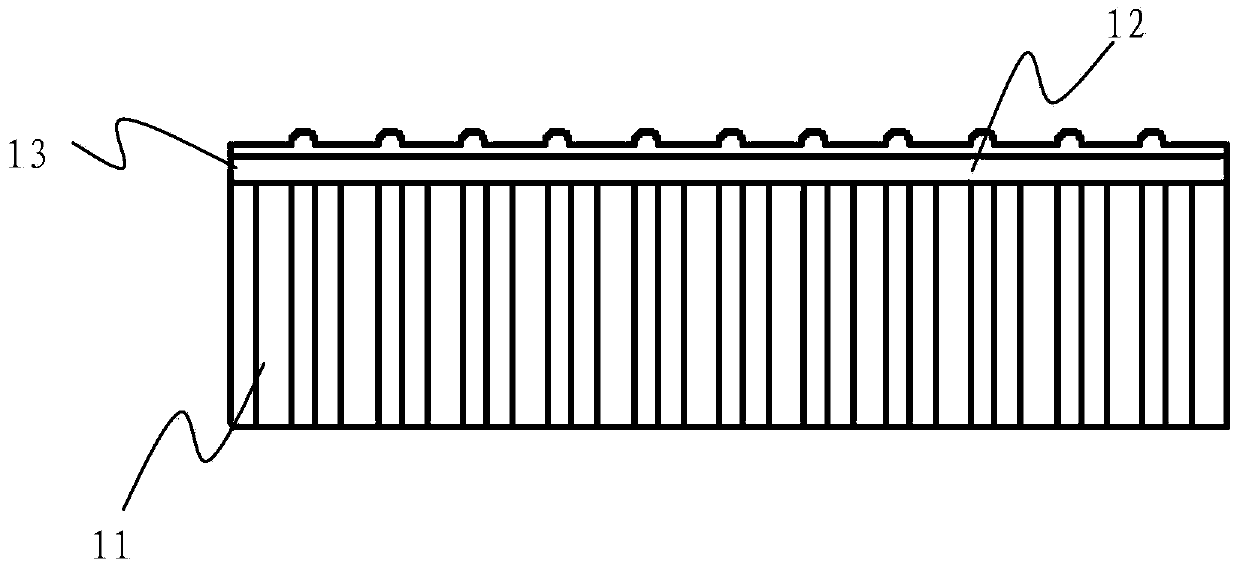

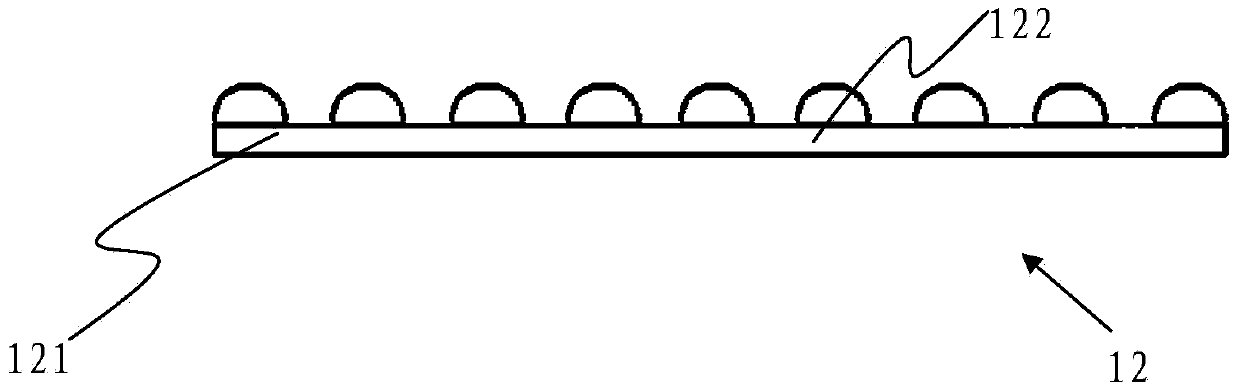

[0016] see first figure 2 As shown, the present invention discloses an OLED light-emitting layer structure that can avoid color shift, including an OLED light-emitting layer 11 and a polarizer 13 arranged on the OLED light-emitting layer 11, and the OLED light-emitting layer 11 further includes sequentially arranged Red, green, and blue three-color blocks, wherein, a coupling film 12 is further provided on the polarizer 12, combined with image 3 As shown, the coupling film 12 includes a bottom film 121 and gate-shaped protrusions 122 attached on the bottom film 121 . The grid-shaped protrusions 122 correspond to the color gamut where color shift occurs in the red, green, and blue color blocks of the OLED light emitting layer 11 . The grid-shaped protrusions 122 on the coupling film 12 increase or decrease the amount of light outpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com