Low penning gas loss sealing-in exhausting and gas-filling vacuum system for PDP

A vacuum system, low-loss technology, applied in the manufacturing field, to achieve the effect of reducing production costs, good economic promotion benefits, and obvious inflatable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

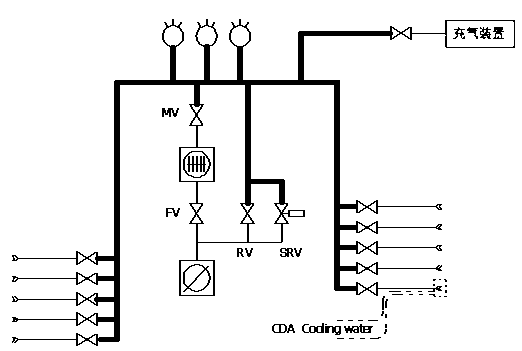

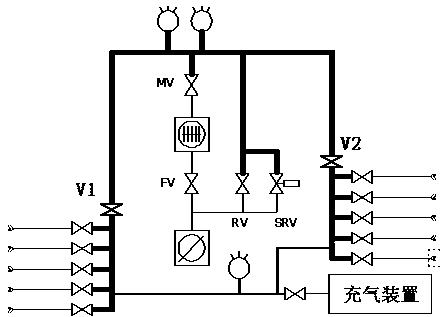

Image

Examples

Embodiment

[0020] The vacuum system provided by the present invention performs PDP sealing, degassing, inflating and then sealing off. The main steps of making are as follows:

[0021] After the PDP is sealed and fully baked and exhausted to the specified vacuum degree, close the main vacuum valve and fill the vacuum system with Penning discharge gas at a certain rate until the pressure reaches 360Torr;

[0022] Seal off the PD that has been inflated;

[0023] Remove the remaining Penning discharge gas in the vacuum system, and the system returns to vacuum state.

[0024] Through the above-mentioned conventional process to manufacture plasma display screens, the volume of the main pipe of the original conventional sealing and charging vacuum system that needs to be filled with Penning gas is about 17.7L, which is reduced to about 2.4L after adopting the structure of the sealing and charging vacuum system of the present invention; PDP is inflated Branch pipe volume (fixed gas loss) is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com