Diagonal-flow constant-temperature flameless burner

A flameless combustion and oblique flow technology, which is applied in the direction of burners, gas fuel burners, combustion types, etc., to achieve high flow velocity, ensure service life, and reduce pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and embodiments.

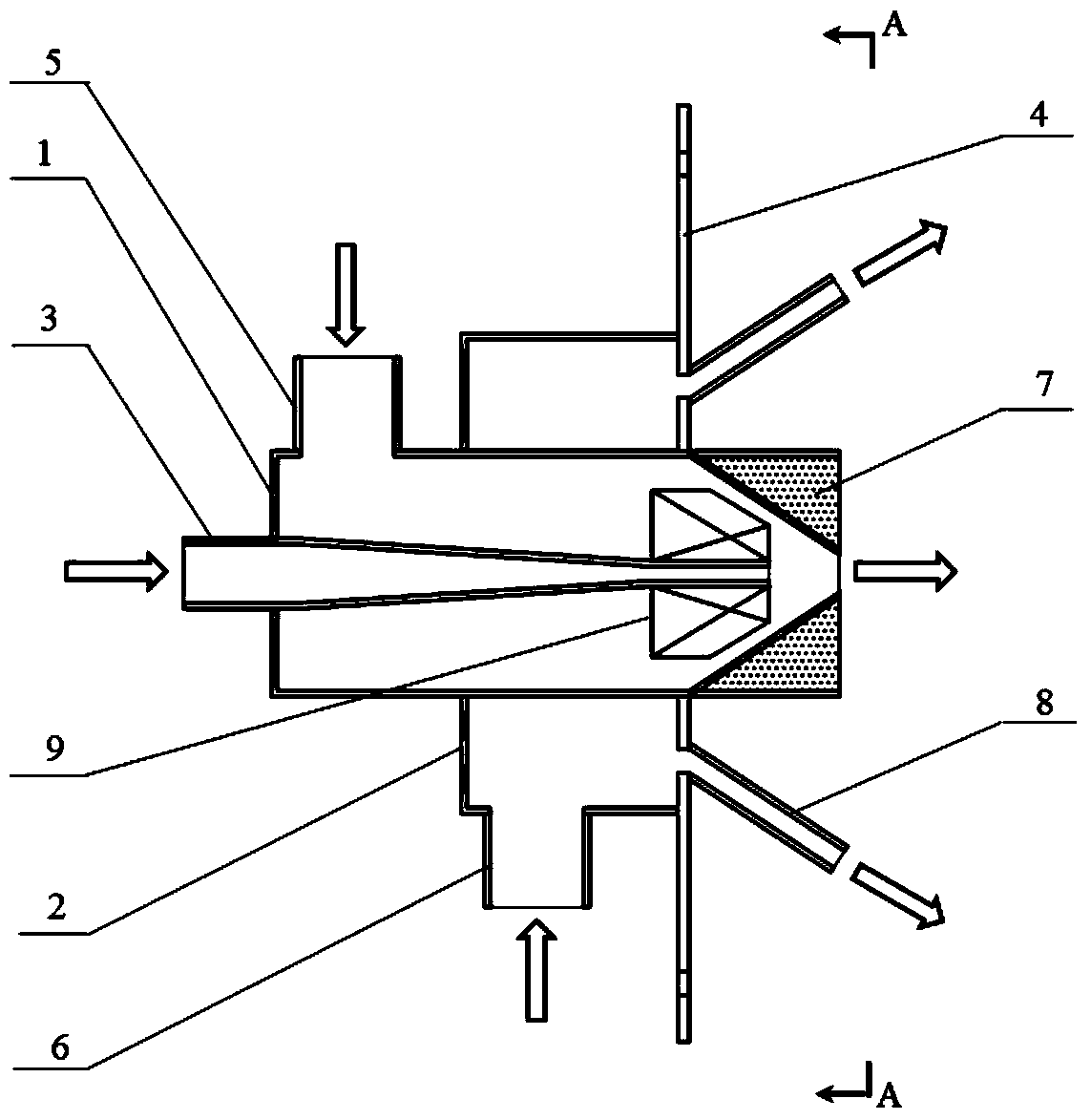

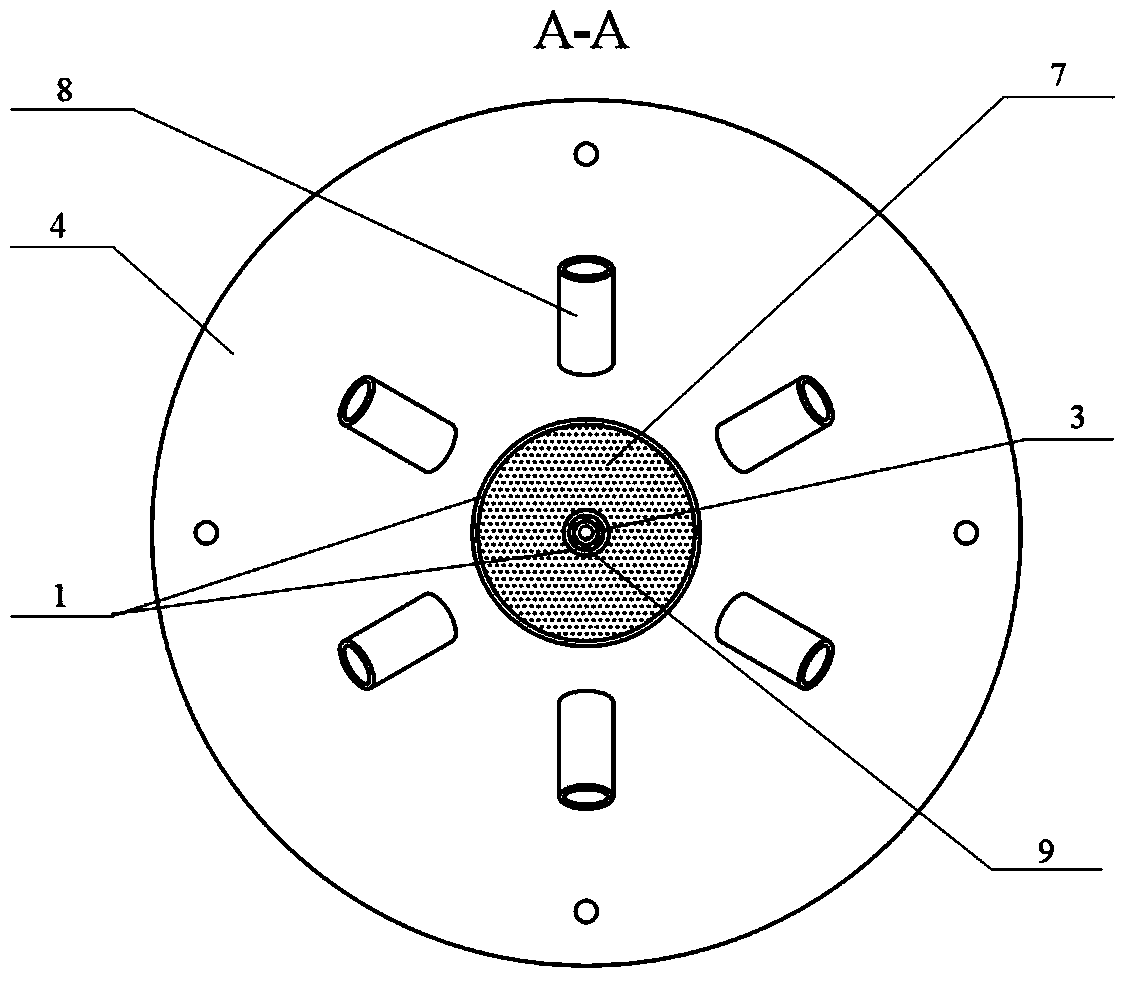

[0015] Such as figure 1 As shown, the present invention includes an inner tube 1, an outer tube 2, a central tube 3, and an annular baffle 4. Among them, the inner cylinder 1 is arranged horizontally, one end side of which is connected with an inner cylinder inlet pipe 5, and the other end extends into the combustion furnace (not shown in the figure), and is connected to the combustion furnace through the annular baffle 4 sleeved outside the inner cylinder Fasten the connection. The part of the inner cylinder 1 located in the combustion furnace adopts an inner and outer double-layer cylinder wall structure. The inner cylinder wall is tapered and has an air outlet at the end. The outer cylinder wall maintains the original cylinder shape. , The ring-shaped triangular groove formed by the outer cylinder wall is filled with refractory materials to form a refractory fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com