Spiral rotor and spiral expansion mechanism

A screw cone and rotor technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as low energy utilization efficiency, and achieve the effect of avoiding thermal energy loss, preventing leakage, and improving thermal energy utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described below in conjunction with the accompanying drawings.

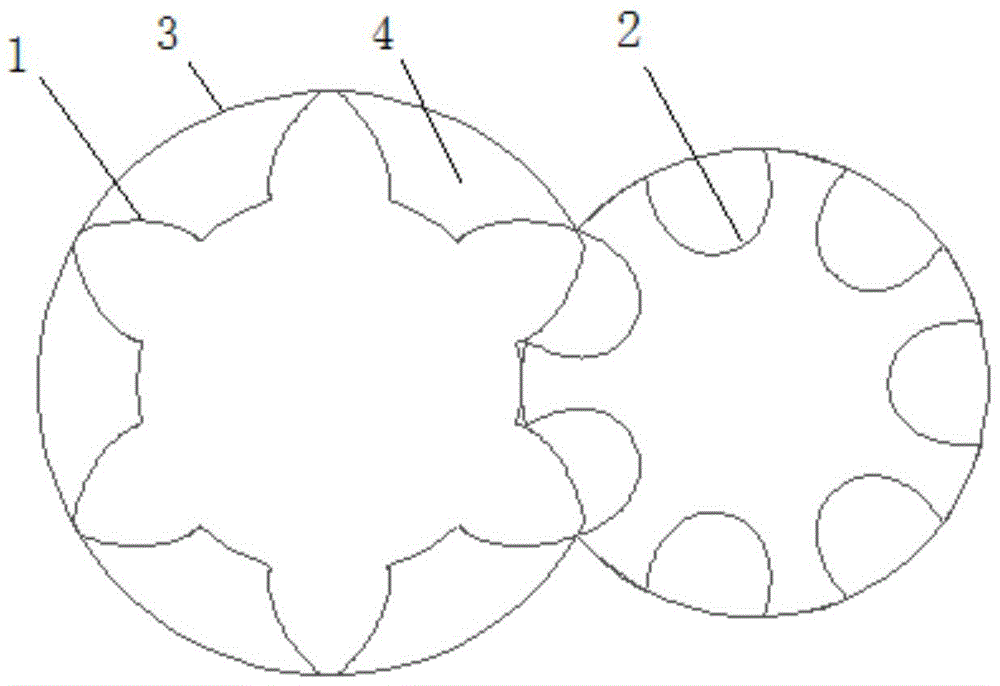

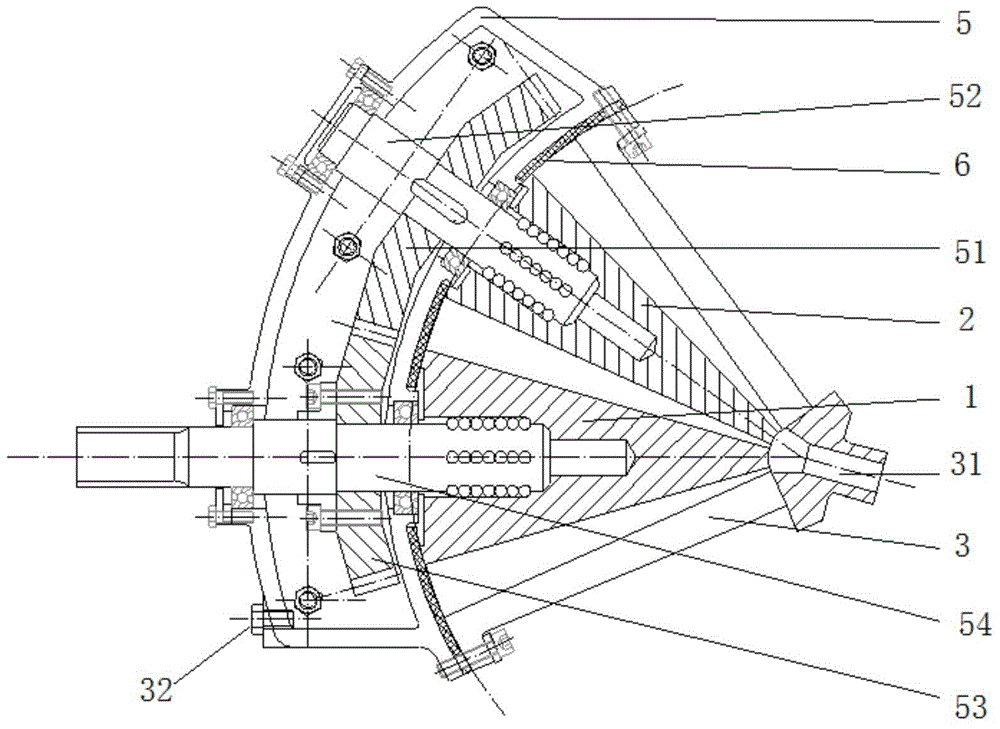

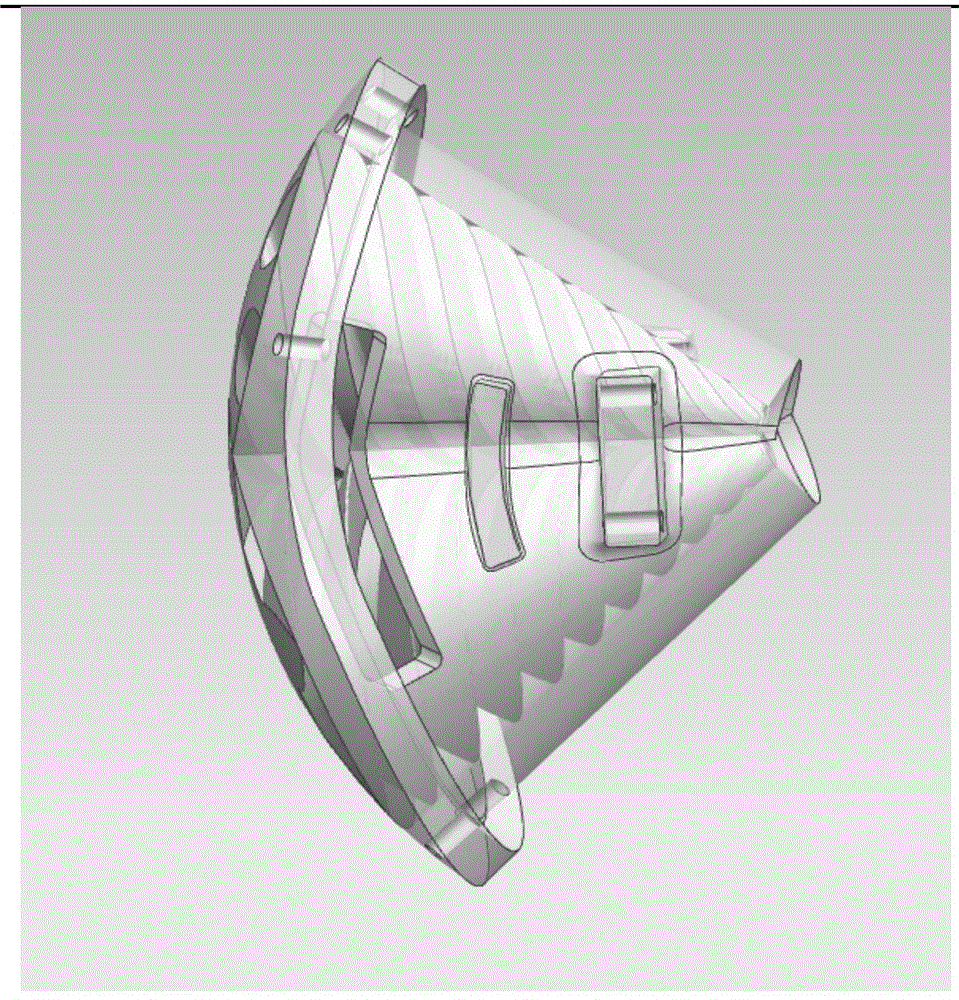

[0043] like figure 2 , image 3 As shown, the spiral cone rotor of the present invention includes a convex rotor 1 and a concave rotor 2 that rotate in opposite directions and have overlapping areas, and a casing 3 that wraps them together. The convex rotor 1 and the concave rotor 2 are screw-cone rotors with tapered profiles gradually converging along the axis of rotation, corresponding to them, such as Figure 4 The housing 3 shown has a double inner cone. The rotation axes of the convex rotor 1 and the concave rotor 2 intersect, and the angle between the two axes is 30°-60°. like Figure 5 As shown, the conical surface of the convex rotor 1 is provided with helically extended convex teeth 11 from the large end to the small end, and the concave rotor 2 is provided with grooves 21 in the same way, the curved surface of the convex teeth 11, the curved surface of the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com