Concentrated sulfuric acid negative pressure acid unloading system

A concentrated sulfuric acid, negative pressure technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of non-compliance with environmental protection and safety, high speed of acid removal, difficult to control, etc., to achieve safe and reliable acid removal process, acid removal. The effect of slowing down the speed and saving the height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

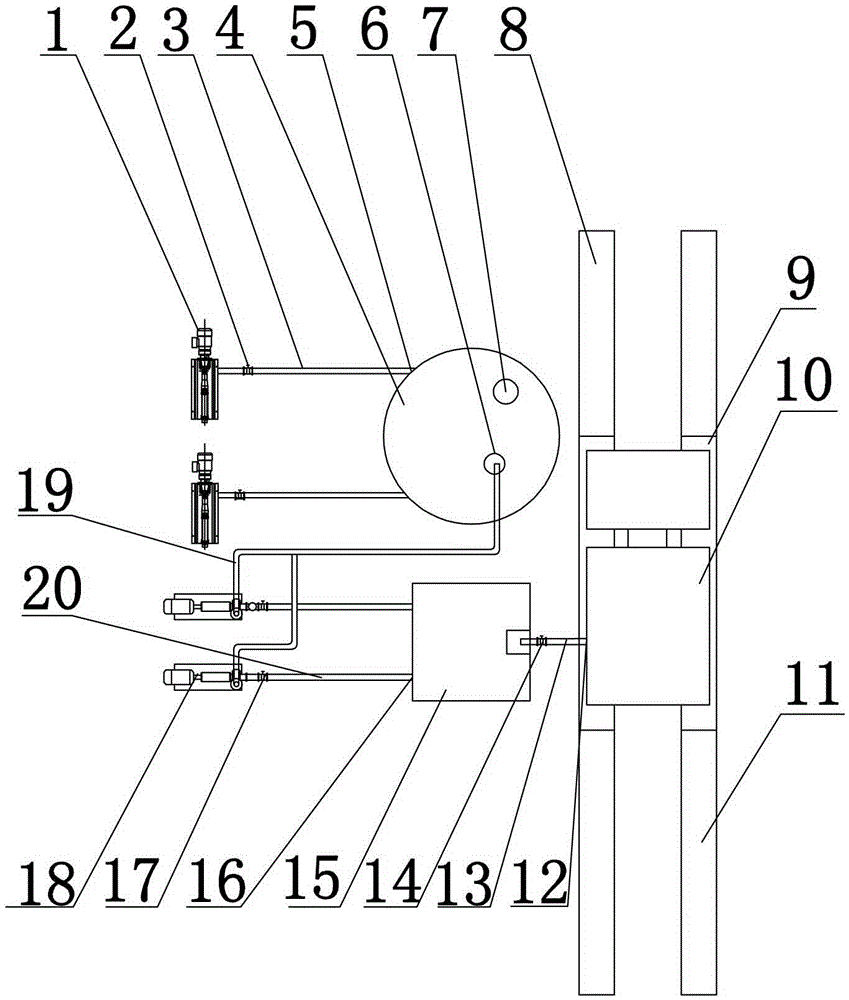

[0020] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] like figure 1 As shown, the concentrated sulfuric acid negative pressure acid unloading system of the present invention is characterized in that it is mainly composed of an acid unloading device, an acid storage device connected with this acid unloading device through an acid unloading pipeline 19, and two acid storage devices connected with this acid storage device Composed of eccentric screw pump 1 and control box,

[0022] The acid unloading device includes an acid tank car support platform, an acid tank car 10 is arranged on the acid tank car support platform, and an acid unloading tank 15 connected to the acid tank car outlet 12 at the bottom of the acid tank car 10 through a connecting pipe I13, and the acid tank car 15 connected to the acid tank car The outlet 16 of the acid unloading tank at the bottom of the acid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com