An auger for easy welding

A welding and axis coincidence technology, applied in packaging and other directions, can solve the problems of wrong side, unreliable welding of auger blades, easy cracks, etc., and achieves the effect of reliable installation, simple structure and enhanced fastening force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

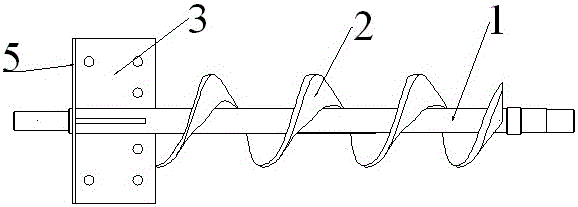

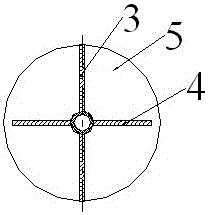

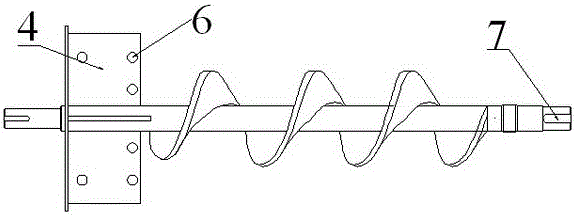

[0024] Such as figure 1 , figure 2 as well as image 3 As shown, an auger that is convenient for welding includes an auger shaft 1, an auger blade 2 welded on the auger shaft 1, and also includes a first mounting plate 3 and a second mounting plate 4. The first The mounting plate 3 and the second mounting plate 4 are fixed on one end of the auger shaft 1 and arranged in a cross around the auger shaft 1; the first mounting plate 3 and the second mounting plate 4 are evenly arranged with N mounting holes 6, N=6, three are evenly distributed up and down relative to the auger shaft 1; the end of the first mounting plate 3 and the second mounting plate 4 away from the auger blade 2 is also fixed with a retaining ring 5, and the axis of the retaining ring 5 is in line with the The axis of the auger shaft 1 coincides; the length of the first mounting plate 3 is equal to the diameter of the retaining ring 5, and the length of the second mounting plate 4 is smaller than the diamete...

Embodiment 2

[0028] The same as embodiment 1, the difference is that the first mounting plate 3 and the second mounting plate 4 are evenly arranged with four mounting holes 6, which reduces the number of punched holes and reduces the cost.

Embodiment 3

[0030] The same as in embodiment 1, the difference is that the first mounting plate 3 and the second mounting plate 4 are evenly arranged with 8 mounting holes 6, which can ensure a more stable auger shaft and enhance the welding quality of the auger shaft and blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com