Blade swing mechanism and marine cycloidal propeller comprising blade swing mechanism

A technology of cycloid propeller and swing mechanism, which is applied in the direction of rotary propeller, rudder steering, etc., can solve the problems of inability to meet the operational flexibility of small ships, inconvenient use of the hydraulic system, and low control precision of the hydraulic system. Achieve the effect of convenient software maintenance, simple structure and good real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

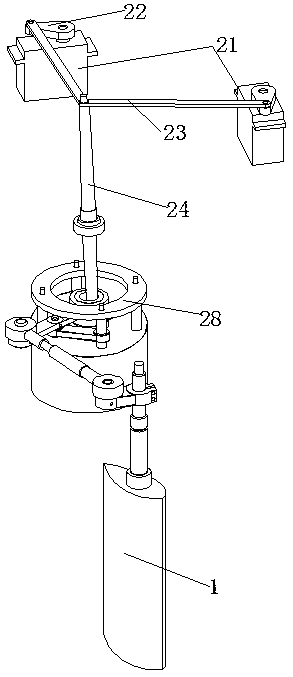

[0040] Such as figure 1 and figure 2 Shown is a schematic structural view of the blade swing mechanism in the embodiment of the present invention.

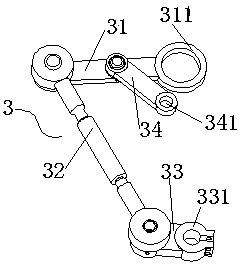

[0041] The blade swing mechanism provided by the present invention includes at least one fixed steering gear 21 , an adjusting rod 24 connected to the steering gear through a driving rod 22 and a driven rod 23 , and a link mechanism 3 for connecting the adjusting rod and the corresponding blade 1 .

[0042] One end of the active rod 22 and one end of the driven rod 23 are mounted together through hinged joints, the other end of the active rod is fixedly installed with the power output shaft of the steering gear, the other end of the driven rod is fixedly installed with the upper end of the adjustment rod 24, and the middle part of the adjustment rod 24 The suit has an axially fixed joint bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com