Reclaimed rubber desulfuration masticator

A kneader, reclaimed rubber technology, applied in recycling technology, plastic recycling, etc., can solve the problems of inability to carry out continuous operation, difficult waste gas collection, low work efficiency, etc., to strengthen kneading efficiency and desulfurization efficiency, saving energy The effect of equipment operation energy consumption and convenient centralized collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

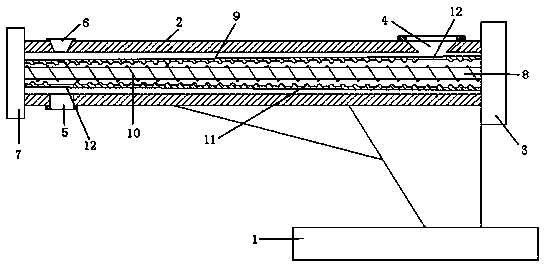

[0008] Such as figure 1 As shown, a reclaimed rubber desulfurization kneader is composed of a frame 1, a protective casing 2, a transmission mechanism 3 and a desulfurization mechanism. The protective casing 2 and the transmission mechanism 3 are installed on the frame 1. The protection A feeding port 4 is provided above the end of the housing 2, a discharge port 5 is provided at the lower part of the front end, an exhaust port 6 is provided at the upper part, and a support sleeve 7 is provided at the front end. The desulfurization mechanism is installed inside the protective housing 2, and the desulfurization The mechanism is composed of a mandrel rotor 8 and a covering rotor 9, wherein the mandrel rotor 8 is nested inside the covering rotor 9, and the mandrel rotor 8 and the covering rotor 9 are coaxial, and the cross section of the covering rotor 9 is equal to Waist trapezoidal, the distance between the end and the mandrel rotor 8 is 2-5 cm, and the distance between the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com