Depth self-adjusting type corn inter-row weeding machine

A self-adjusting, weeding machine technology, applied in the field of agricultural machinery research, can solve the problems of large leaf damage, unsuitable operation and low operation efficiency of corn seedlings, so as to overcome the inconvenience of manual operation, reduce the high operation intensity and solve the operation efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

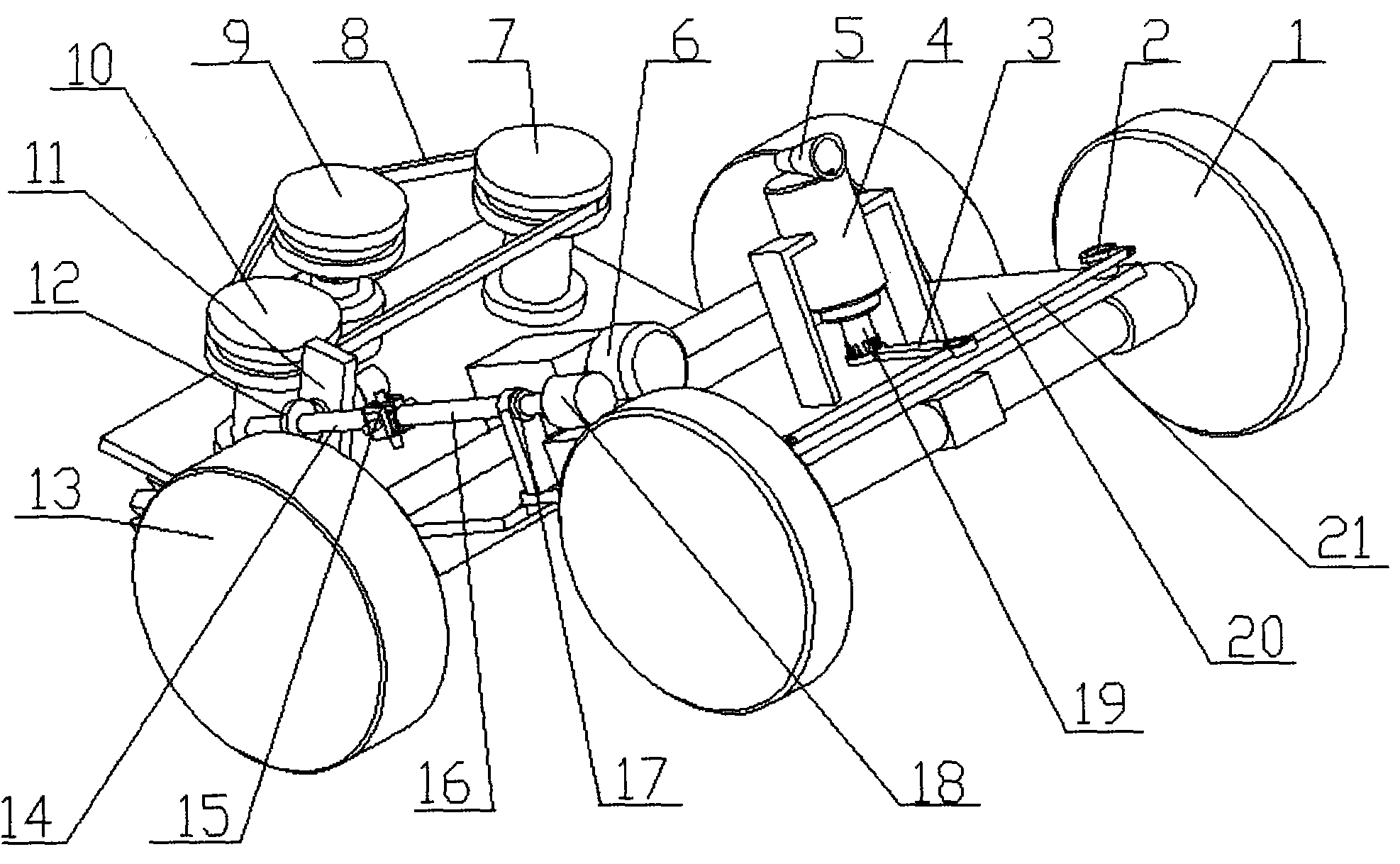

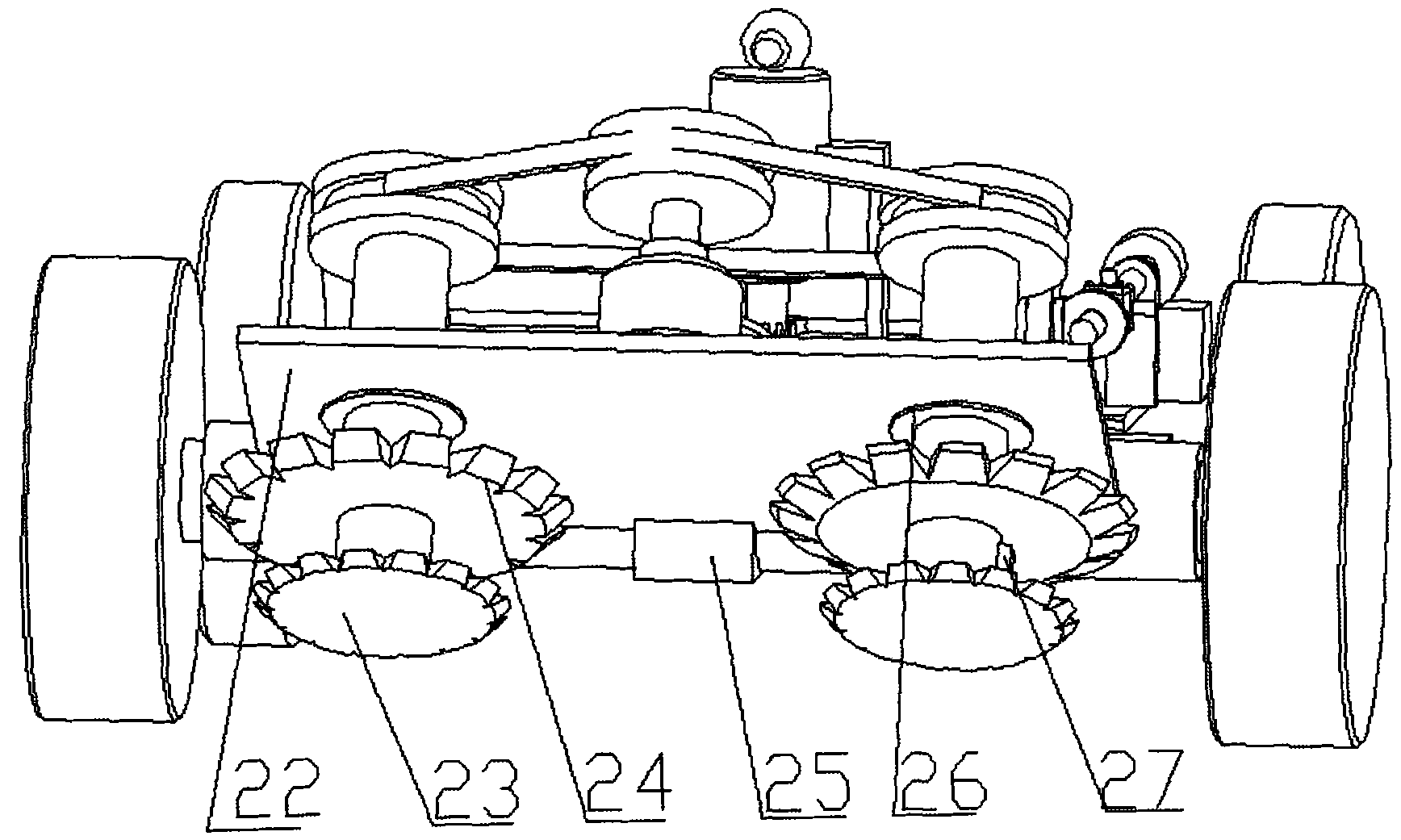

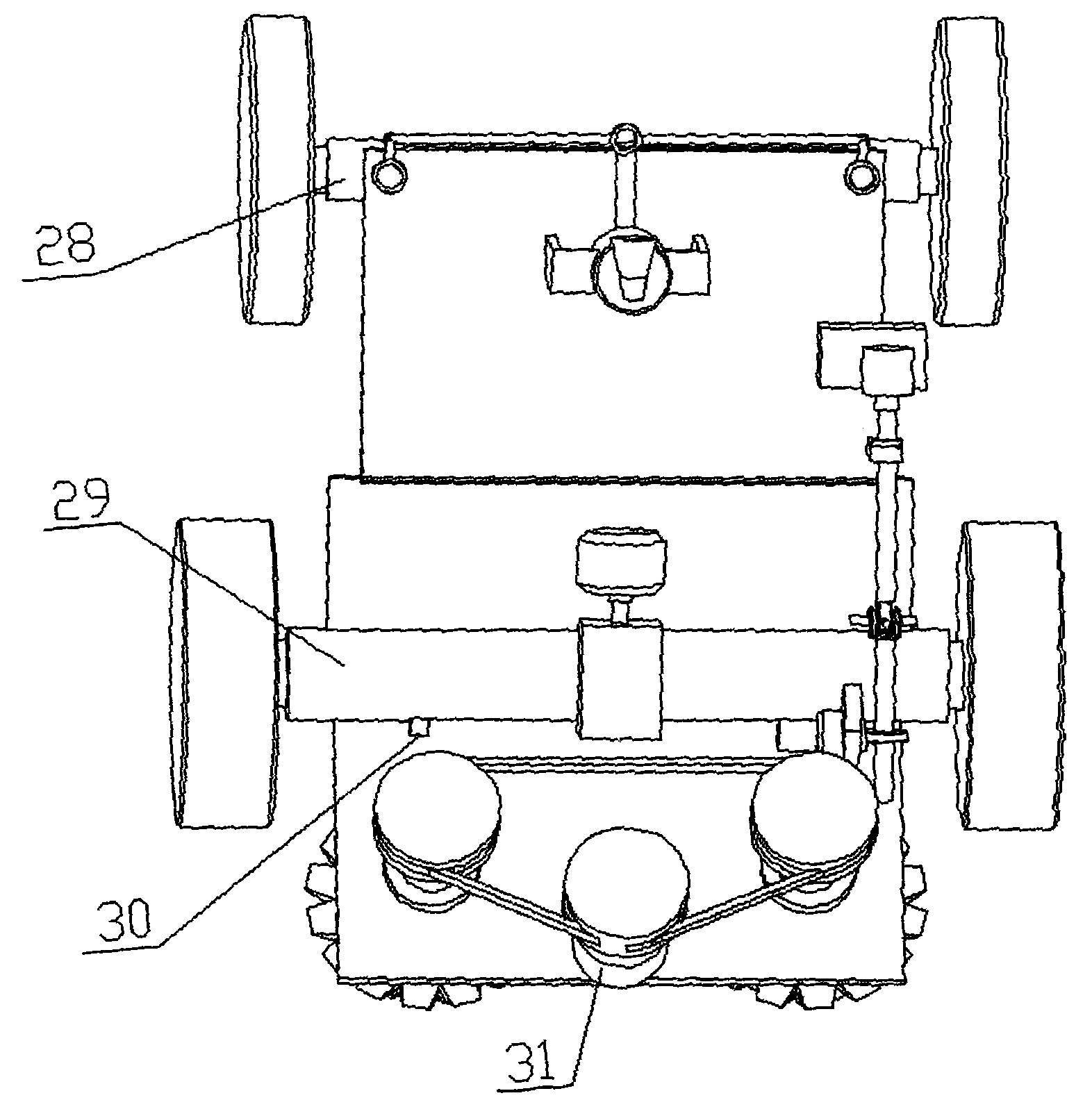

[0016] Attached below figure 1 , attached figure 2 , attached image 3 The present invention is described further:

[0017] as attached figure 1 A deep self-adjusting corn row weeder is shown, including front wheel 1, steering rod 2, shift fork 3, steering motor 4, vision sensor 5, driving motor 6, left passive pulley 7, V-belt 8, driving Pulley 9, right driven pulley 10, support plate 11, screw nut 12, rear wheel 13, working screw 14, coupling 15, driving screw 16, support bearing 17, depth adjustment motor 18, spline shaft 19. Frame 20, pull rod 21, blade fixing plate 22, weeding blade 23, grass cutting blade 24, rear axle differential 25, bearing 26, depth sensor 27, front axle 28, rear axle 29, hinge 30, working motor 31, characterized in that: one end of the steering rod 2 and the pull rod 21 are hinged, the other end of the shift fork 3 and the pull rod 21 is hinged, the spline shaft 19 cooperates with the shift fork 3, and the steering motor 4 and the spline shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com