Method and fossil-fuel-fired power plant for recovering a condensate

A technology for fossil fuels and power plants, applied in separation methods, chemical instruments and methods, through absorption, etc., can solve problems such as high investment and operating costs, high costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

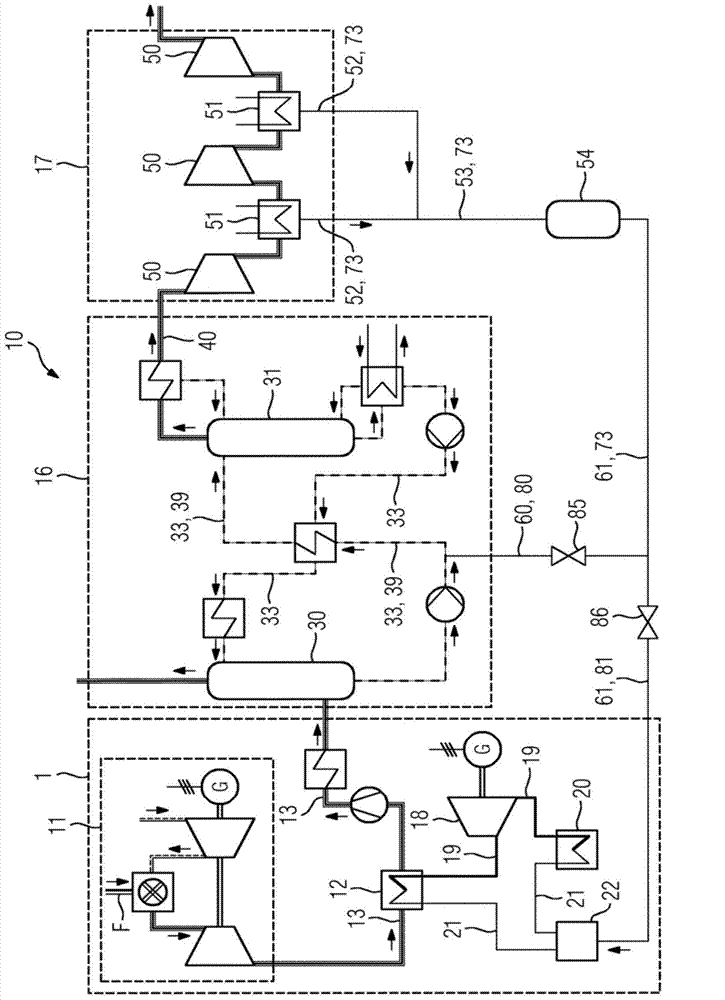

[0020] figure 1 Represents a fossil fuel-burning power station 10, which has a gas turbine equipment as a combustion device 11, a waste heat boiler 12 connected to the gas turbine downstream of the combustion device 11 through a flue gas channel 13, a condenser 20, a soft water preparation device 22, connected to the smoke CO in air channel 13 2 Separator 16, and connected to CO 2 The compressor 17 downstream of the separator 16 has a certain number of compression stages and intermediate cooling stages 50 and 51.

[0021] The fossil fuel is burned in the gas turbine of the combustion device 11, and CO-containing 2 Smoke. The flue gas is supplied to the waste heat boiler 12 through the flue gas channel 13 for generating steam 19. The steam 19 is fed to a steam turbine plant 18 not shown in detail here, where the steam 19 is expanded and then sent to the condenser 20 and reduced in pressure into feed water 21. After the steam 19 is condensed in the condenser 20, the feed water 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com