Stator core, split core block, stator manufacturing method and rotary electric machine

A stator core and split core technology, which is applied in the manufacture of stator/rotor bodies, motor generators, electrical components, etc., can solve the problems of increasing stator core iron loss and achieve the effect of reducing iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the stator core, the discrete core group, the method of manufacturing the stator, and the rotating electric machine disclosed herein will now be described in detail with reference to the drawings constituting a part of the present invention. However, the present invention is not limited to the following embodiments.

[0024] (Stator core)

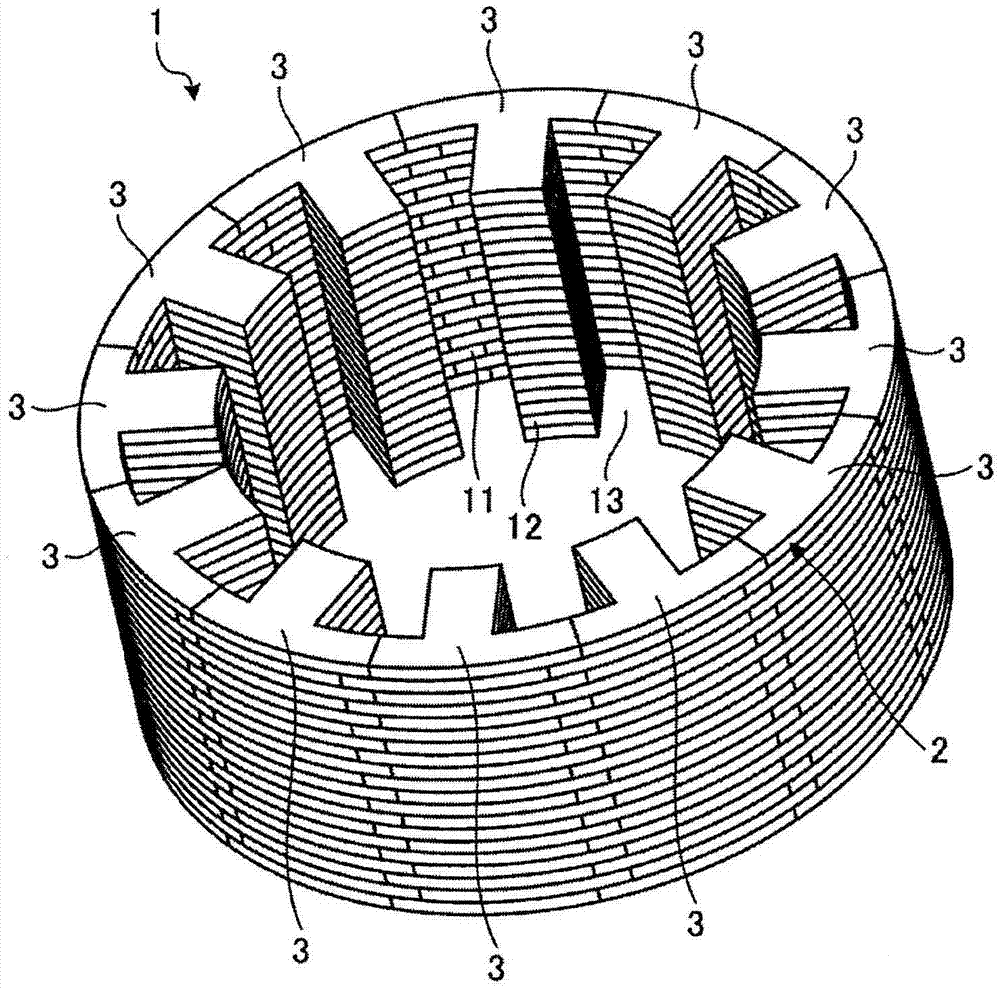

[0025] First, the stator core according to the preferred embodiment will be briefly described with reference to the drawings. figure 1 It is a perspective view showing the stator core 1 according to the preferred embodiment.

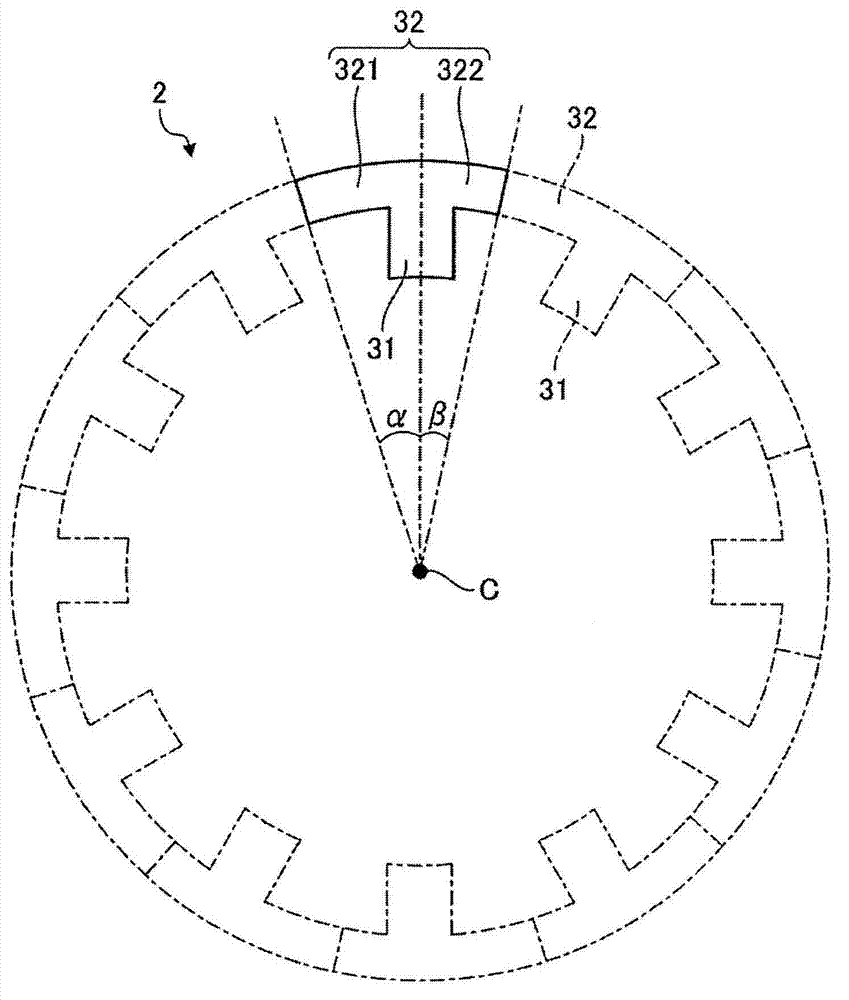

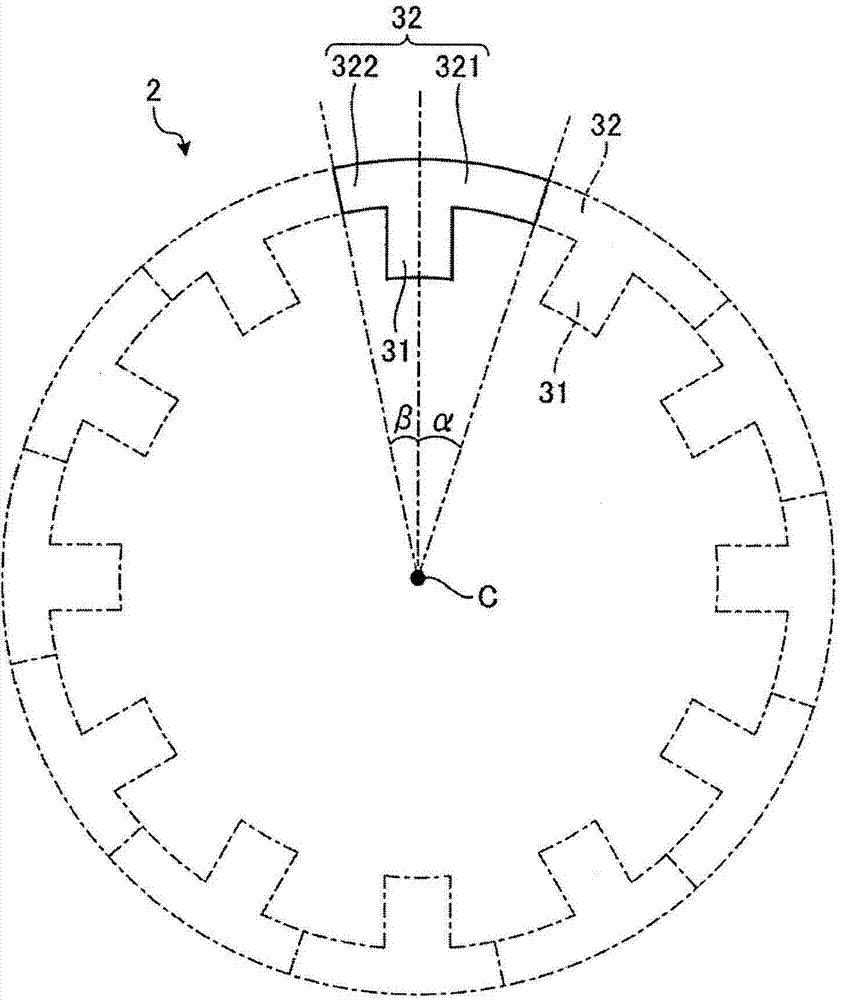

[0026] The stator core 1 according to the preferred embodiment is used in, for example, a motor 10 to be described later (see Picture 11 ). Such as figure 1 As shown in the figure, the stator core 1 is formed by laminating a plurality of metal annular core plates 2 up and down. The number of the core plates 2 laminated in this way can be appropriately set according to desired characteristics. Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com