Bistable permanent magnetic mechanism

A permanent magnet mechanism and bistable technology, applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of increasing the movement conversion link, increasing the difficulty of design, reducing the working efficiency and reliability of the mechanism, and achieving the guarantee Reliability and the effect of improving the suction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

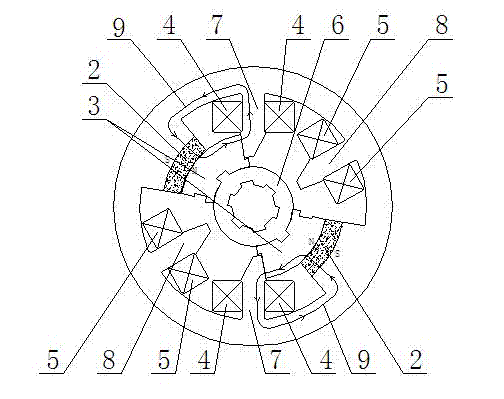

[0019] Such as figure 2 As shown, a bistable permanent magnet mechanism includes an outer yoke 1 with a circular inner cavity and a mandrel 6 arranged at the center of the outer yoke 1, the mandrel 6 is made of a non-magnetic material, Two moving iron cores 3 that are not connected to each other are arranged symmetrically on the circumference of the mandrel 6, and on the inner wall of the outer yoke 1, a closing pole 7 is provided corresponding to both sides of each moving iron core 3 and a gate-opening pole 8, the gate-closing pole 7 and the gate-opening pole 8 are provided with a working surface that can be attracted to the moving iron core 3, and the gate-closing pole 7 and the gate-opening pole 8 are respectively wound with a The moving iron core 3 reciprocates between the closing pole 7 and the opening pole 8, the closing coil 4 and the opening coil 5, and the inner wall of the outer yoke 1 is provided with a coil that is always in contact with the outer surface of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com