A semi-dry desulfurization system and method for a circulating fluidized bed boiler

A circulating fluidized bed and desulfurization system technology, applied in the field of flue gas purification, can solve the problems of waste of calcium-based desulfurizer raw materials, affecting the utilization of calcium-based desulfurizer, blockage of pores on the surface of particles, etc., and achieves low investment and operation and maintenance costs. The effect of improving calcium utilization and saving dehydration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

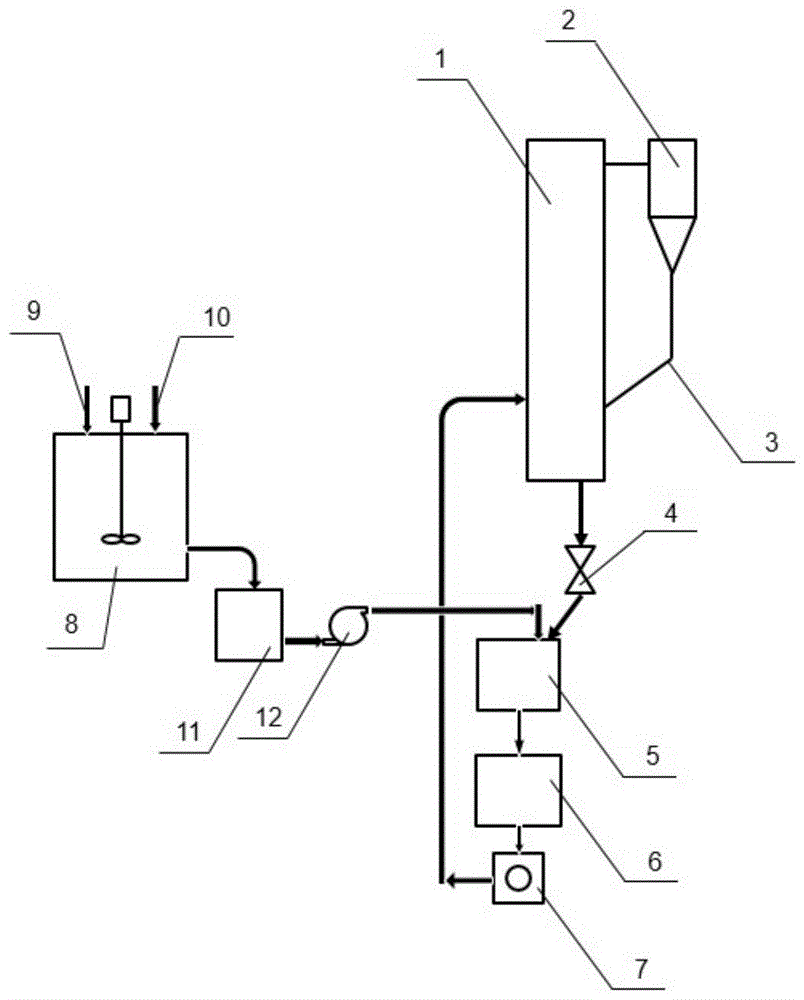

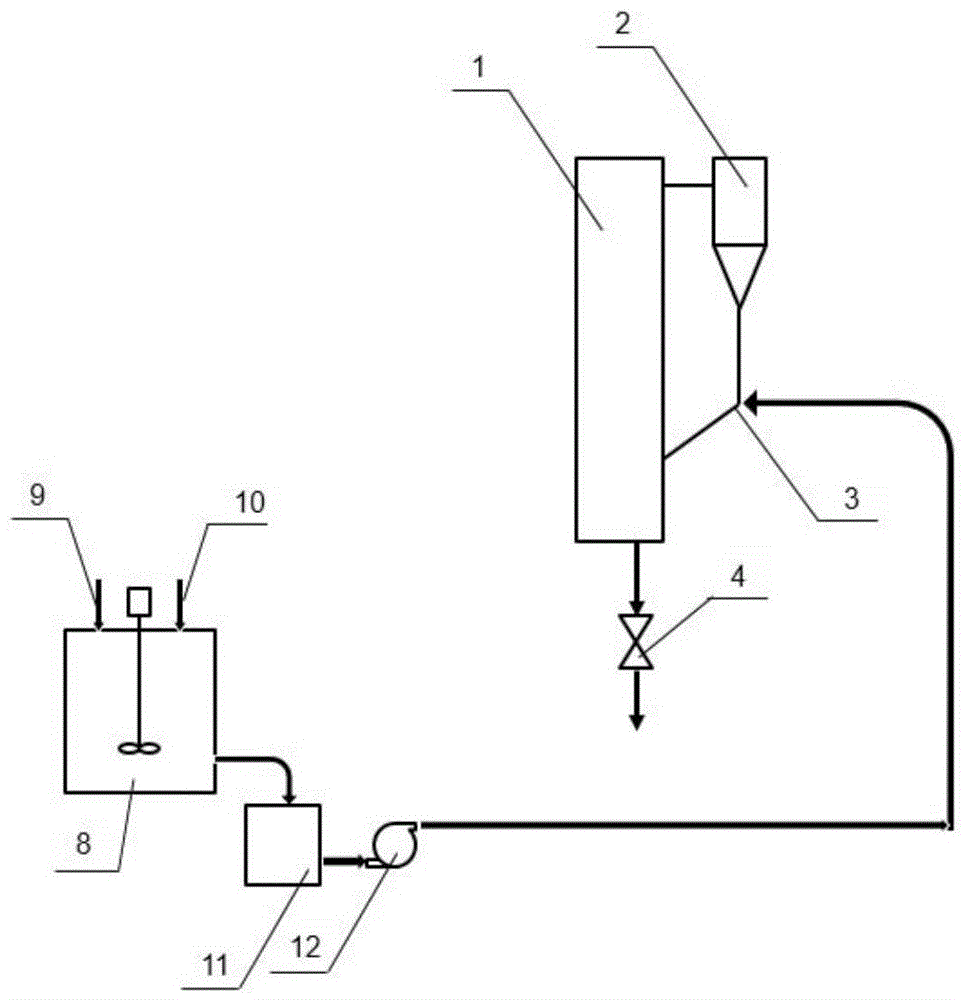

[0021] Further illustrate structure and working process of the present invention below in conjunction with accompanying drawing.

[0022] figure 1 The present invention provides a schematic diagram of the structure and principle of a semi-dry desulfurization system and method for a circulating fluidized bed boiler. The system includes a circulating fluidized bed boiler furnace 1, a gas-solid separator 2, a circulating ash return device 3, Slagging control valve 4, desulfurizer slurry preparation system and desulfurizer addition system; the desulfurizer slurry preparation system includes a pulping tank 8, a slurry storage device 11 and a slurry pump 12, and the pulping tank 8 is provided with quicklime inlet 9 and The water inlet 10, the inlet of the slurry storage device 11 is connected with the slurry outlet of the slurry tank 8 through a valve and a pipeline, and the inlet of the slurry pump 12 is connected with the slurry storage device 11 through a pipeline; the desulfuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com