Double-layer all-steel structure floor with embedded channel steel beams

A technology of embedded grooves and steel structures, which is applied to floors, building components, building structures, etc., can solve the problems of reducing construction efficiency, reflecting the industrialization of buildings and green buildings with a full life, and achieves shortened construction periods and simple structures , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

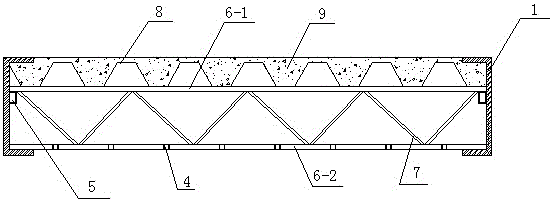

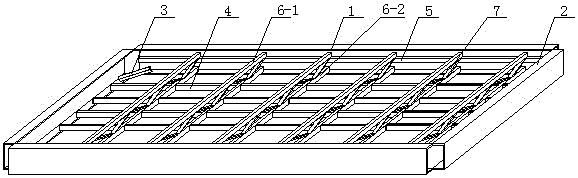

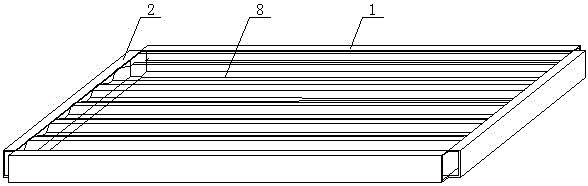

[0013] from Figure 1-Figure 4 It can be seen from the figure that: a double-layer all-steel structure floor with embedded channel steel beams (referred to as double-layer all-steel structure floor), is characterized in that: the double-layer all-steel structure floor with embedded channel steel beams is mainly composed of beams 1 , longitudinal beams 2, transverse ribs 4, auxiliary beams 5, upper purlins 6-1, lower purlins 6-2, diagonal braces 7 and steel panels 8, the beams 1 are symmetrically arranged front and rear two horizontal channel steel beams and The notches are all inward, and the front and rear beams correspond to the front and rear long sides of the floor. The longitudinal beams 2 are symmetrically arranged left and right horizontal channel steel beams and the notches are also inward, and the left and right longitudinal beams correspond to the front and rear long sides of the floor. On the left and right short sides, the cross-sectional size of the channel steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com