Wave pressure sensor embedding device and method

A technology of pre-embedded devices and sensors, which is applied in the direction of basic structure testing, construction, and basic structure engineering, etc. It can solve the problems that the verticality cannot be guaranteed, there is no protection device, and the pressure-bearing surface cannot be fully exposed, so as to achieve true and reliable measurement data. , Guarantee the requirements of burial and avoid the effect of irreversible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the purpose, technical solution and advantages of the present invention clear, the method of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples of implementation.

[0051] 1. Wave pressure sensor embedded device

[0052] 1. Overall structure

[0053] The pre-embedded device of this wave pressure sensor is composed of a combined sleeve and an adjustment base.

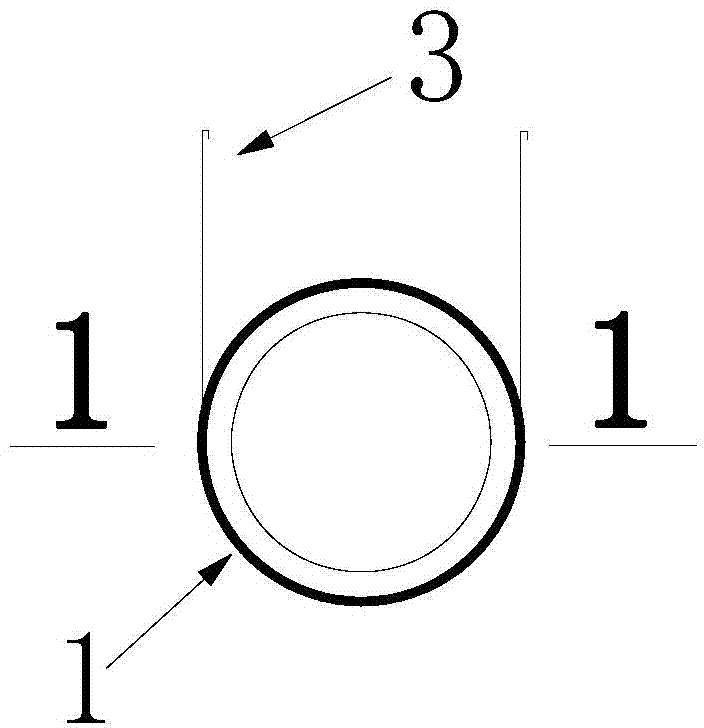

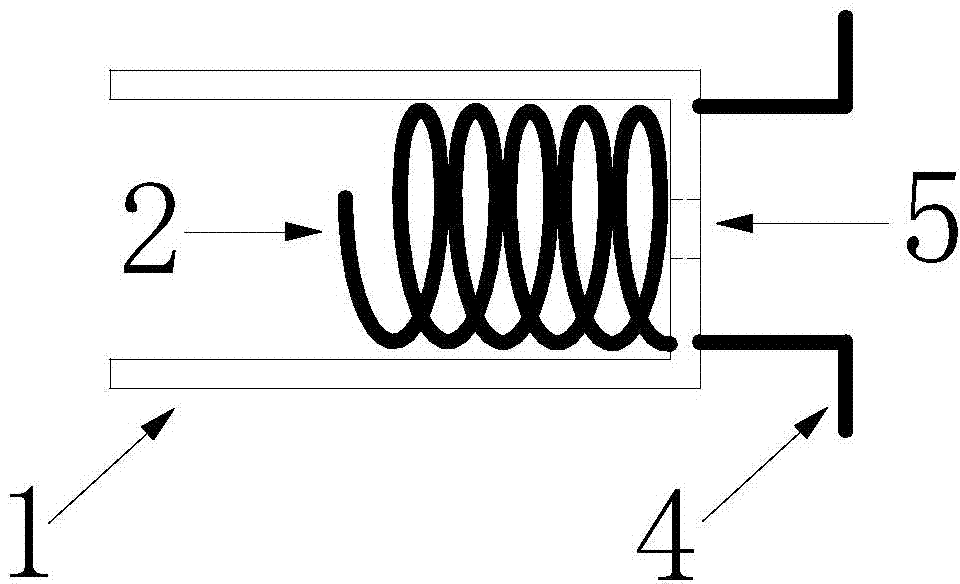

[0054] like Figure 1.1 , 1.2 , The combined sleeve includes a sleeve 1, a spring 2, a bracket 3, a guide wire 4 and a lead wire opening 5.

[0055] Guide steel wire 4 is welded on the right end of sleeve, and spring 2 is fixed on the bottom end steel plate of sleeve 1. The steel plate at the bottom end of the sleeve 1 is provided with a lead hole 5 .

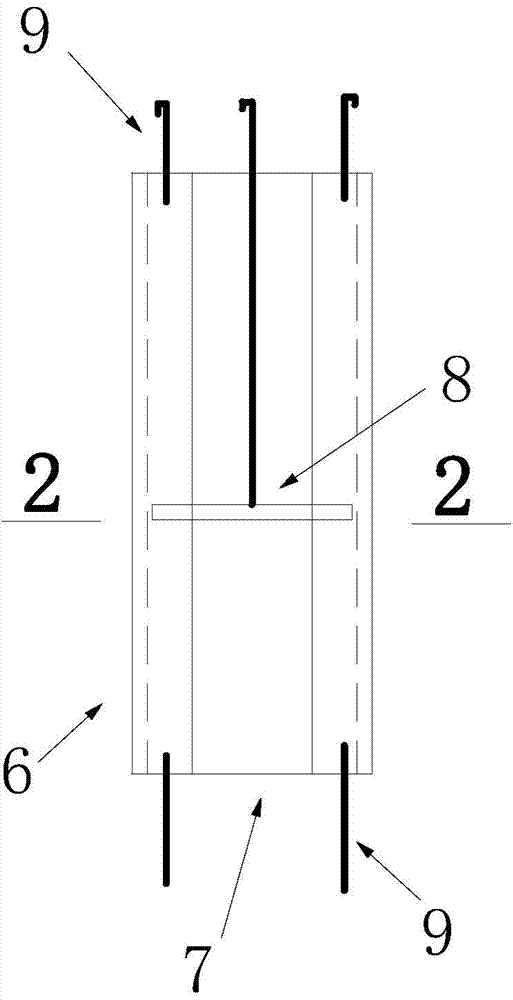

[0056] like Figure 2.1 , 2.2 , The steering base includes a U-shaped guide chute 6, a connecting steel plate 7, a limiting plate 8 and a fixed bracket 9.

[0057]Two U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com