Dial-drawing device and dial-drawing method for trough-type indicating instrument

A technology of indicating instruments and drawing boards, which is applied in the field of substation indicating instruments reforming devices, can solve the problems of low work efficiency, inability to guarantee measurement accuracy, time-consuming and labor-intensive problems, and achieve the effects of automatic control, improved drawing efficiency, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

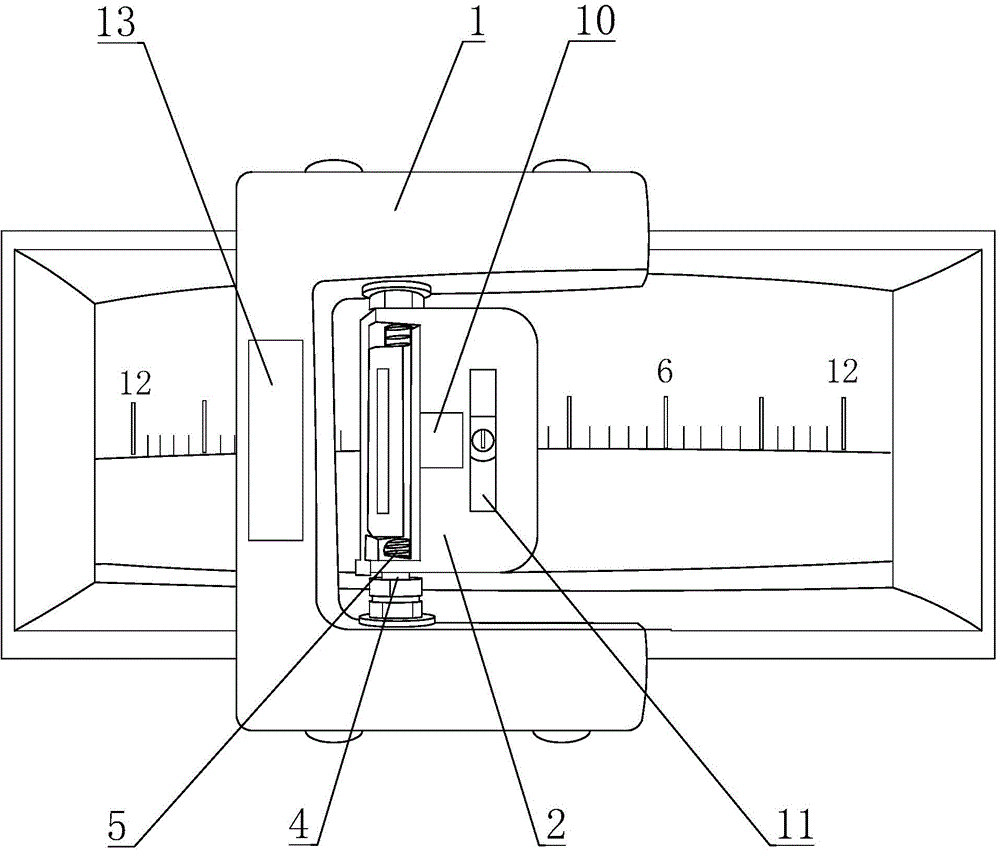

[0029] A trough-shaped indicating instrument drawing board device, comprising a U-shaped sliding frame 1, a drawing positioning system, a telescopic pull rod 6, a fixed suction cup 9, and a drive control system;

[0030] Such as figure 1 As shown, the drawing positioning system includes a drawing platen 2, a drawing motor 10 fixed on the drawing platen 2, a drawing frame 11, and a scanning port 12 arranged on the back side of the drawing platen 2; The rotating shaft 4 provided between the two side arms is connected; the line drawing frame 11 is arranged parallel to the rotating shaft 4, and is slidingly connected with the drawing platen 2, and the middle part of the line drawing frame 11 is fixedly provided with a drawing pen; the drawing motor 10 is connected to the line drawing frame throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com