Lining coating equipment for ductile cast iron pipe

A ductile iron pipe and lining technology, which is applied in the supply device, ceramic molding machine, surface layering device, etc., can solve the problems of easy falling off of the lining, low production efficiency, narrow applicability, etc. The effect of convenient and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

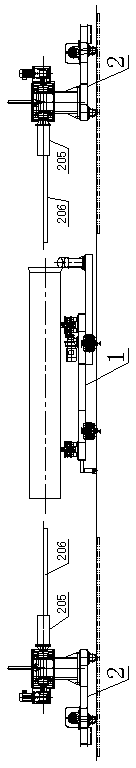

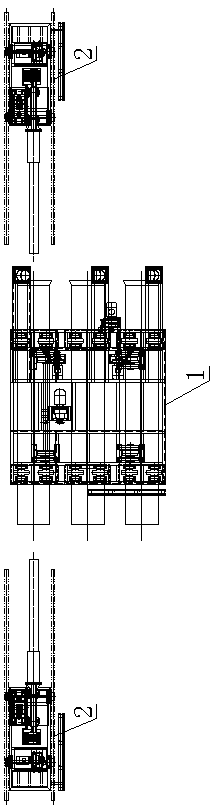

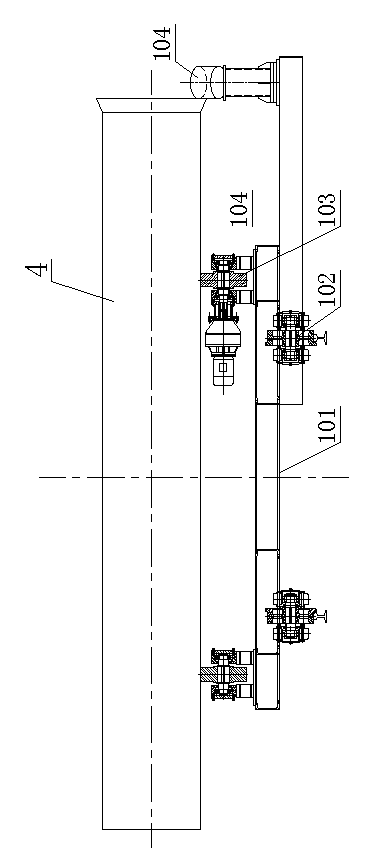

[0032] As shown in the figure, the ductile iron pipe lining equipment is composed of a rotating platform trolley 1, a heating gun 3 and a cloth trolley 2, wherein the rotating platform trolley consists of a frame 101 and a walking wheel set under the frame 101 102 and a plurality of supporting wheel sets 103 arranged on the vehicle frame 101 top. The heating torch 3 is arranged at the position below the vehicle frame 101 corresponding to the support wheel set 103 for preheating the ductile iron pipe 4 . The cloth trolley 2 is arranged on both sides of the vehicle frame 101 respectively. One side of the vehicle frame 101 is provided with a retaining wheel 104 for limiting the axial displacement of the ductile iron pipe 4 . The walking wheel set 102 is composed of a driving wheel set 102a and a passive wheel set 102b. The rotating shaft of the driving wheel set 102a is connected with the output shaft of the motor 105 placed on the vehicle frame 101 through a transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com