Electric tool push rod assembly

A technology of electric tools and push rods, applied in the field of electric tool push rod components, can solve the problem of no device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

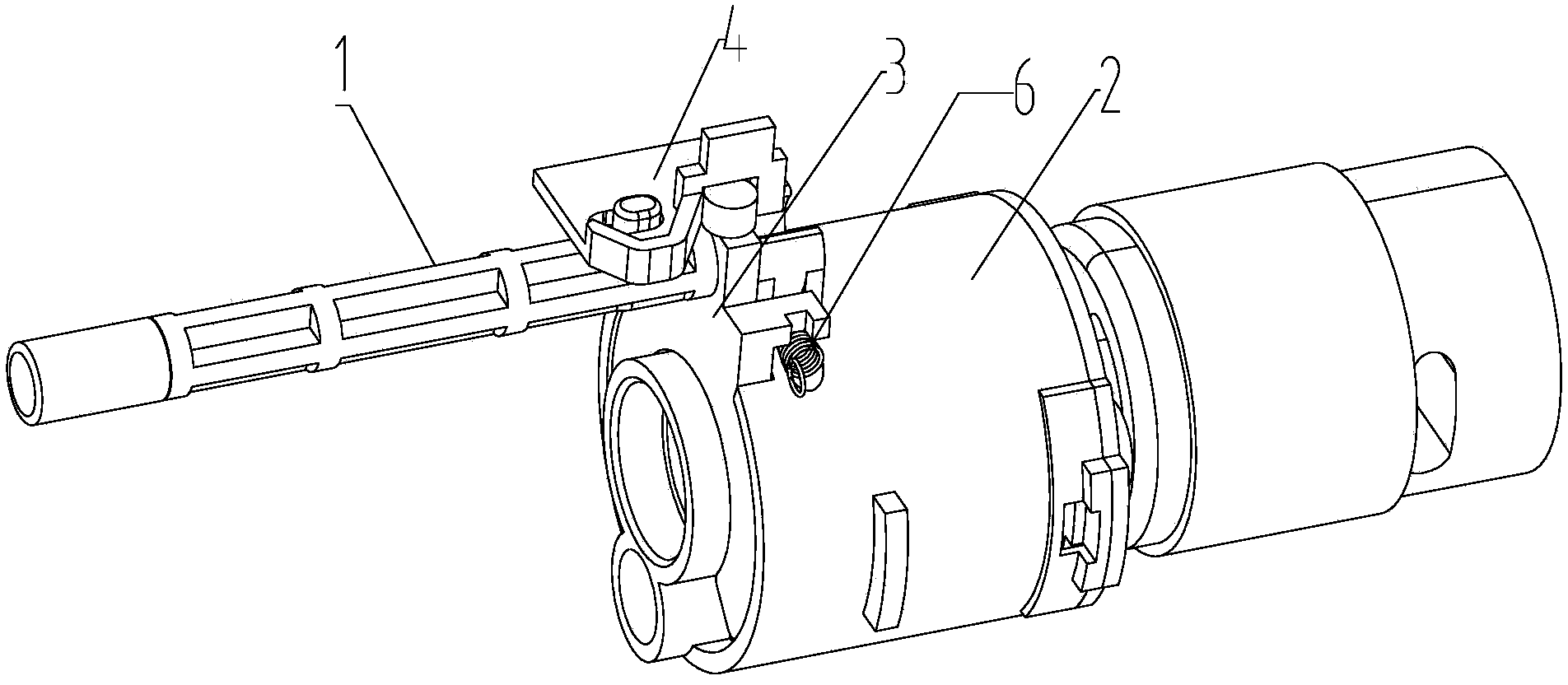

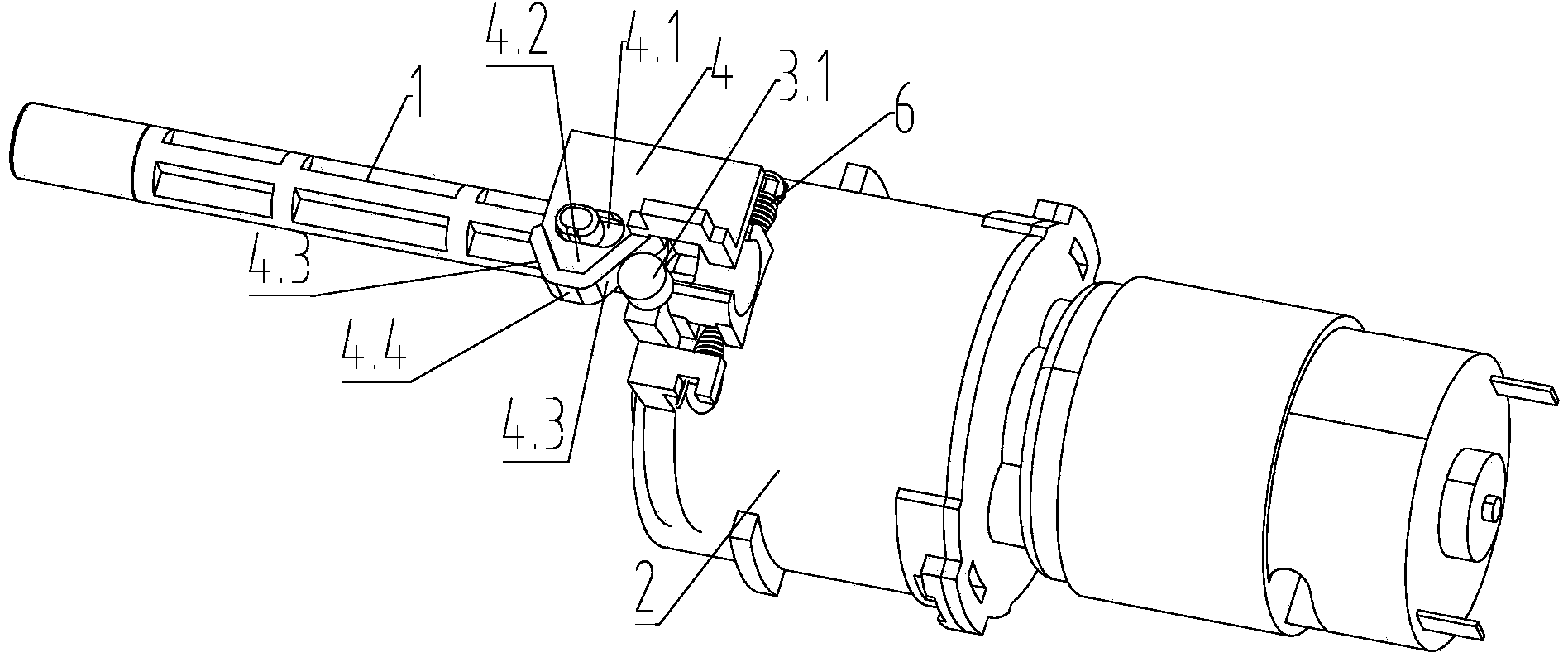

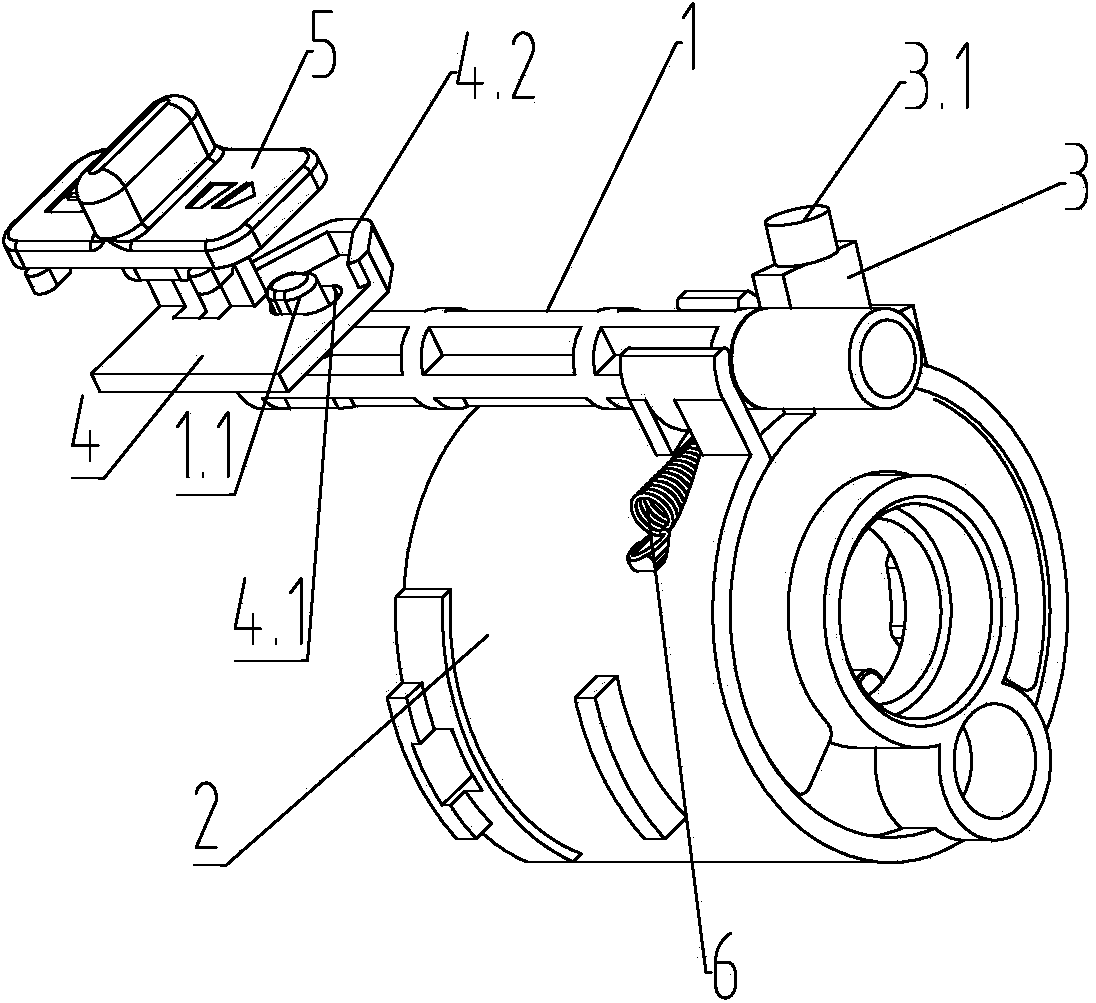

[0020] Such as figure 1 , 2 , 3, the present invention provides a power tool push rod assembly, which includes a push rod 1, the push rod 1 is used to push the tool down to the position of the tool chuck; the drive unit 2 is used to drive the tool chuck to rotate;

[0021] It also includes a push rod catch 3 that is rotatably connected to the drive unit 2, and the plane where its rotation track is located is perpendicular to the axis of the push rod 1. In this embodiment, the drive unit 2 includes a gearbox, and the push rod catch 3 Rotationally connected on the gearbox, the gearbox is a cylindrical structure, the axis of rotation of the push rod catch 3 is the same as the axis of the gearbox, and the push rod catch 3 is also provided with an elastic reset mechanism, which can be pushed in the natural state. The rod stopper 3 faces the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com