Tool for processing drainage wire clip bolt under hot-line mode and hot-line work method of tool

A live treatment and drainage line technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as difficult replacement operations and affecting line reliability, and achieve the effects of improving work efficiency, reducing work costs, and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the drawings.

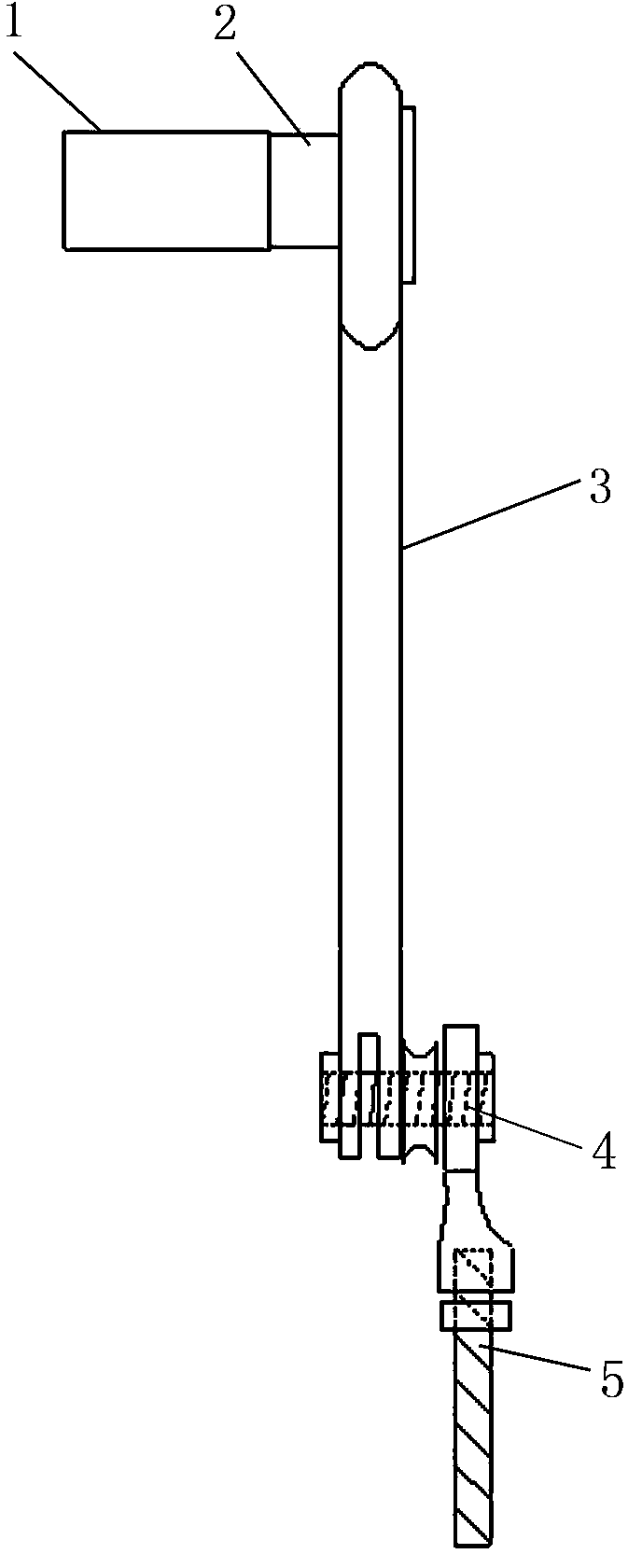

[0030] See figure 1 The tool provided by the present invention for the live treatment of drain wire clamp bolts includes a connecting rod 3, a sleeve for fastening the bolts 1, an insulating rod 5, and the sleeve 1 is detachably connected to one end of the connecting rod 3. The insulating rod 5 is rotatably connected to the other end of the connecting rod 3 through the connecting piece 4, and the insulating rod 5 can rotate 360° around the connecting rod 3. A ratchet 2 is provided between the connecting rod 3 and the sleeve 1 to prevent the bolts from being loosened instead of being tightened. The ratchet 2 is inserted into the connecting rod 3, and the sleeve 1 and the ratchet 2 pass through a square cone (not shown in the figure). Mark) connection. The above-mentioned insulating rod 5 is formed by connecting insulating rod units, and the insulating rod units can be connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com