Automatic control system and control method for coating diameter of optical fiber

An automatic control system and optical fiber coating technology, applied in the sequence/logic controller in the direction of program control, electrical program control, etc., can solve the problem that the adjustment of the fiber coating diameter is not smooth enough, unable to meet the production requirements, etc., to achieve the parameters Stable, meet the requirements of high-speed wire drawing, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

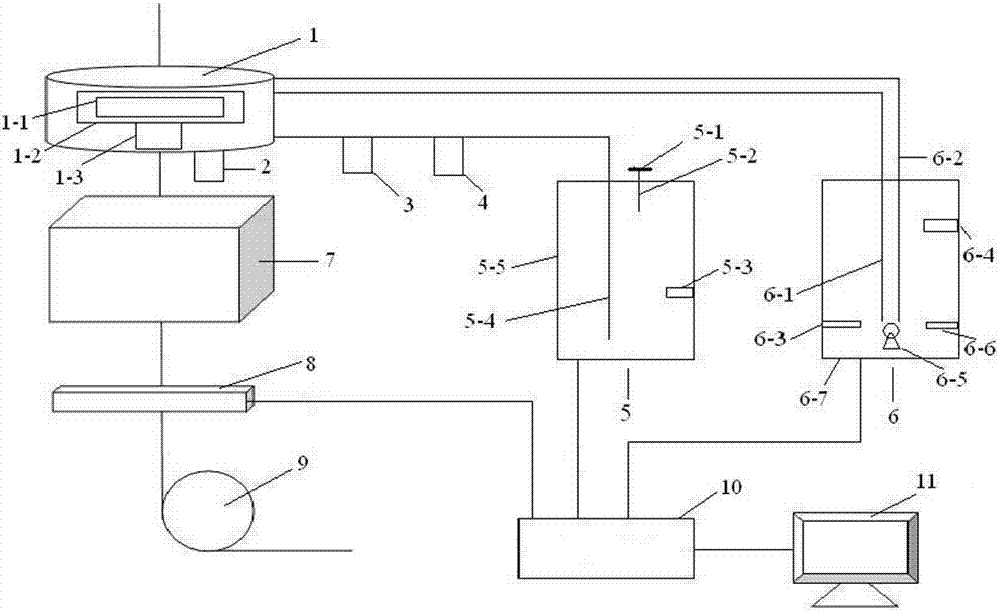

[0030] Refer to attached figure 1 , 2 , an optical fiber coating diameter automatic control system includes an optical fiber coating device (1), a coating device temperature sensor (2), a coating pressure sensor (3), a coating pipe temperature sensor (4), a coating pressing device (5 ), the water bath device (6) of the coating device, the paint curing device (7), the coating diameter gauge (8), the traction device (9), the programmable logic controller (10), and the upper computer (11).

[0031] The optical fiber coating device (1) is provided with a paint box 1-1, and a water bath heating jacket 1-2 is arranged in the paint box. The water bath heating jacket is provided with a water inlet and a return pipe. A coating mold 1-3 is installed below the paint box.

[0032] The water bath device (6) of the coating device includes a water inlet pipe 6-1, an outlet pipe 6-2, an electric heating pipe 6-3, a liquid level sensor 6-4, a water pump 6-5, a temperature sensor 6-6 and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com