Construction method for casting prefabricated mass concrete beam by using special support devices

A technology of large-volume concrete and supporting devices, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of poor operability, low accuracy, engineering accidents, etc., to ensure construction quality, simple operation, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0020] A construction method for pouring an assembled mass concrete beam with a special supporting device, the method comprising the following steps:

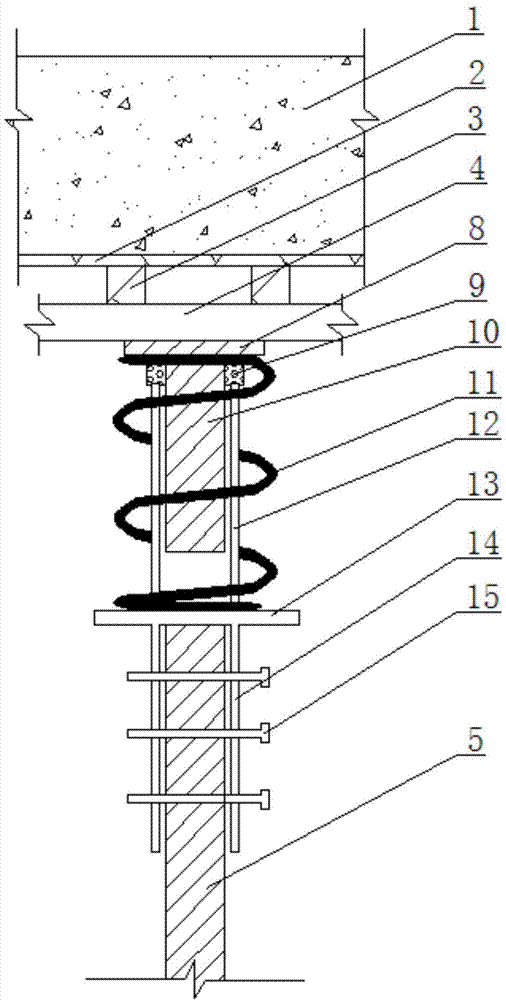

[0021] (1) Calculate the usage quantity of the special support device, the shear modulus of the spring 11 in the special support device and the elastic modulus of the spring according to the total weight including the assembled mass concrete beam 1 and the template;

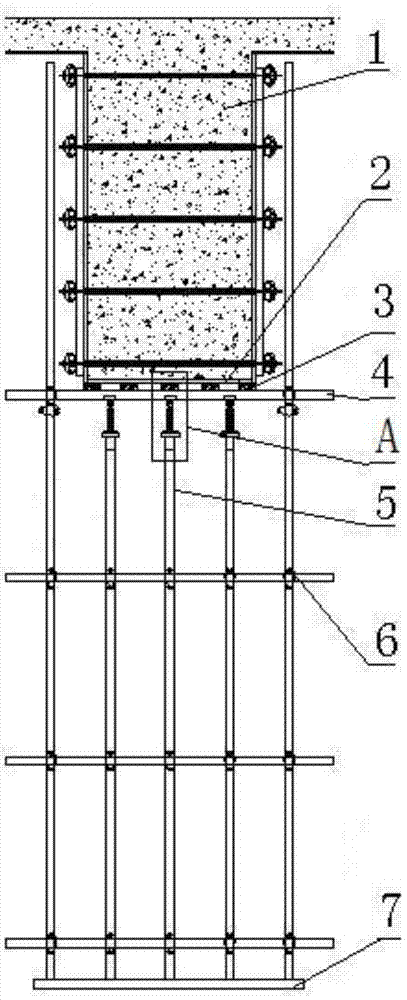

[0022] (2) Erect the scaffolding pole 5 and the scaffolding crossbar 4 and lock them with fasteners 6, fix the sweeping pole 7 at the lower end of the scaffolding pole, and determine the layout according to the calculated number of special support devices under the bottom mold of the assembled mass concrete beam The number of sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com