A water-retaining thickener with bentonite as the main raw material and its preparation method

A technology of water-retaining thickener and main raw material, which is applied in the field of water-retaining thickener and its preparation, can solve the problems such as the adverse effects of mortar strength and impermeability, and achieve the goal of improving layer segregation, reducing dosage, and requiring low precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

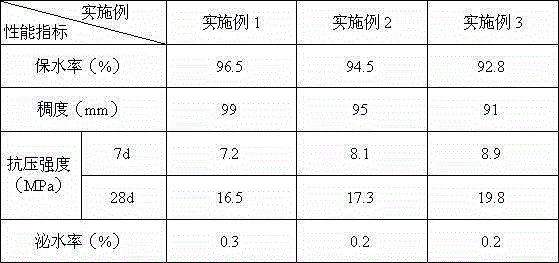

[0034] A water-retaining thickener with bentonite as the main raw material, which is formulated with bentonite 100, cellulose ether 1.10, starch ether 3.50, fly ash 33.0, thixotropic agent 1.0, and water reducer 6.00. Mix and stir according to the weight ratio of 42.5 grade ordinary Portland cement 16.8%, river sand 67.4%, a water-retaining thickener with bentonite as the main raw material 1%, and water 14.7%. The measured properties of the mortar are shown in Table 1.

Embodiment 2

[0036] A water-retaining thickener with bentonite as the main raw material, which is formulated with bentonite 100, cellulose ether 0.55, starch ether 2.50, fly ash 40.5, thixotropic agent 3.5, and water reducer 3.90. Mix and stir according to the weight ratio of 42.5 grade ordinary Portland cement 16.8%, river sand 67.4%, a water-retaining thickener with bentonite as the main raw material 1%, and water 14.7%. The measured properties of the mortar are shown in Table 1.

Embodiment 3

[0038] A water-retaining thickener with bentonite as the main raw material, which is formulated with 100 bentonite, 0.11 cellulose ether, 1.65 starch ether, 55.0 fly ash, 4.0 thixotropic agent, and 1.43 water reducer. Mix and stir according to the weight ratio of 42.5 grade ordinary Portland cement 16.8%, river sand 67.4%, a water-retaining thickener with bentonite as the main raw material 1%, and water 14.7%. The measured properties of the mortar are shown in Table 1.

[0039] Table 1 embodiment mortar performance test result

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com