Emulsion pump device

An emulsion pump and pump rod technology, applied in the field of emulsion pump devices, can solve the problems of high production cost, slow pumping, complex structure, etc., and achieve the effects of low production cost, stable ejection volume and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

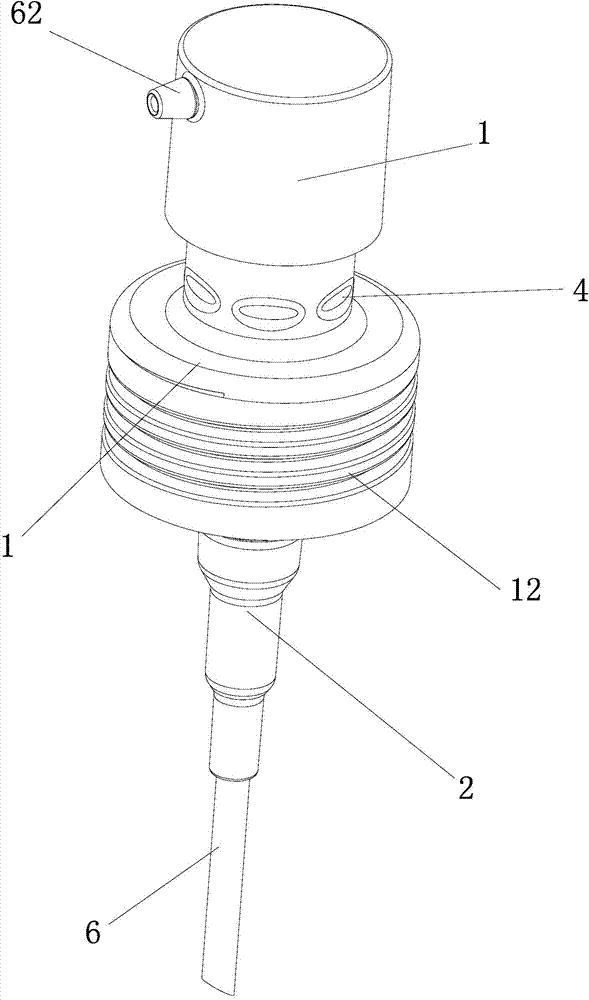

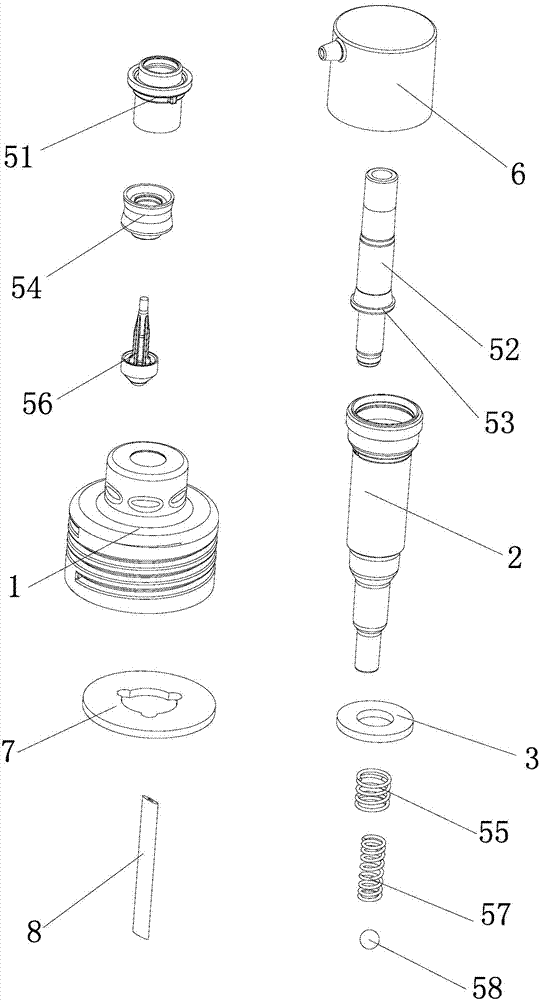

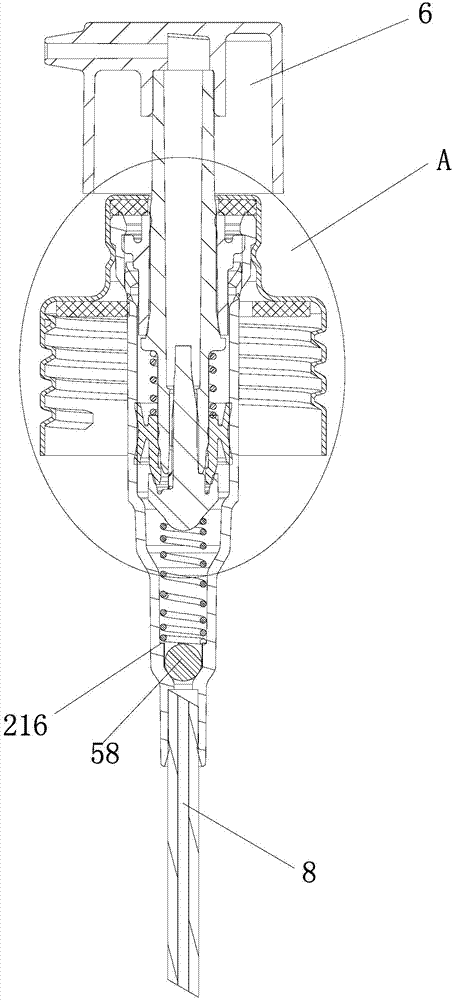

[0028] Such as Figures 1 to 8 The shown a lotion pump device includes a sealing cup 1, and the sealing cup 1 includes a sealing cup seat 11, on the outer wall of the sealing cup seat 11, a screw thread 12 connected with the bottle body is provided. The cup sealing seat 11 is provided with a convex connecting portion 13, and a mounting hole 14 is arranged on the convex connecting portion 13, a pump chamber 2 is arranged in the mounting hole 14, and a pump chamber 2 is arranged on the outer wall of the upper end of the pump chamber 2. The limited convex ring 21 is provided with an inner gasket 3 between the upper end surface of the pump chamber 2 and the inner wall of the convex connection part 13, and a plurality of gaskets are evenly distributed on the convex connection part 13 to make the pump chamber 2 tight. Connected to the inner co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com