Auxiliary device for precision argon arc welding of an elastic clamping ring and welding method thereof

An elastic collar and auxiliary device technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor welding quality, restricting engine matching delivery, and narrow structure size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

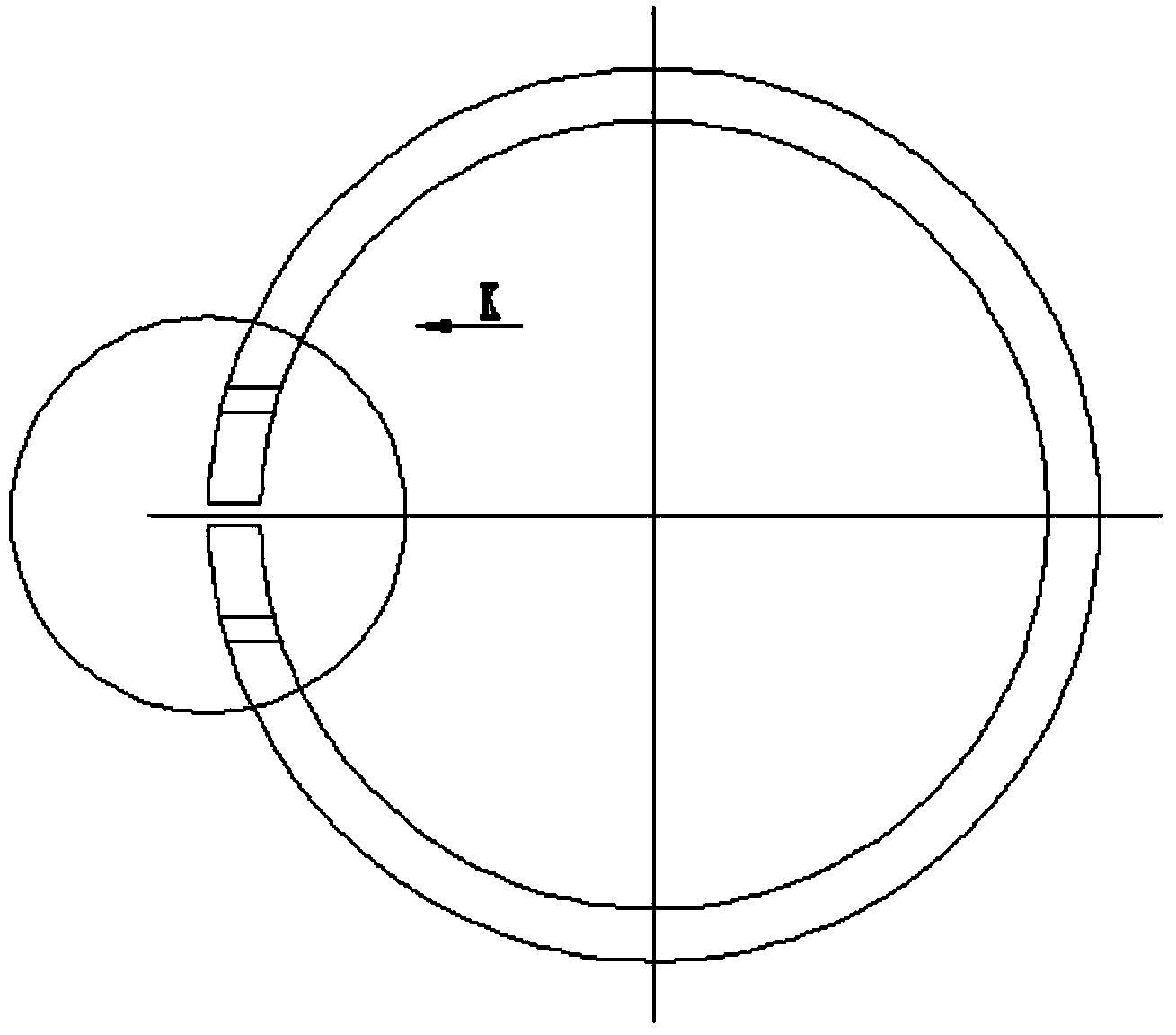

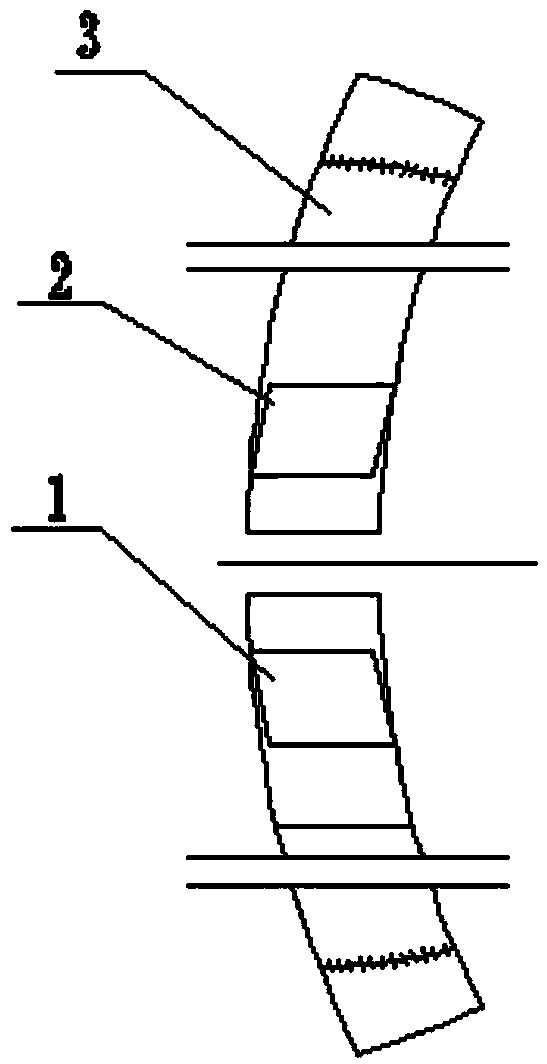

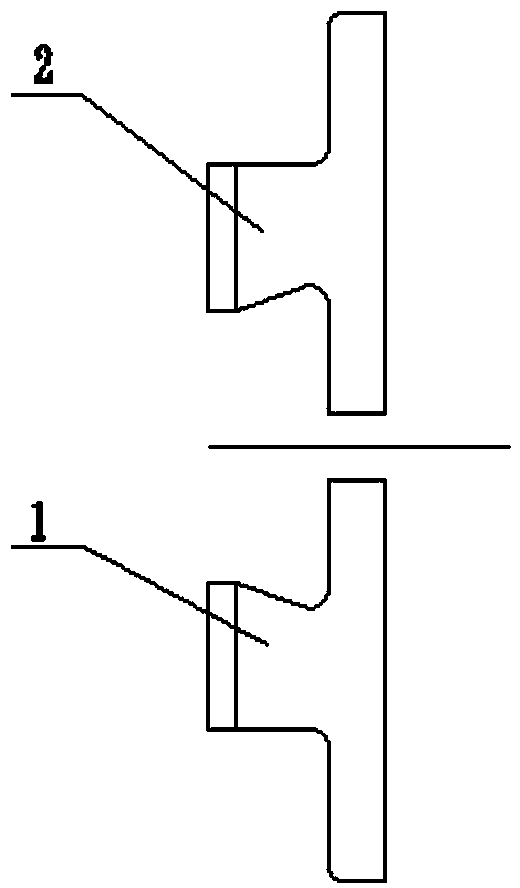

[0021] Such as figure 1 The elastic collar shown, including the figure 2 or image 3 As shown in the left collar head 1, right collar head 2 and elastic collar body 3, before welding, the parts to be welded of the elastic collar body 3, left collar head 1 and right collar head 2 and Figure 4 The surfaces of the shown arc starting plate 4 and arc terminating plate 5 are polished to a metallic luster, the material is not allowed to be thinned, and dirt is removed; then as Figure 5 As shown, the elastic collar main body 3 is assembled in the positioning ring 6, and the right collar head 1 and the left collar head 2 are assembled in the collar groove 95 of the upper pad 97 in the spacer 9, as Figure 6 As shown, the spacer 9 is a "long ring gas lens type rectification mechanism", and the spacer 9 includes an upper spacer 97 and a lower spacer 99, and the upper spacer 97 is placed on the lower spacer 99, and the elastic collar The spacer 9 at the welding seam is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com