IGBT drive circuit, and electromagnetic induction heating device and method

A driving circuit and current technology, applied in the field of IGBT driving circuit and electromagnetic induction heating equipment, can solve the problems of large short-circuit current, burning out IGBT, IGBT service life influence, etc., to improve service life, ensure normal operation, and effectively protect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

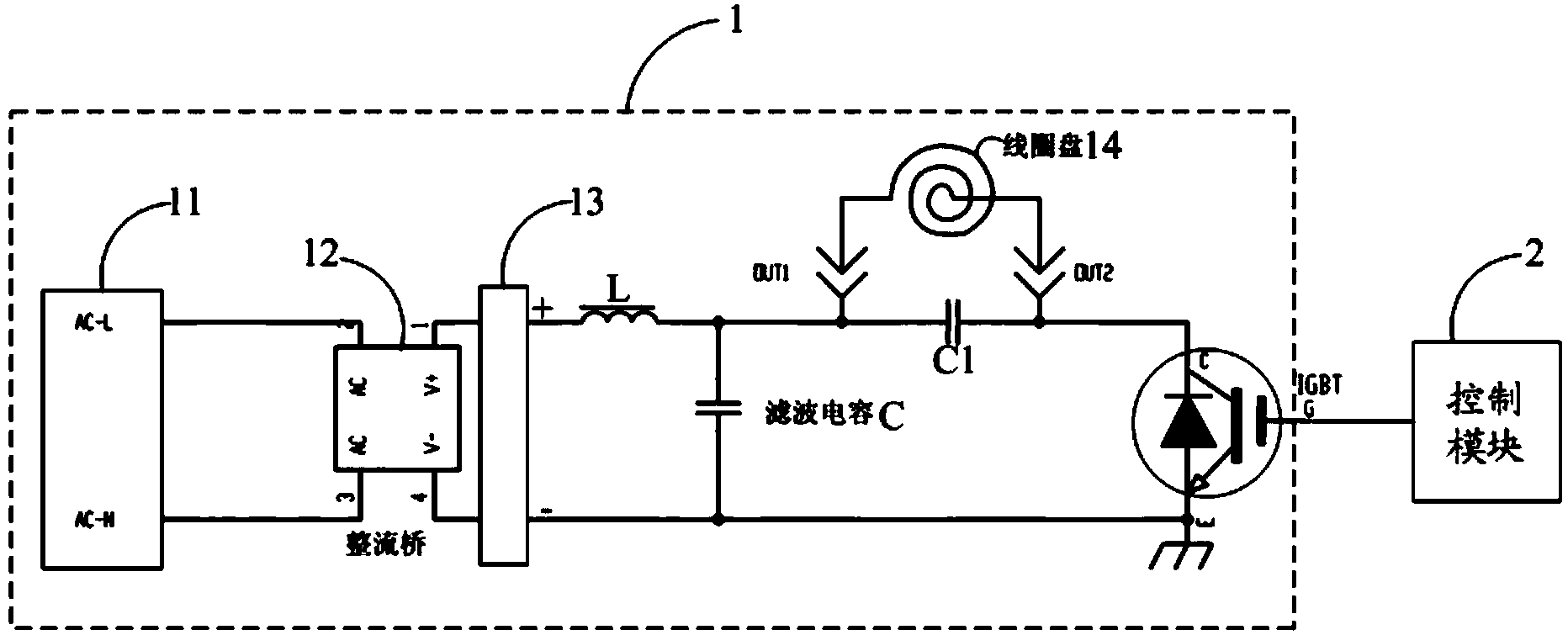

[0026] The working principle of the IGBT drive circuit of the preferred embodiment of the present invention is specifically described as follows:

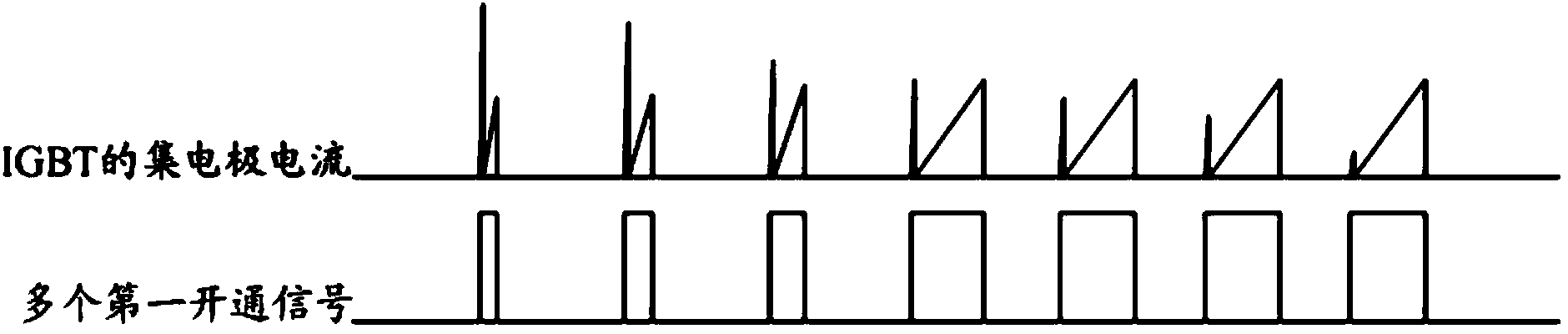

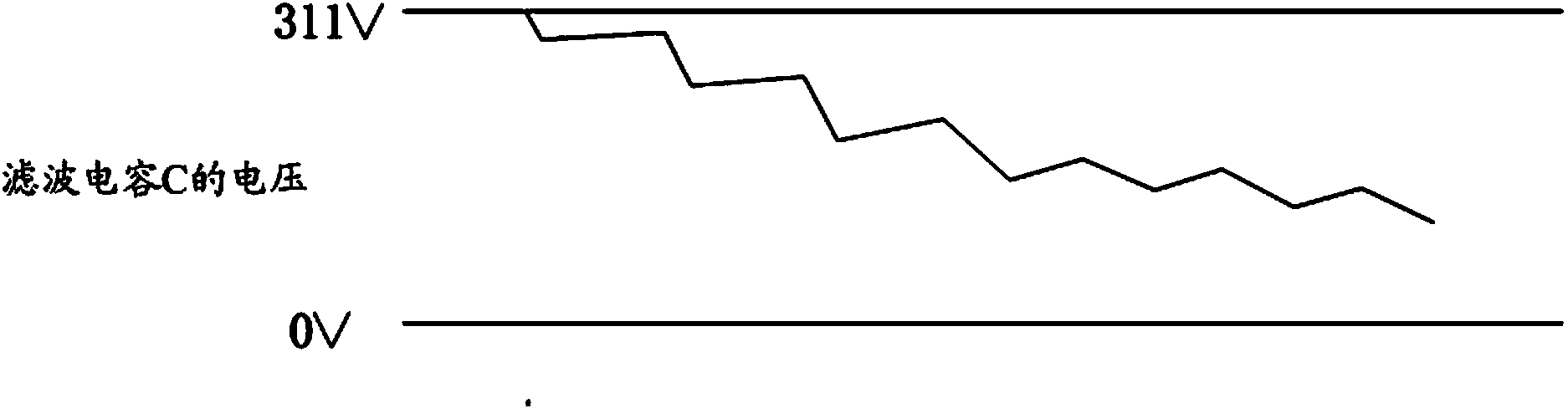

[0027] refer to figure 2 and image 3 shown, figure 2 is the corresponding schematic diagram of the magnitude of the collector current of the IGBT and the plurality of first turn-on signals in the IGBT drive circuit of the preferred embodiment of the present invention; image 3 It is a schematic diagram of the voltage change on the filter capacitor C in the IGBT drive circuit according to the preferred embodiment of the present invention.

[0028] In this embodiment, before the IGBT is turned on, the DC power input through the DC input terminal 13 charges the filter capacitor C, the voltage across the filter capacitor C increases continuously, and the control module 2 outputs a plurality of first turn-on signals to the IGBT at intervals, Since the turn-on times of the plurality of first turn-on signals are arranged in ascendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com