Method for calculating straightening force of roller type straightening machine through multi-pole boundary element method

A technology of boundary element method and straightening machine, which is applied in calculation, special data processing applications, instruments, etc., can solve problems such as the influence of straightening effect, the influence of straightening force model establishment, and unsatisfactory finite element calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] This embodiment is used to illustrate the invention, but not to limit the invention in any way.

[0117] The experimental verification is carried out on the experimental platform of the 11-roll leveler in the laboratory. Q235 steel is selected as the straightening piece material. The straightening piece has a thickness of 40mm, a width of 600mm, an elastic modulus of 2.06E+11, a Poisson’s ratio of 0.3, and an inlet and outlet bending amount of -2.08mm / 0mm. The theoretically calculated straightening force is 1921.67KN, the measured straightening force is 1969.47KN, and the error between the measured straightening force and the calculated value is 2.49%.

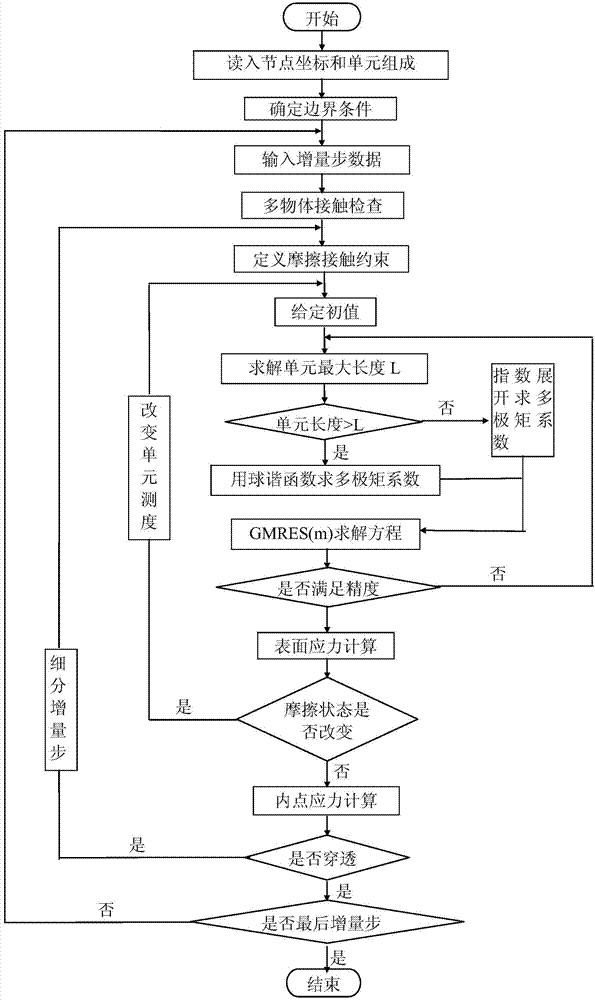

[0118] The process is as follows:

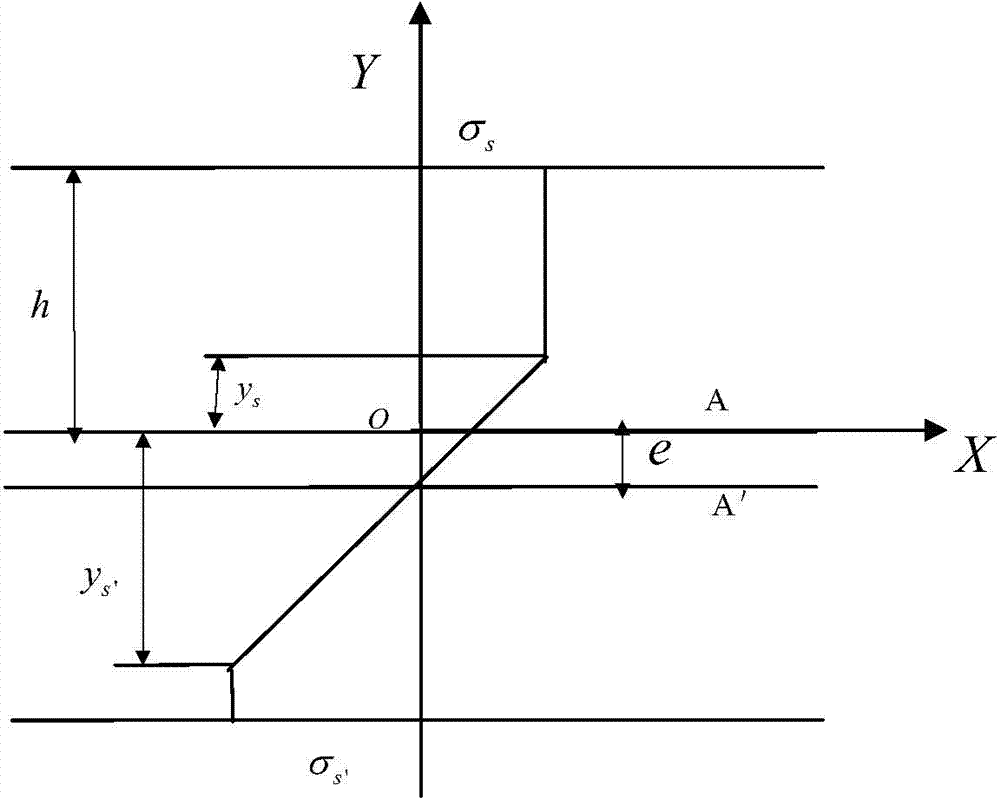

[0119] (1) According to the product specification, use the formula (1) to obtain the offset of the neutral layer as 0.215mm, and calculate the straightening force calculation formula F including the offset of the neutral layer according to the formula (2) 1 1466.4KN;

[0120] (2) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com