A Numerical Simulation Method for Analyzing the Structural Dimensions of Extrusion Dies with Unequal Lengths

A numerical simulation and structural size technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that the influence of metal rheology and temperature change behavior of unequal length working belts cannot be accurately obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

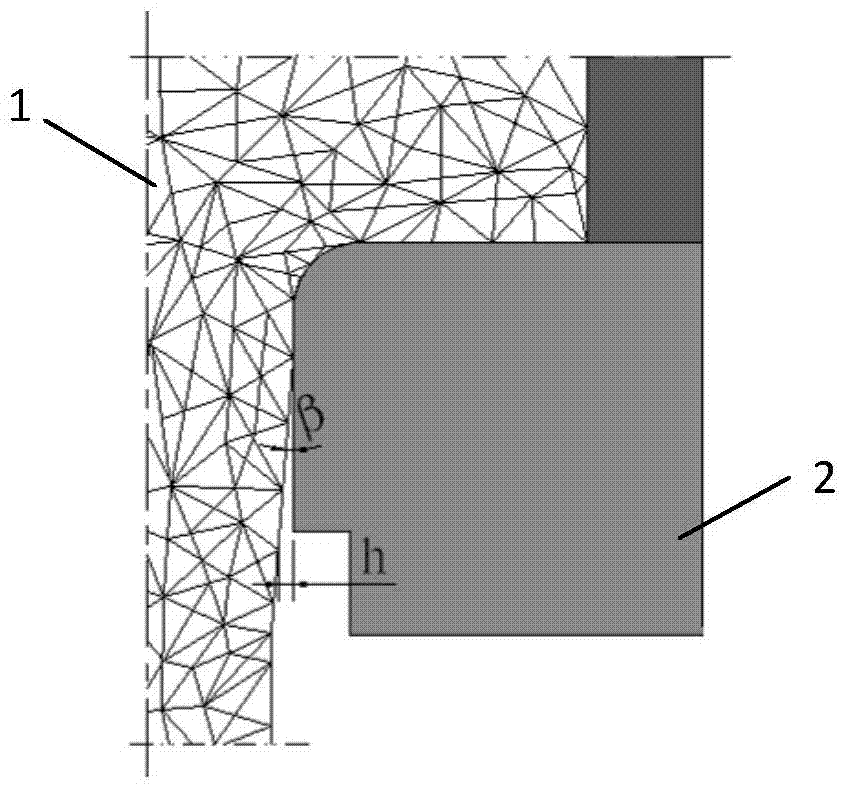

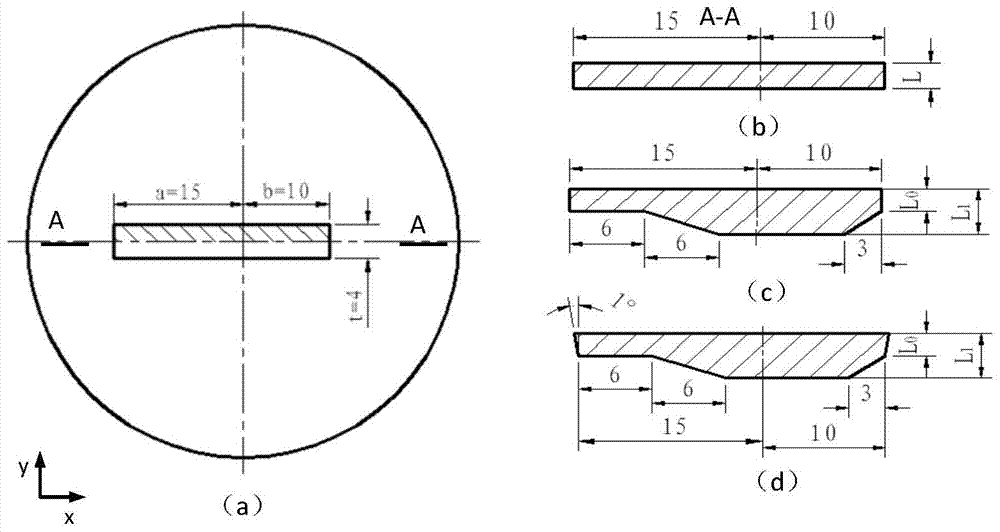

[0035] According to the above situation, in order to facilitate the judgment of the rationality of the simulation results and improve the calculation efficiency, the present invention first takes a small-section rectangular profile with a width of 25mm and a thickness of 4mm as an example, and solves the extrusion of the equal-length working belt by using unequal-length working belts. The knife-bent defects produced by the profile in the process, and then analyze the rationality of the calculation method. In order to obtain the knife bend produced during the extrusion of the equal-length working belt, the position of the die hole along the width direction (x-axis direction) is asymmetric to the center of the extrusion cylinder, such as figure 2 shown. When the working belt with equal length is used, since the metal flow rate near the center of the extrusion cylinder is fast, a knife bend on the left side will inevitably occur during extrusion. In order to eliminate the knife ...

Embodiment 2

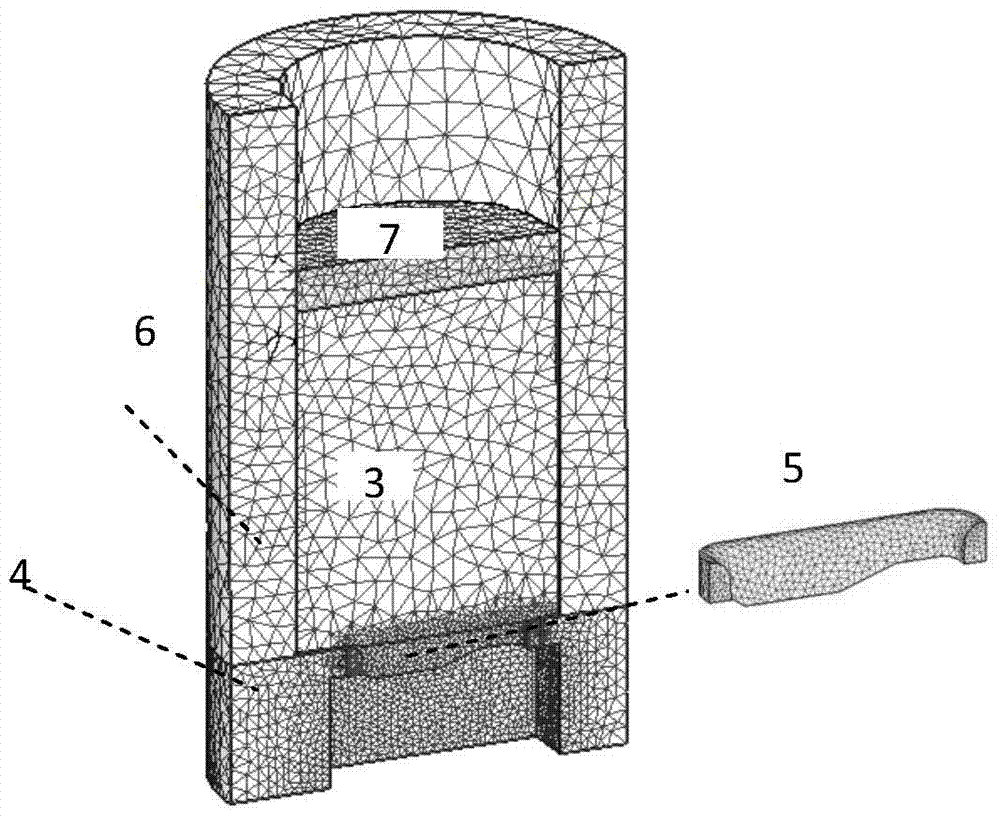

[0052] The rational configuration of the structural dimensions of the unequal-length working belt of the large-scale aluminum alloy solid profile extrusion die is the key to obtaining high surface quality, high dimensional precision products and improving the service life of the die. Figure 5 Shown is the cross-sectional shape and main dimensions of large aluminum alloy profiles, of which the cross-sectional area is 31303.9mm 2 .

[0053] according to Figure 5 It can be seen that the wall thickness of the profile varies greatly, and the wall thickness part (B) is located near the center of the extrusion barrel, while the thin wall parts (A, C, D) are far away from the center of the extrusion barrel. According to the extrusion theory, there is no friction between the metal at the center of the extrusion cylinder and the cylinder wall, and the metal flows most easily during the extrusion process, while the metal near the cylinder wall lags behind the flow of the metal relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com