Printing plate quality detection system and method

A quality detection method and detection system technology, applied in the field of printing plate quality detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described below in conjunction with the accompanying drawings.

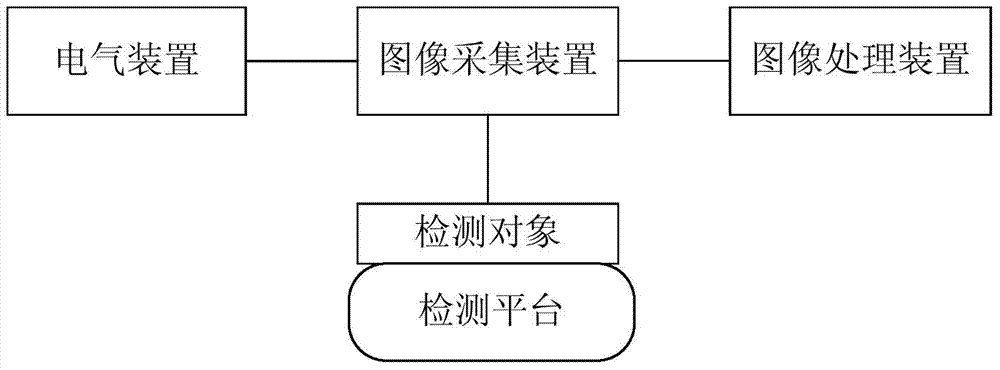

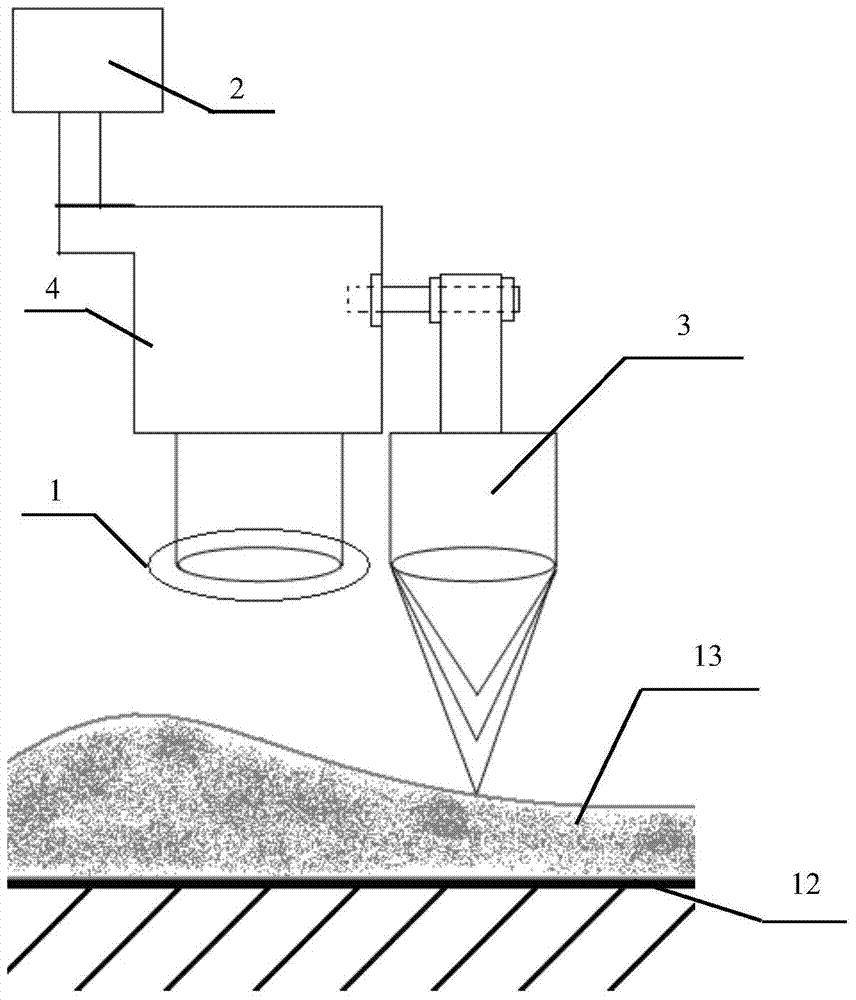

[0064] The invention relates to a printing plate quality detection system, which is used to detect the imaging quality of printing plates, gravure printing plates, films, printed products, etc. The structural diagram of the system is as follows figure 1 As shown, it includes a detection platform, an electrical device, an image acquisition device and an image processing device, wherein the image acquisition device is arranged above the detection platform and moves within the full-plate range of the printing plate driven by the electrical device. quality image, the image acquisition device includes an annular optical imaging light source, an area array camera and a laser displacement sensor, and the image acquisition device is driven to move horizontally and vertically by setting guide rails. Uniform illumination in the interior; under the illumination of the annular optical ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com