Cargo oil pump and turbine mounting and aligning method

A technology for turbine installation and cargo oil pump, which is applied to measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of errors, high precision required for equipment shaft calibration, and difficulty in alignment work, and achieves low production costs, Improve the accuracy of equipment installation and the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

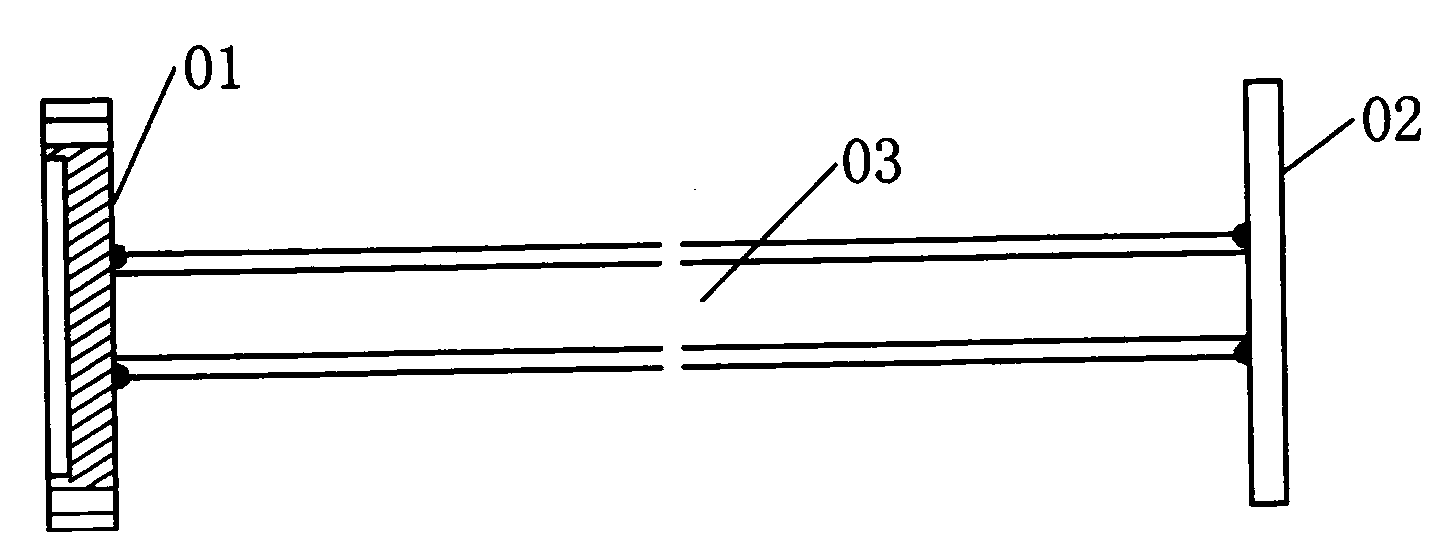

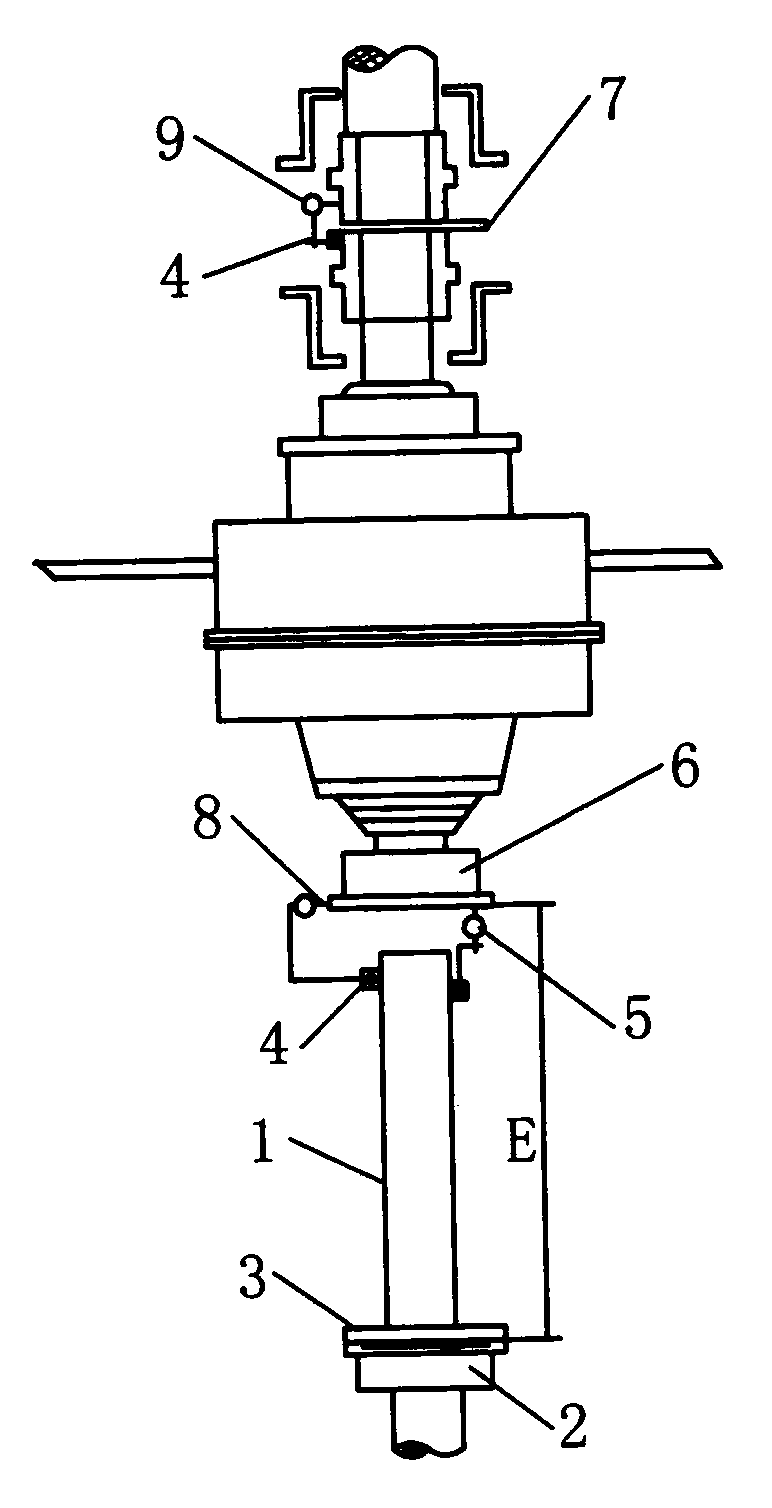

[0027] Make temporary shaft tooling: Consider the weight and use strength of the tooling, and the machining accuracy of the flange to ensure that the tooling is easy to use and easy to install. The temporary shaft flange can be connected with the output shaft flange of the cargo oil pump for zero-to-zero alignment. The segmental hoisting of the engine room and the pump room is completed, and the segmental hoisting of the tail area general group is completed.

[0028] 1. Positioning of the cargo oil pump: According to the layout position of the cargo oil pump installation drawing, draw a line on the double bottom of the pump room to determine the center position of the base of the cargo oil pump. Measure the height distance from the centerline of the cargo oil pump suction inlet flange to the inner bottom of the pump room. Check whether the distance between the base panel of the cargo oil pump and the base panel meets the installation requirements, and adjust the level of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com