Movable type tunnel kiln isolating device

A tunnel kiln and mobile technology, which is applied to the equipment accessories for brick firing, and the devices that block the flow of hot air in each functional section, can solve the problems of large disturbance, poor reel rigidity, and poor rolling effect. The effect of overcoming too much load and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

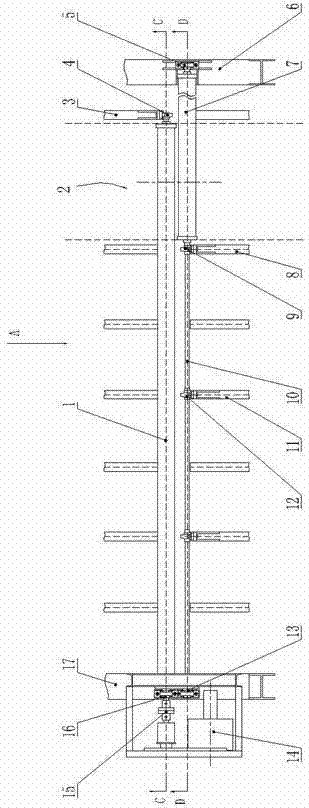

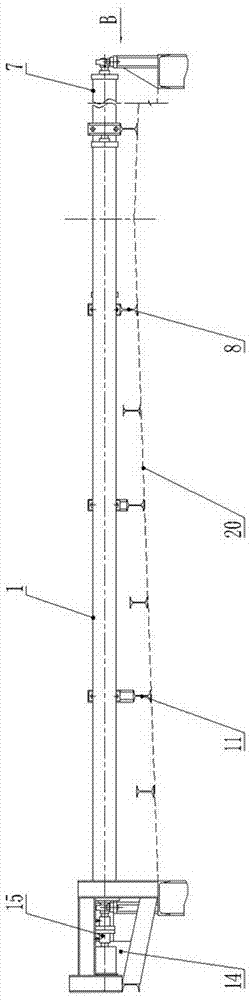

[0016] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] The traditional partition device uses a single reel to retract and unwind the heat-resistant cord, which easily affects the normal operation of the equipment. Aiming at this problem, the present invention proposes a partition device for double-drum retractable heat-resistant cord, such as Figure 1~5 As shown, the partition device includes a first reel 7 and a second reel 1 on the same horizontal plane and parallel to each other. In order to avoid mutual interference between the first reel 7 and the second reel 1, the distance between the two should be set appropriately. After the heat-resistant curtains arranged on the first reel 7 and the second reel 1 are put down, a complete partition surface can be formed. The heat-resistant cord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com