Holding frame

A cage and ring sleeve technology, applied in the cage field, can solve the problems of low cage production efficiency, short bearing service life, low working reliability, etc., and achieve the effects of easy use and promotion, prolonging service life, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

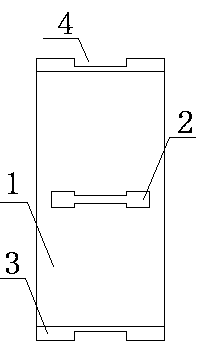

[0009] Such as figure 1 It is a schematic diagram of the structure of the present invention, a cage, including a ring sleeve 1, a needle hole 2, a connecting ring 3 and a groove 4, the ring sleeve 1 is provided with a needle hole 2, and the outside of the ring sleeve 1 is connected to the The connecting ring 3 is connected, and the connecting ring 3 is provided with a groove 4 .

[0010] When in use, the ring sleeve 1 is provided with a needle hole 2 along the circumference, and the outside of the ring sleeve 1 is fixedly connected with the connection ring 3, and the connection ring 3 is provided with a groove 4. This kind of cage has a simple, compact and reasonable structure, convenient and fast assembly, reliable connection, can increase the amount of grease stored, the bearing can be fully lubricated, improves the production efficiency of the cage, prolongs the service life of the bearing, and greatly improves the bearing capacity. The reliability of the bearing work is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com