Full coal roadway safe and speedy drivage supporting method

An all-coal roadway, safe technology, applied in the direction of earthwork drilling, bolt installation, mining equipment, etc., can solve the problems of not being able to effectively control the deformation of surrounding rock, affecting the speed of excavation, wasting support materials, etc., and achieve the effect of cutting coal , saving demolition time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

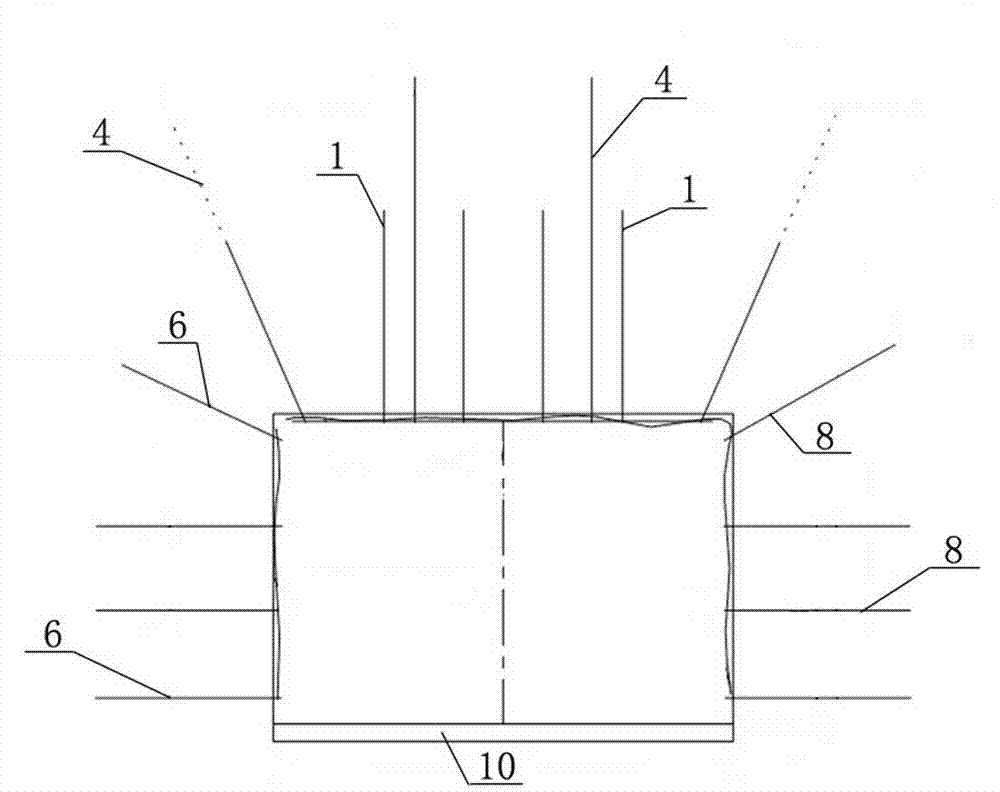

[0023] Such as figure 1 As shown, a safe and rapid excavation support method for an all-coal roadway, including the support for the roadway roof and the two sides of the roadway;

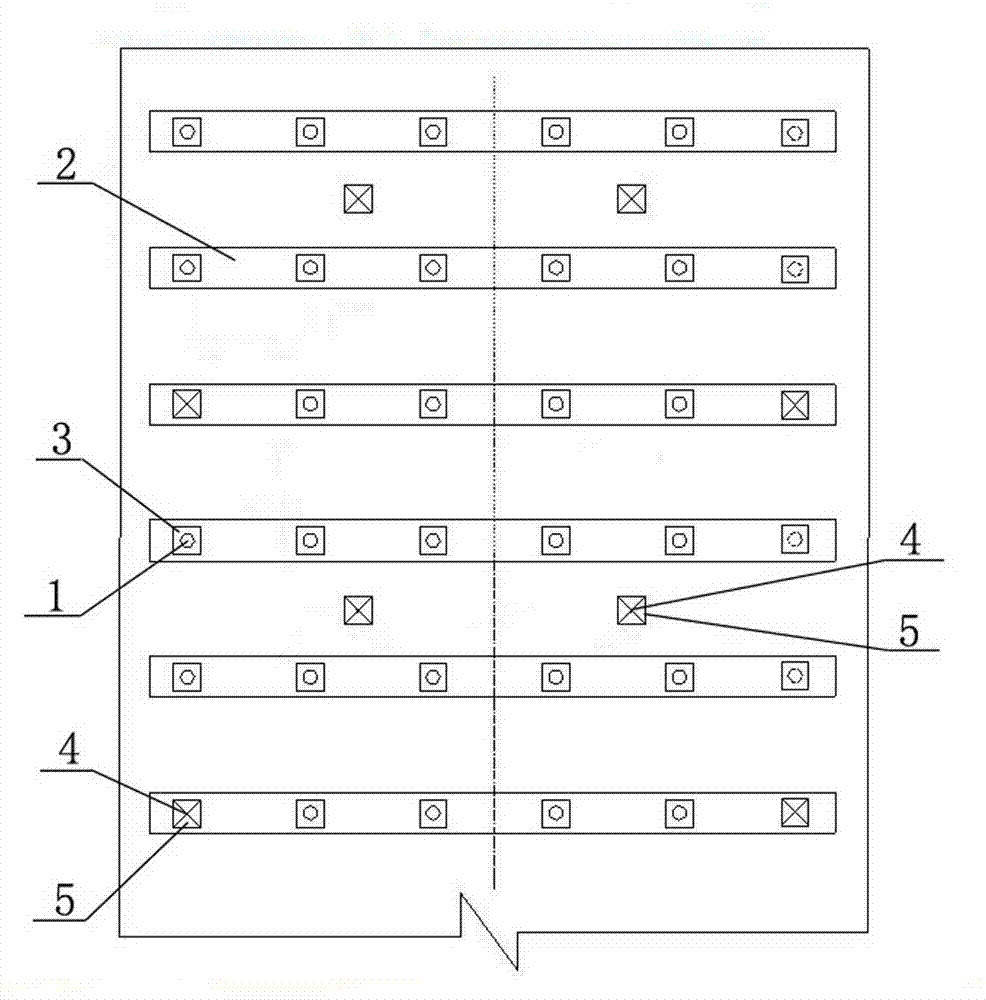

[0024] (1) Support of roadway roof

[0025] Such as figure 2 As shown, several rows of bolt rows are uniformly fixed on the roof of the roadway, and the distance between two adjacent rows of bolt rows is 1000mm; each row of bolt rows includes several 20MnSi left-handed threads without longitudinal reinforcement with a diameter of 22mm and a length of 2400mm. Steel anchor rods 1, the distance between two adjacent 20MnSi left-handed threaded steel anchor rods 1 without longitudinal reinforcement in the same row is 900mm, each 20MnSi left-handed threaded steel anchor rod 1 without longitudinal reinforcement in each row of anchor rods is connected with the roadway roof Vertically fixed, 20MnSi le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com