Full Face Shaft Drilling Rig

A full-section, drilling rig technology, applied in shaft equipment, sinking, earthwork drilling, etc., can solve problems such as difficulty in automation of sinking equipment, difficulty in increasing the speed of shaft excavation, and failure to achieve major breakthroughs, so as to shorten the construction of wells cycle, easy to operate and use, and a high degree of mechanical automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

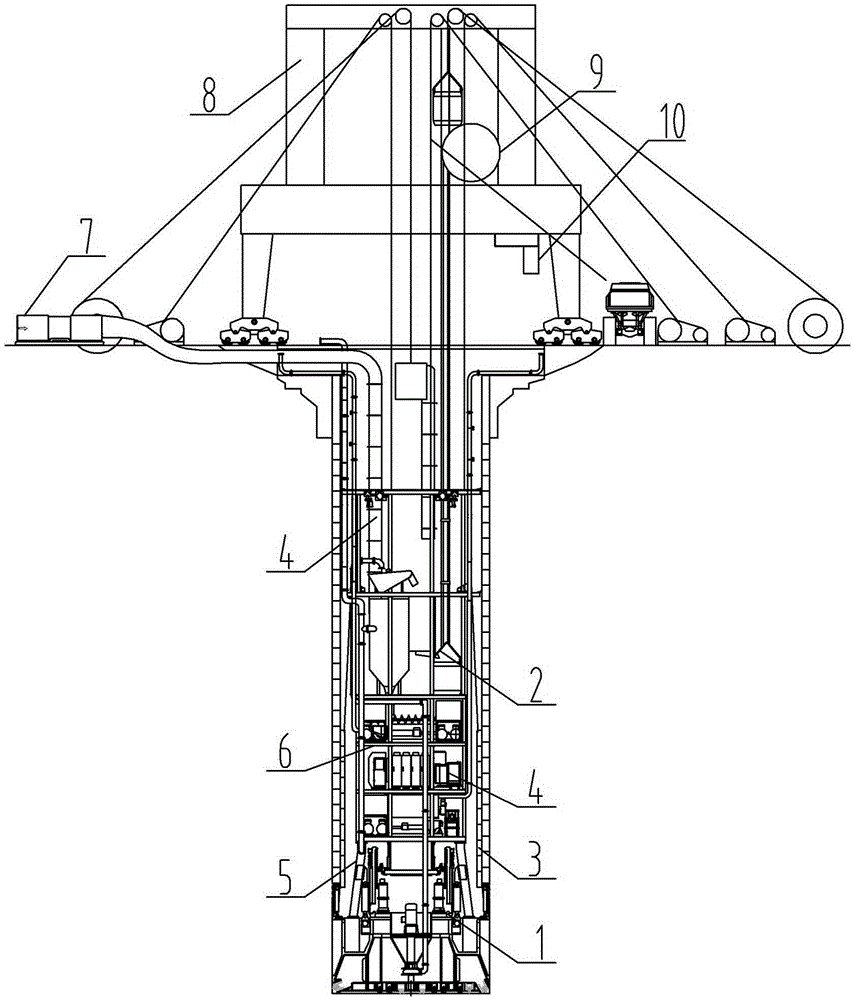

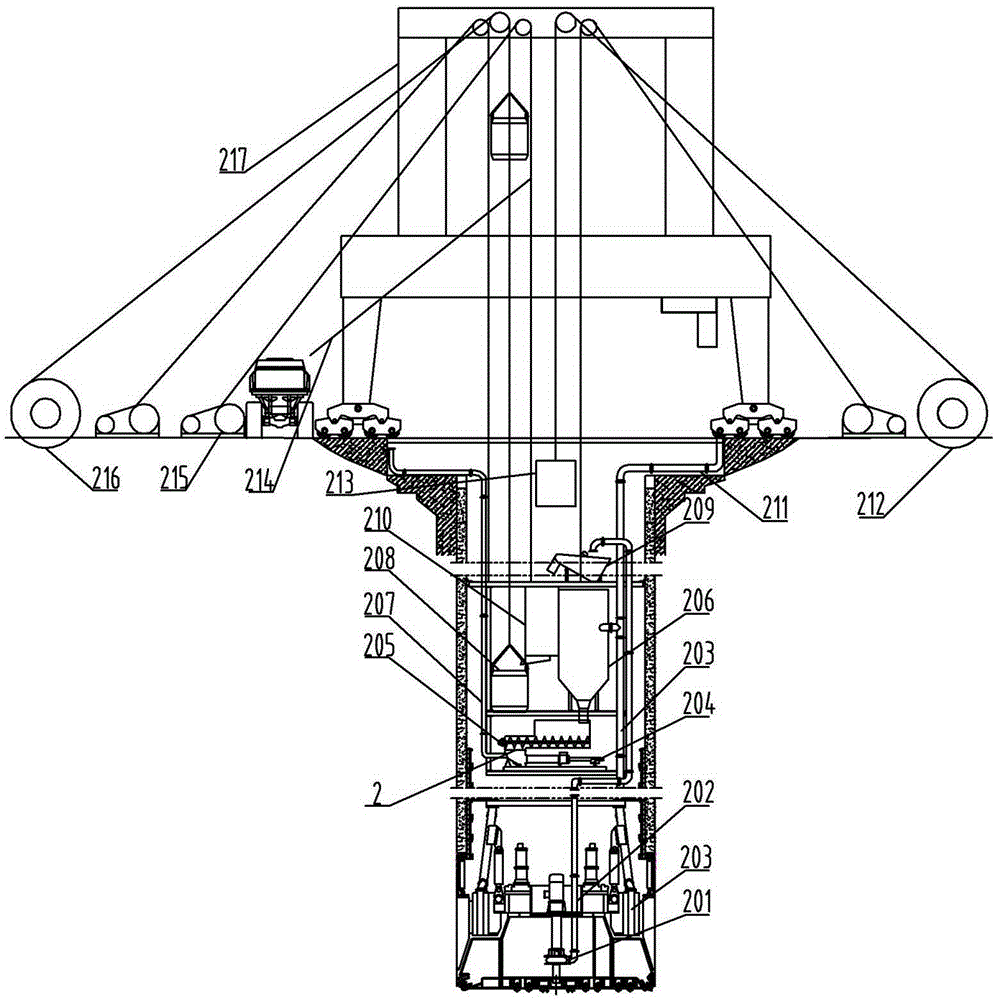

[0034] see Figure 1 to Figure 8 , in the figure, the full-section vertical shaft drilling rig of the present invention is divided into four major systems and equipment main beam 5, equipment platform 6, fan 7. Derrick 8, cable drum 9, control room 10, etc. Each system is composed of independent equipment.

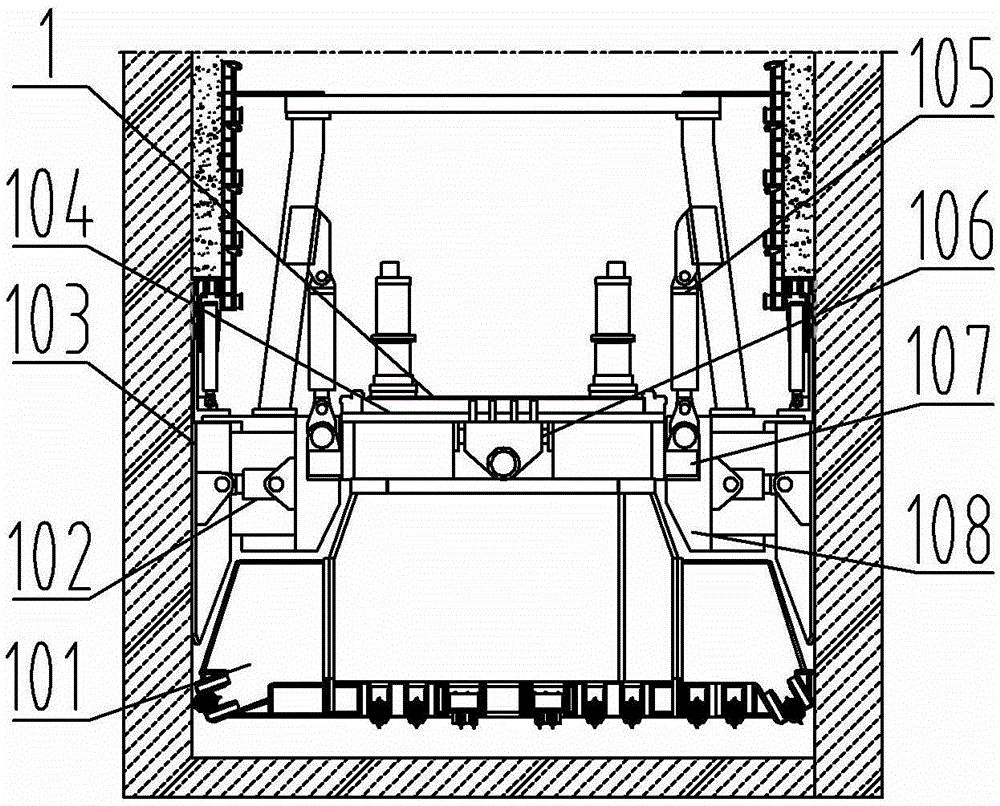

[0035] The shaft excavation system is mainly composed of a cutter head 101, a shoe cylinder 102, a shoe 103, a main drive 104, a propulsion cylinder 105, a steering knuckle 106, a cross shaft 107, and a shoe fixed ring 108. There are multiple stretchers and form an annular structure, and each stretcher is connected to the main drive through a sliding key. The stretcher cylinder 102 tightens the stretcher 103 and acts on the well wall to generate the force point of the propulsion cylinder 105. The propulsion cylinder pushes 105 to push the main drive 104 and then pushes the cutterhead 101 to generate excavation action. The cutterhead 101 is controlled by controlling the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com