Gate-pier fair-faced concrete one-off forming construction method

A fair-faced concrete and concrete technology, which is applied in basic structural engineering, construction, etc., can solve problems such as surface roughness, and achieve the effect of consistent color, high structural strength and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

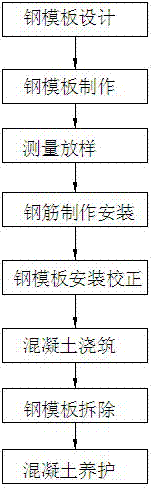

[0027] The present invention will be further described below in conjunction with the accompanying drawings:

[0028] refer to figure 1 As shown, in Example 1, a one-time forming construction method of fair-faced concrete for gate pier includes (1) steel formwork design:

[0029] a. Before the design of steel formwork, one should be fully familiar with the structural design drawings related to the formwork, clarify the structural quality requirements, understand the construction organization design of the project related to the erection of supports and the layout of vertical transportation equipment, etc. Preliminary determination of the maximum size and modulus of the template according to the storage and other conditions;

[0030] b. The design of steel formwork should follow the basic requirements of standardization and generalization, and at the same time, special design should be carried out for special structural parts such as gate corbels, gate slots, cantilevered platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com