Flow distributing facility of front water feeding pond of large circulating water pump station of power plant and construction method for flow distributing facility

A technology of circulating water pump and forecourt, used in pumping stations, water conservancy projects, water conservancy engineering equipment, etc., can solve the problems of increasing project investment and floor space, unsatisfactory rectification effect, affecting the safe operation of pumps, etc. Excellent effect, shortening the length of the front pool, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

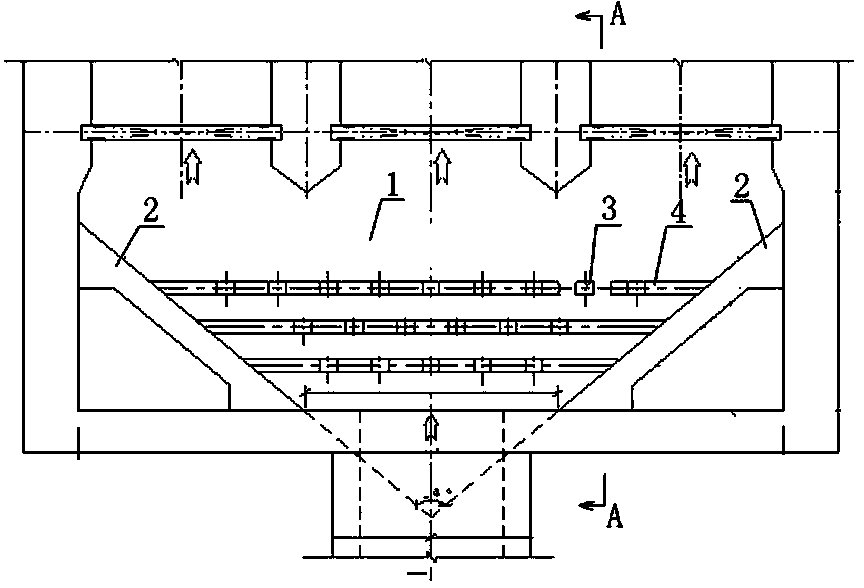

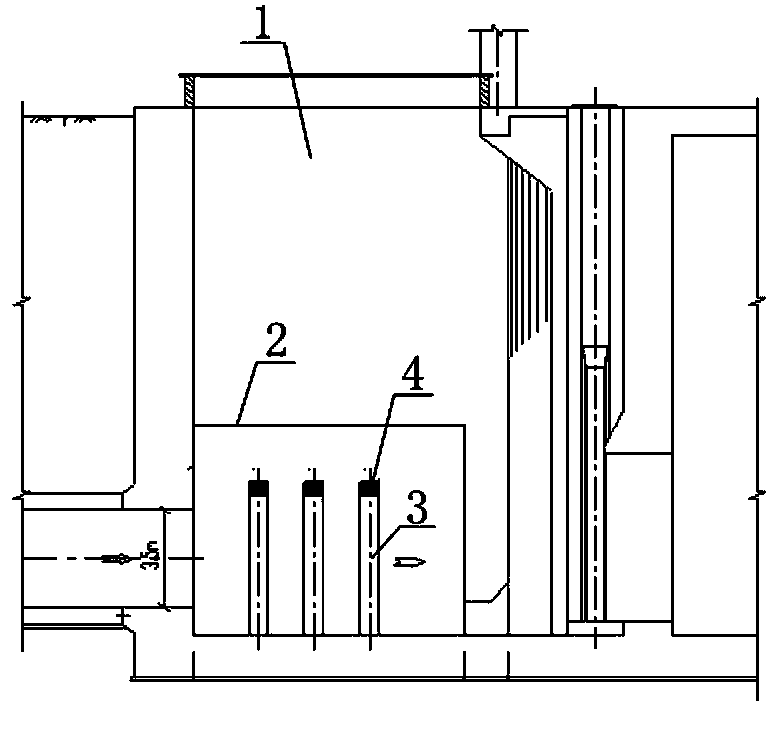

[0027] Embodiment: The present invention first determines the wing walls on both sides according to the width and depth of the water diversion tunnel (or open channel) of the pumping station and the water inlet forebay, and sets reinforced concrete rectifying square columns between the tunnel (or open channel) entrance and the wing walls on both sides Three rows, arranged in a plum blossom shape, the first row is 1.7-2.0m away from the entrance of the tunnel (or open channel), and the distance between each row is ~1.5m. The scale of water diversion and the size of the water inlet pool are changed to adjust the distance between columns and columns, and between rows; flush). In this way, the distance from the exit of the tunnel to the entrance of the flow path of the pumping station is 8.50m, and the total length of the underground structure of the pumping station is 45.90m.

[0028] The present invention firstly solves the problem of effective rectification of the inlet foreba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com