Novel papermaking felt

A paper-making blanket, a new technology, applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of decreased water permeability, shortened service life, easy deviation of the felt, etc., to prolong the service life, ensure normal operation, and dehydration capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

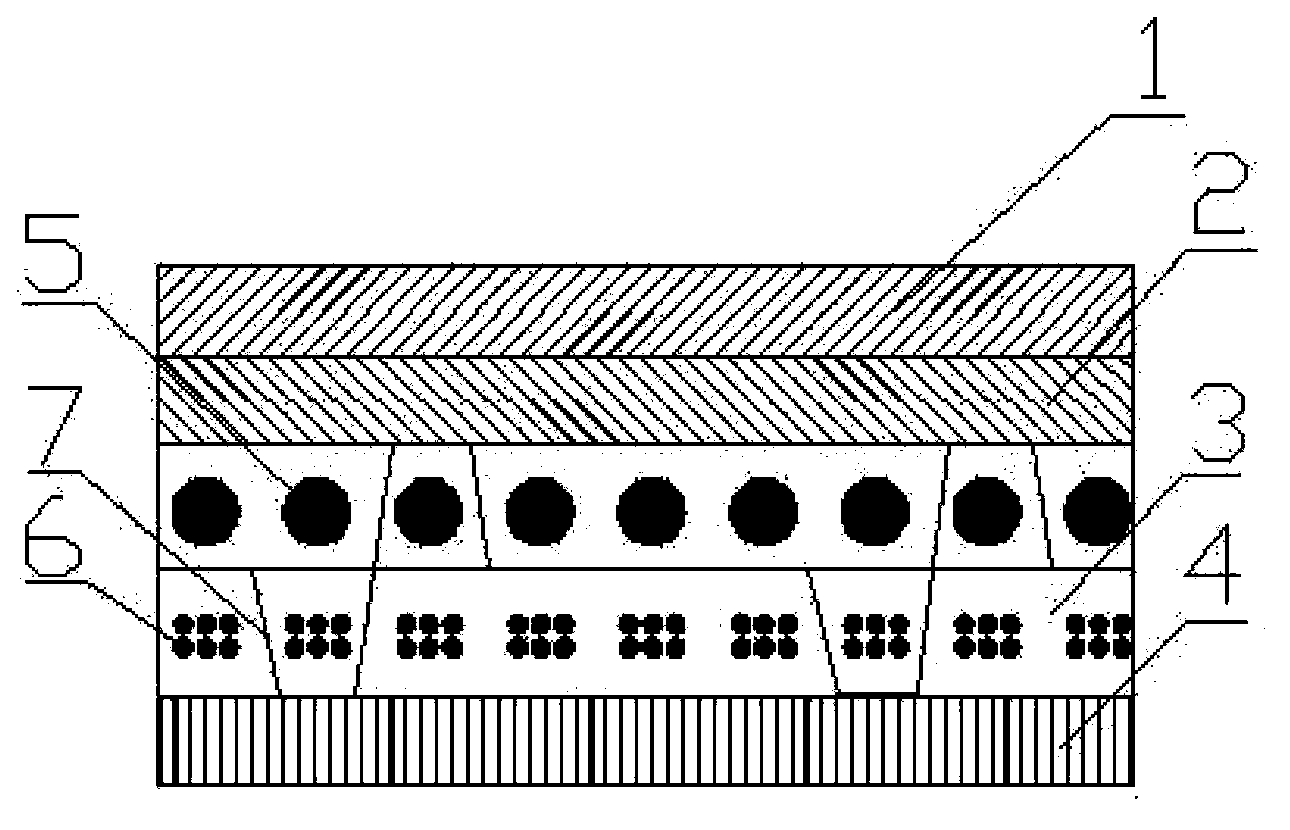

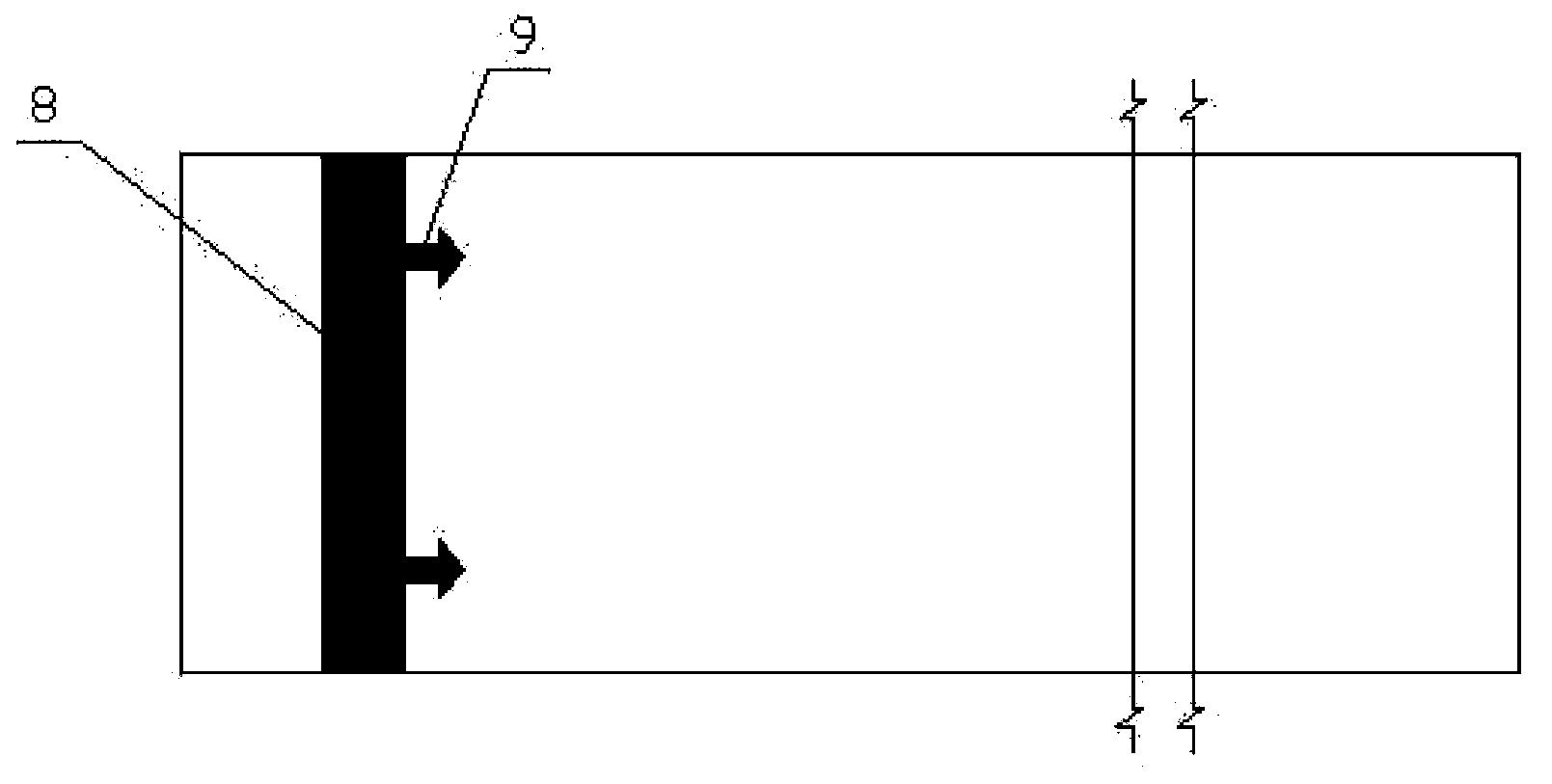

[0017] As shown in the figure: a new type of papermaking felt, which is composed of a fiber surface layer 1, a fiber core layer 2, a base cloth layer 3 and a fiber back layer 4 from top to bottom, and is characterized in that: the base cloth layer 3 and the fiber surface layer 1. The fiber core layer 2 and the fiber back layer 4 are all interwoven by needle punching. The base fabric layer 3 is composed of an overall thickened and reinforced strong fabric layer formed by interweaving warp threads and weft threads. The base fabric layer The upper warp thread 5 of the layer 3 is a wool-like yarn, the lower warp thread 6 is a nylon strand, and the weft thread 7 of the base fabric layer 3 is a nylon filament monofilament; the front of the new papermaking blanket is provided with a standard thread ribbon 8. The standard line ribbon 8 ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com