Son-mother trolley doffer six-connecting-rod guiding track abutting connection self-locking mechanism

A doffer and six-bar linkage technology, applied in textiles and papermaking, etc., can solve the problems of affecting productivity, cumbersome adjustment process, etc., and achieve the effects of low manufacturing and maintenance costs, small size, and simple mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and multiple embodiments.

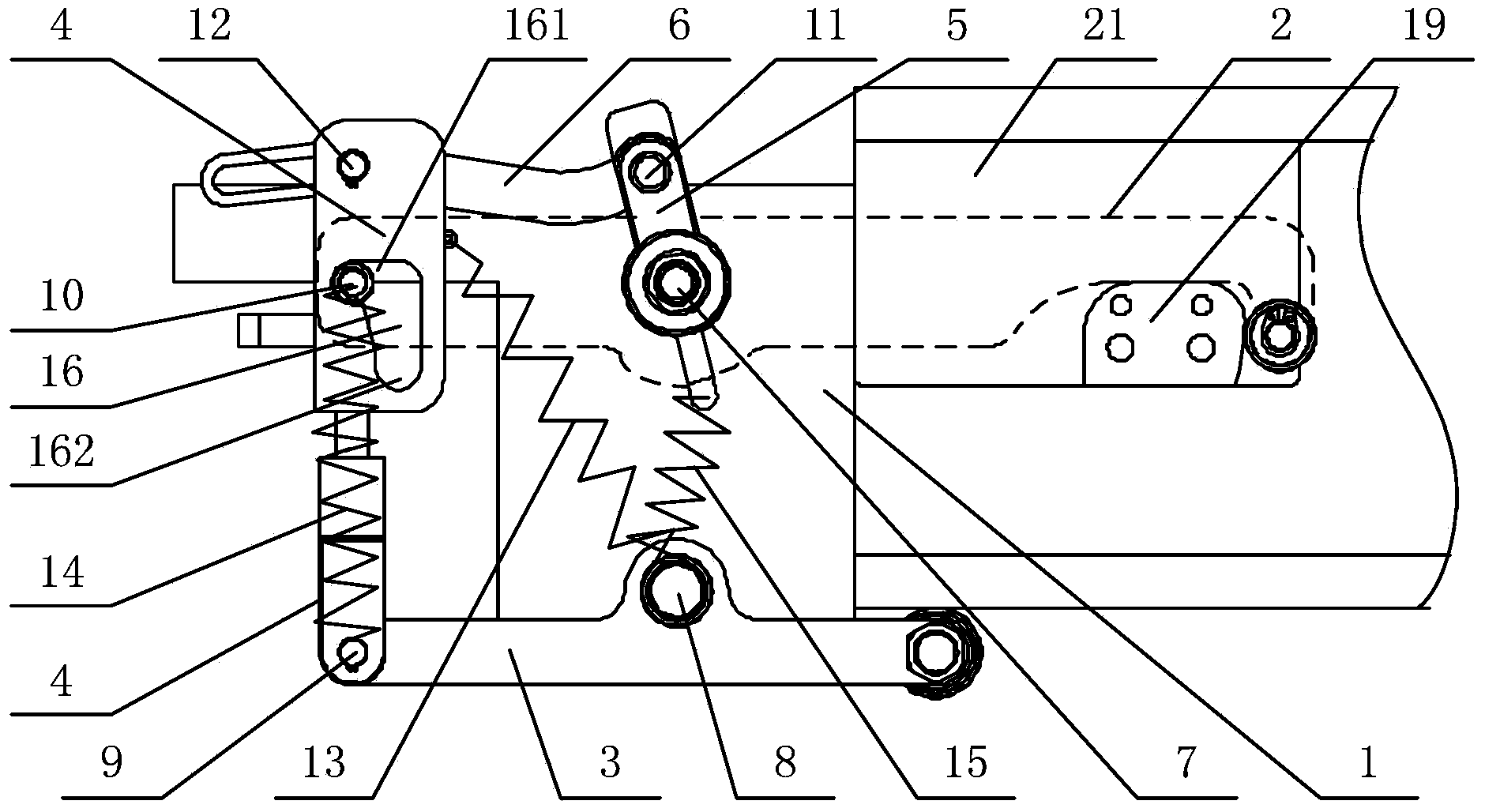

[0039] An embodiment of a six-link guide rail butt joint self-locking mechanism of a mother car doffing machine designed by the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10As shown, it includes a base 1, a first connecting rod 2, a second connecting rod 3, a third connecting rod 4, a swing rod 5, a shift rod 6, a first shaft 7, a second shaft 8, a third shaft 9, a Four shafts 10, the fifth shaft 11, the sixth shaft 12, the first spring part 13, the second spring part 14, the third spring part 15 and the protrusion 19; the middle part of the first connecting rod 2 passes through the first shaft 7 Hinged on the base 1, one end of the first connecting rod 2 is fixedly sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com