Microelectrolysis-fenton oxidizing reaction device

A Fenton oxidation and reaction device technology, which is applied in oxidation water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high operating cost, large construction investment, and difficulty in obtaining treatment efficiency, etc. To achieve the effect of improving the service life and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

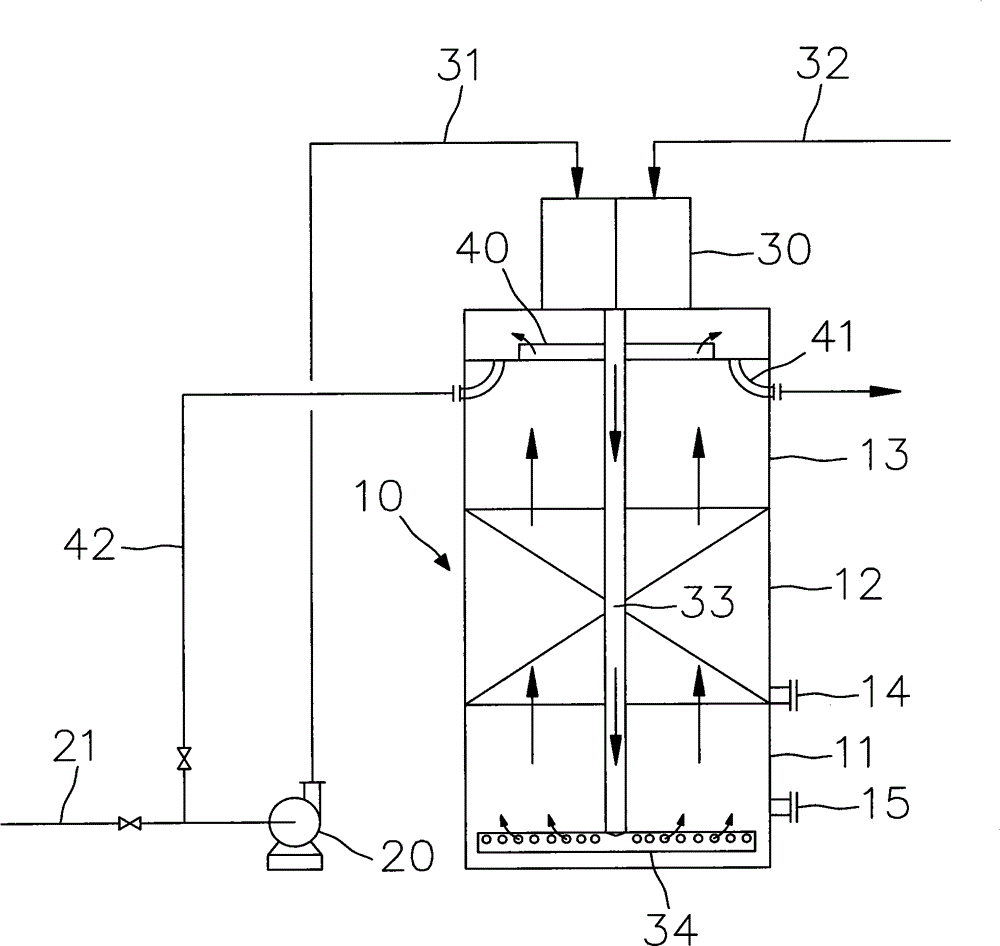

[0032] Such as figure 1 Shown, a kind of micro-electrolysis-Fenton oxidation reaction device is characterized in that this oxidation reaction device comprises the following components:

[0033] A waste water supply device for sending the waste water initially mixed with the Fenton reagent into the Fenton oxidation reaction zone 11 of the reactor 10;

[0034] Reactor 10, the reactor 10 is a hollow cylinder made of anti-corrosion material, the inside of the cylinder of the reactor 10 is divided into a Fenton oxidation reaction zone 11, a micro-electrolysis reaction zone 12 and a flocculation reaction zone from bottom to top 13. The Fenton oxidation reaction zone 11 and the micro-electrolysis reaction zone 12 and the micro-electrolysis reaction zone 12 and the flocculation reaction zone 13 are connected to each other, and the micro-electrolysis reaction zone 12 is covered with iron-carbon fillers;

[0035] A drainage device, the drainage device is arranged on the upper side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com