Winding-machine control method based on stable tensile force

A control method and winding machine technology, which is applied in thin material processing, conveying filamentous materials, transportation and packaging, etc., can solve the problems of not easy tension fluctuation, tension fluctuation, and low real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. Start the optimal control of the take-up speed.

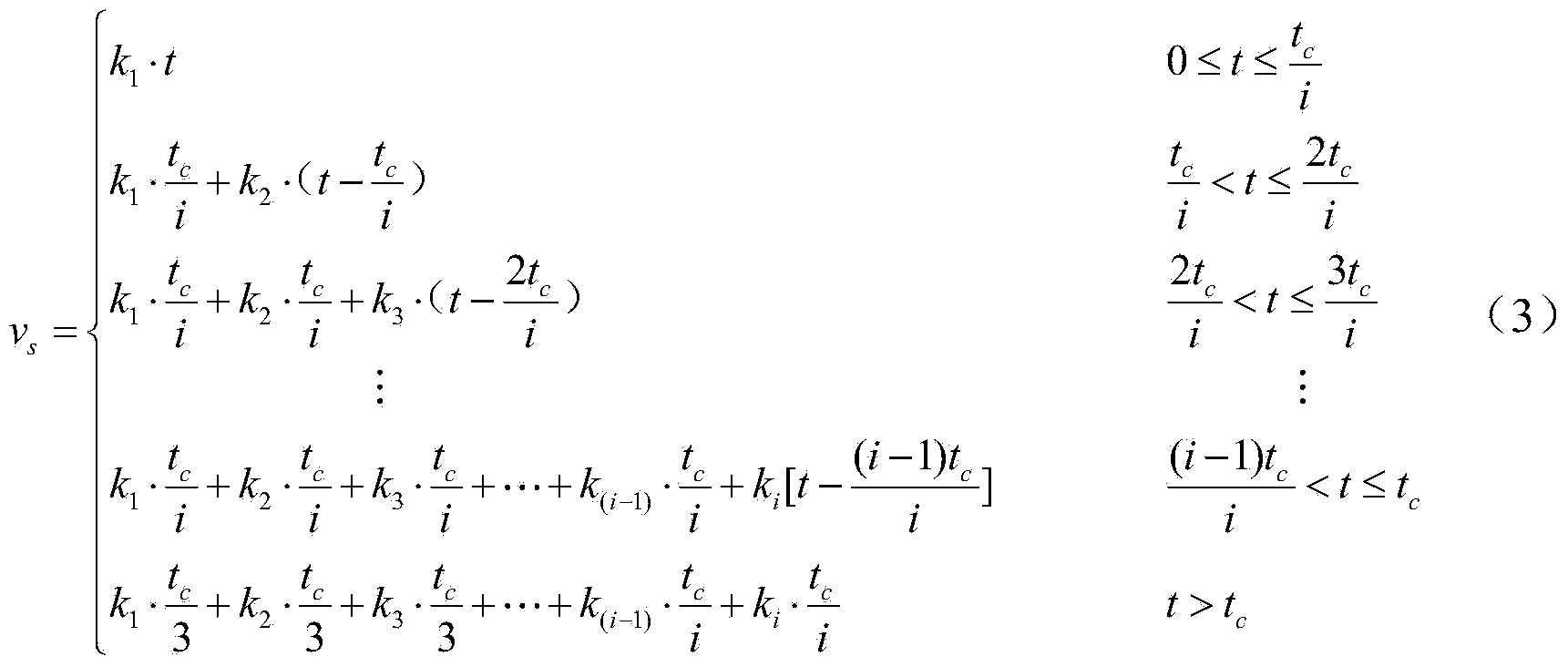

[0025] The change of the line acceleration of the cable during winding will affect the violent fluctuation of the tension, resulting in a large overshoot. Optimal control, at this time the tension change on the line ΔF x , dancing wheel angular acceleration α l The rise time t when the speed reaches a steady state c satisfy formula (1).

[0026] Δ F x R l = J l · α l = J l · V sd t c R l - - - ( 1 )

[0027] It can be seen that when the cable winding spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com