Beverage bottle stopper

A wine bottle stopper and beverage technology, applied in the field of wine bottle base, can solve the problems of certain sediment, loss of water, yellow-brown dry scab, etc., achieve high reuse rate, reduce bottle damage, and reduce bottle mouth loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

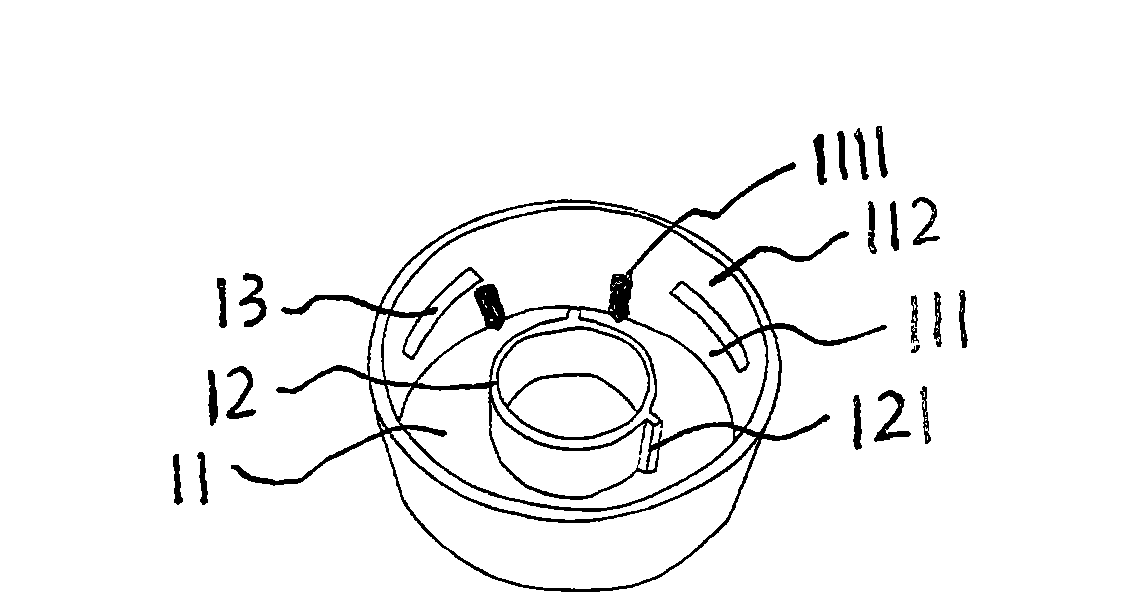

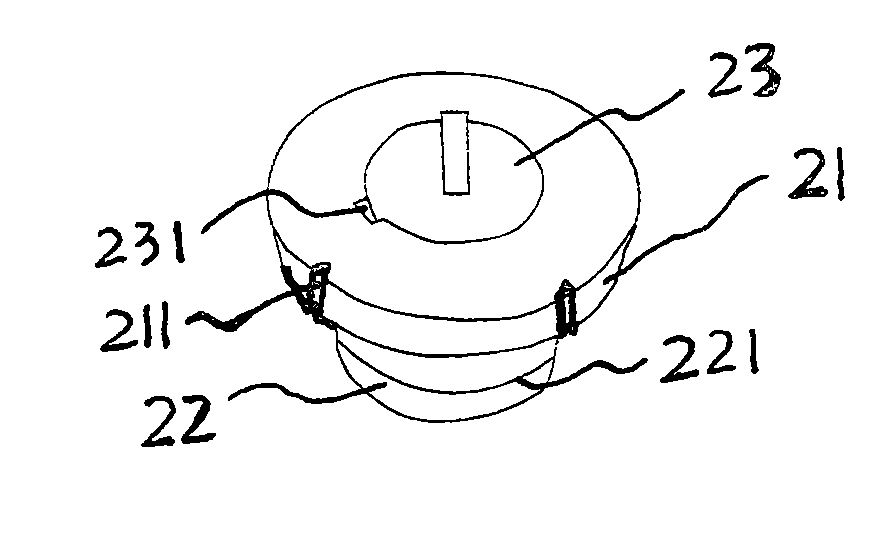

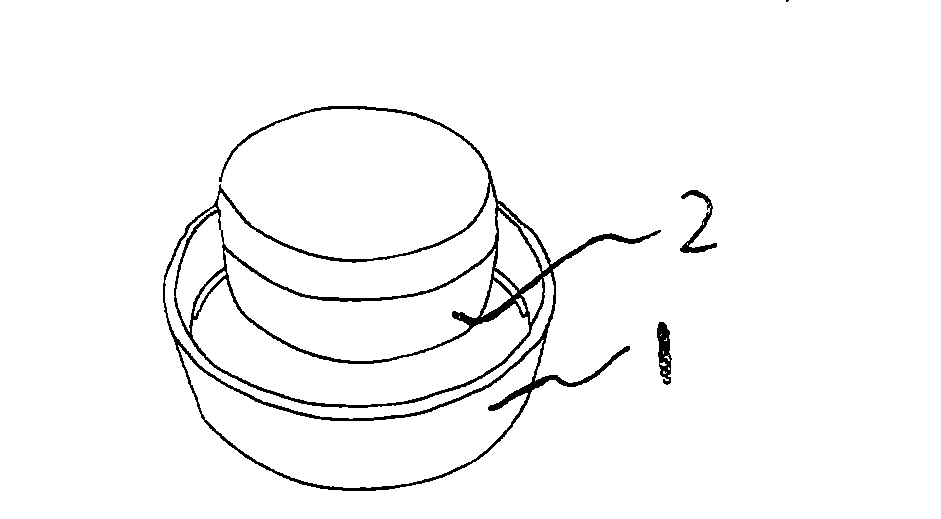

[0018] Such as Figure 1-3 As shown, a beverage bottle stopper including a cover body 1 and a plug body 2 is characterized in that: the cover body 1 is made of hard plastic material, the plug body 2 is made of soft silicone material; the upper part of the plug body 21 is inlaid In the cover body 1, the lower part of the plug body 22 can be pushed into the upper part of the bottle neck opening, and the lower part of the plug body body 22 and the bottle neck opening are tightly combined; its further feature is that the body of the cover body 1 is made of a cap suitable for accommodating the upper part of the plug body body 21 11 and the circular column 12 arranged in the central position of the cap 11; the plug body 2 is a "T" type plug body, and the upper part 21 of the plug body has a cavity 23 suitable for accommodating the circular column 12 at the central position in the cap, and A discontinuous snap ring 13 is arranged transversely at the near middle part of the inner side...

Embodiment 2

[0022] Such as Figure 1-3 As shown, its further feature is that several clamping rails 121 are equidistantly arranged on the outside of the circumference of the cover ring column 12, and correspondingly, on the inside of the circumference of the upper part of the "T"-shaped plug body cavity 23, etc. There are several locking grooves 231, which further ensure that the upper part of the plug body 21 is closely embedded with the cover body 1, and achieve the effect that the plug body 2 and the cover body 1 can rotate synchronously when the bottle cap is opened. All the other are with embodiment 1.

Embodiment 3

[0024] Such as Figure 1-3 As shown, its further feature is that several clamping rails 1111 are arranged longitudinally and equidistantly on the inner circumference of the upper half of the cap 111, and correspondingly, several longitudinally equidistantly arranged on the outer circumference of the upper part 21 of the "T" plug body. The bar clamping groove 211 further ensures that the upper part of the plug body 21 is tightly embedded with the cap body 1, and achieves the effect that the plug body 2 and the cap body 1 can rotate synchronously when the bottle cap is opened. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com