Packing machine with high-temperature stamping device

A packaging machine and high-temperature technology, which is applied in the field of silicone sealant packaging equipment, can solve the problems of time-consuming and labor-intensive use, and the large amount of silicone sealant used, and achieve the effects of saving labor intensity and power, saving processes, and reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

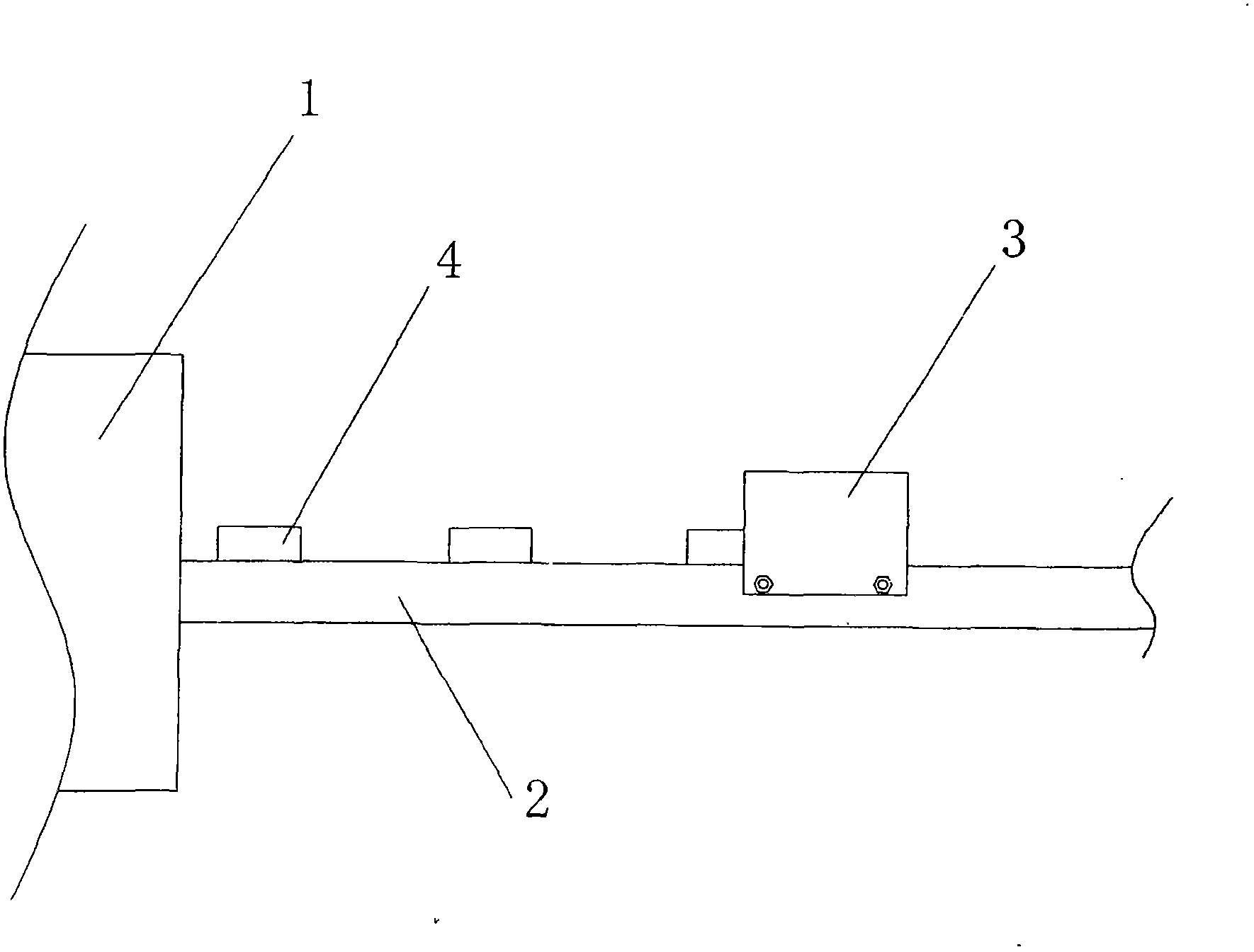

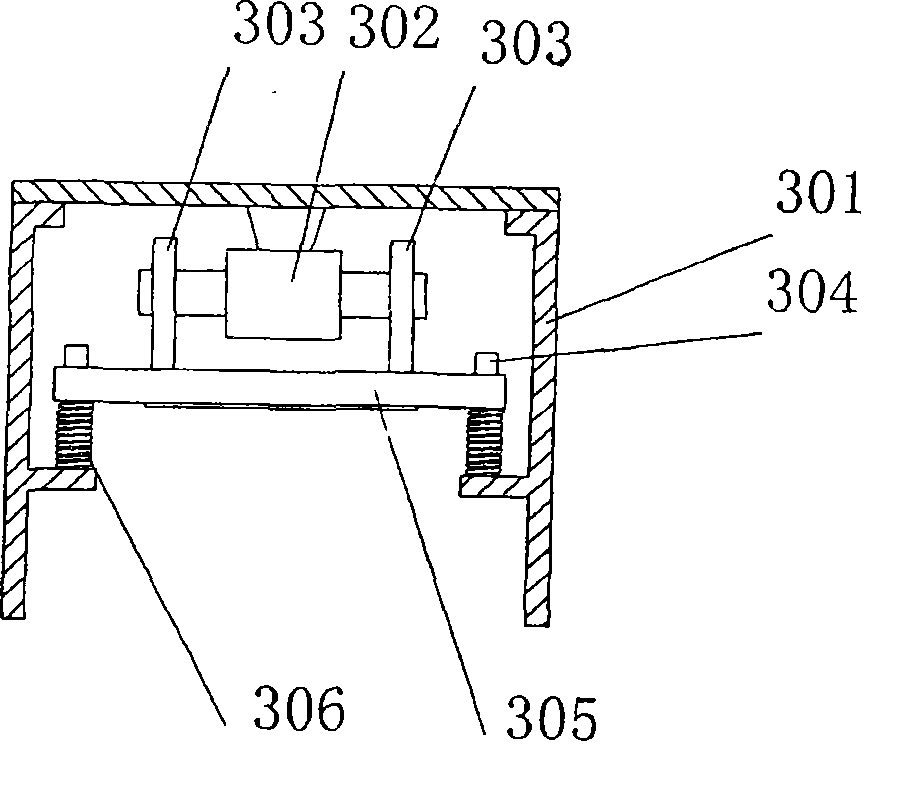

[0013] Example 1: Combining Figure 1-Figure 2 , a packaging machine with a high-temperature ironing device, including a packaging machine and a transmission device connected to the packaging machine, a high-temperature ironing device is provided on the transmission device, wherein the shells on both sides of the high-temperature ironing device pass through the fixing parts Connect to the transmission device. The distance between the lower working surface of the high-temperature ironing device and the upper working surface of the conveying device is greater than the thickness of the product. The high-temperature ironing device consists of a shell, and an inverted low-speed motor is fixedly installed on the top of the shell. Cams of equal size are connected to both ends of the rotating shaft of the low-speed motor. The ironing board is point heating, and guide holes are provided at the four top corners of the ironing board. The guide holes are matched with the guide shaft fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com