Bright surface printing method of uv inkjet printer with transparency and high color density

A printer and transparency technology, applied in printing and other directions, can solve the problems of poor pattern quality, high cost, and reducing the reflectivity and transparency of the reflective film of the processed parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

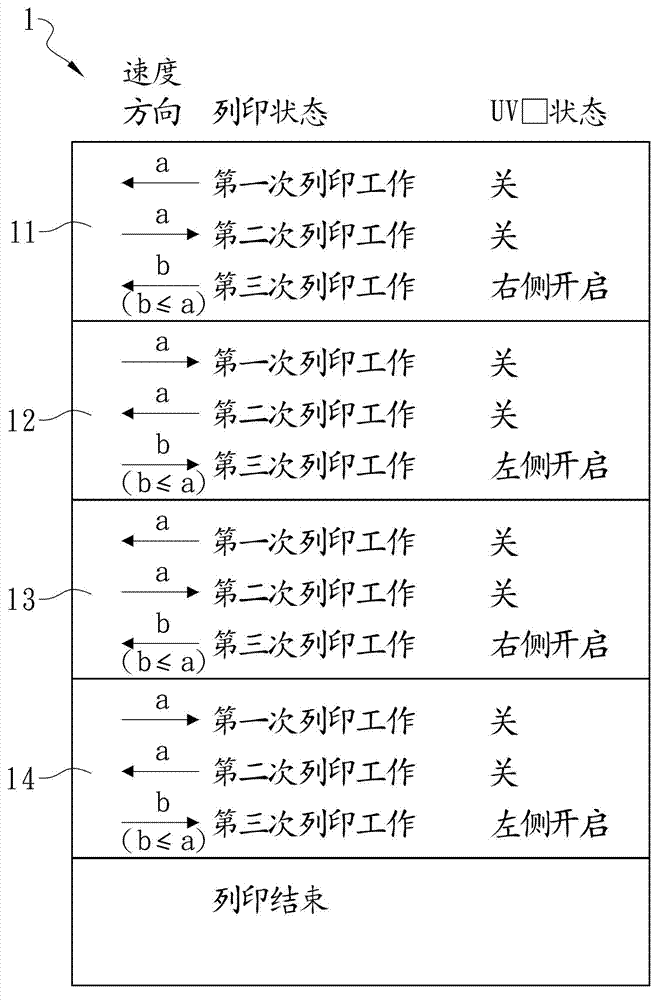

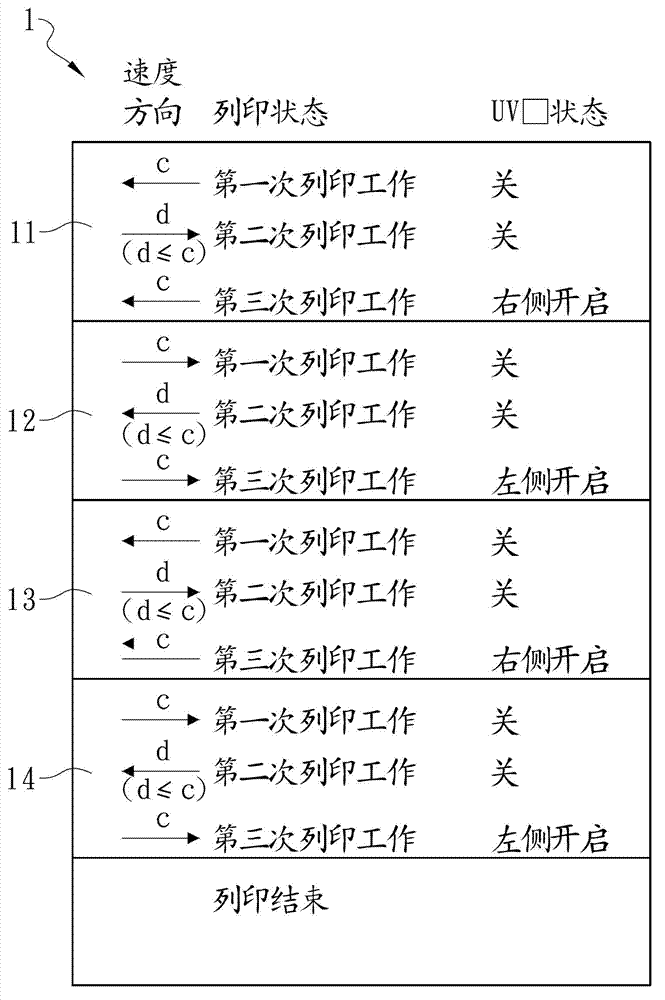

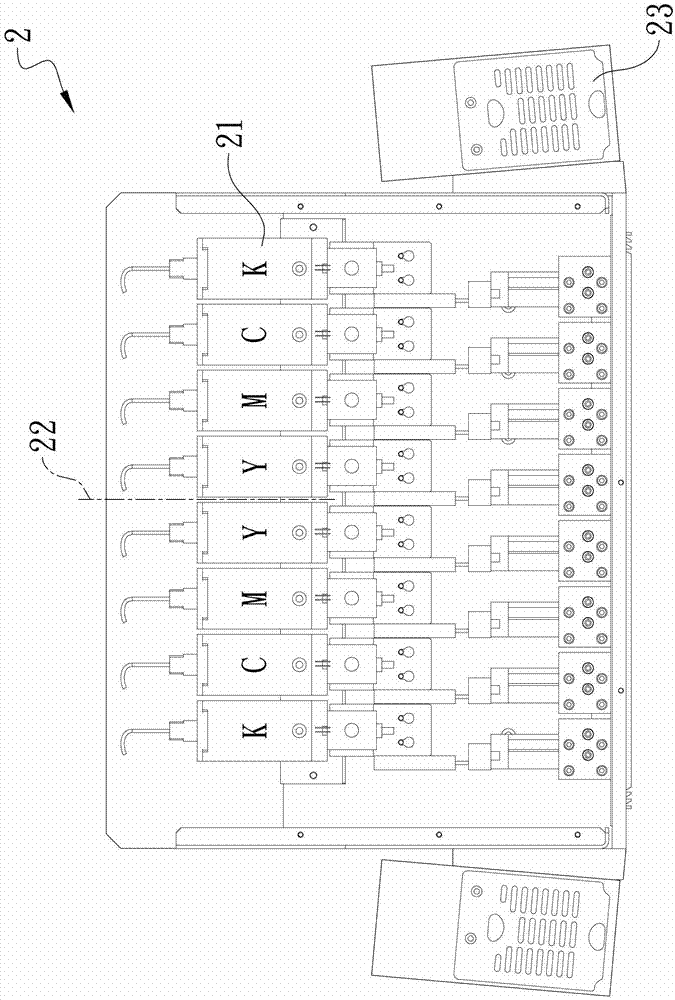

[0040] see Figure 1A , 1B , which is a schematic diagram of the operating structure of the first embodiment of the bright-side printing method of the UV inkjet printer with transparency and high color density in the present invention, wherein the inkjet module 2 of the UV inkjet printer is set There are several ink cartridges 21 (such as figure 2 As shown), the ink of each color is stored in two of the ink cartridges 21, and the two ink cartridges 21 are arranged symmetrically with respect to a center line 22 of the inkjet module 2, so that the ink cartridges 21 are black Arrangement order of (K)-cyan (C)-magenta (M)-yellow (Y)-yellow (Y)-magenta (M)-cyan (C)-black (K). Furthermore, two UV lamps 23 are respectively provided on both sides of the inkjet module 2 . This method is to execute the printing job in a back and forth manner, including the following steps:

[0041] (a) Divide a workpiece with a reflective film into several continuous printing areas according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com