VPF backplane for solar cell and processing process thereof

A solar cell and processing technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of easy aging of adhesives, accelerated PET decomposition, plasticization, etc., to improve overall performance, prolong service life, and overcome delamination. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

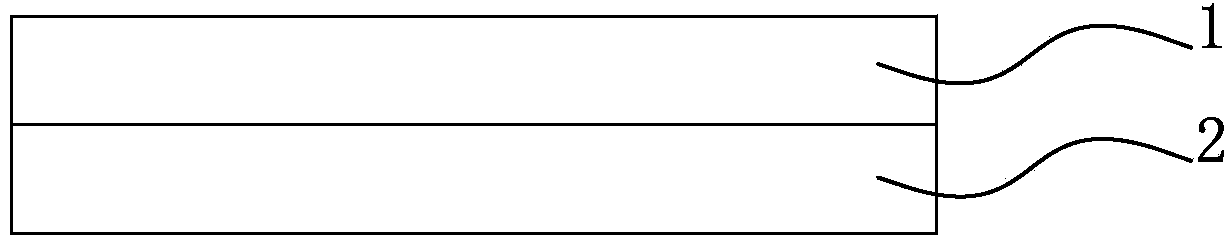

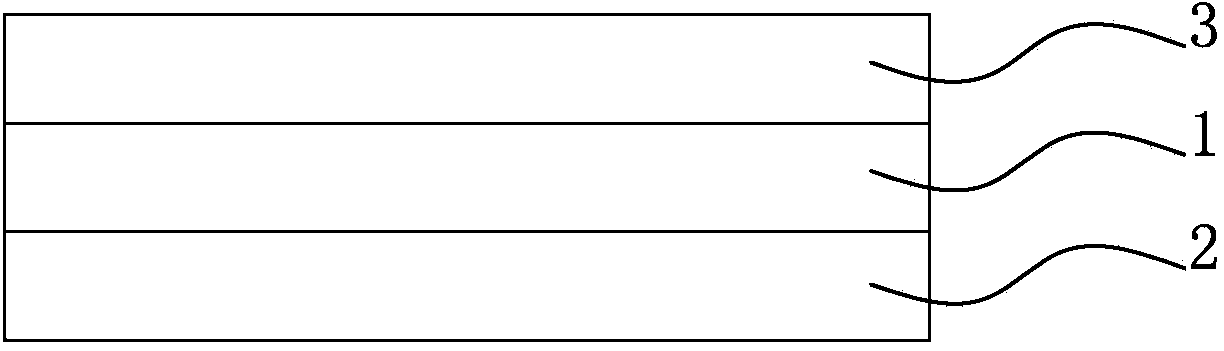

[0020] see figure 1 , an embodiment of a VPF back sheet for solar cells provided by the present invention, comprising a functional PET layer 1 and a conventional PET layer 2, the functional PET layer 1 and the conventional PET layer 2 are passed through a casting process Composite together. The conventional PET layer 2 in the present invention refers to a pure PET structure, which is the same as the existing mature products. The functional PET layer refers to a PET structure formed after blending and modification of conventional PET with anti-UV aging, heat and humidity resistance, and hydrolysis resistance. The functional PET layer contains an anti-ultraviolet aging agent and is resistant to ultraviolet and heat and humidity Aging performance. These modifiers can be completed by using mature products in the prior art. This functional PET layer is also a mature product, and the corresponding functional PET layer can be selected according to different performance requirements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com