Protection device of track of machine tool

A technology of protective devices and machine tools, which is used in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of moving to the guide rail, affecting the quality of the guide rail, and the guide rail is not provided with a protective cover, etc., to achieve smooth movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

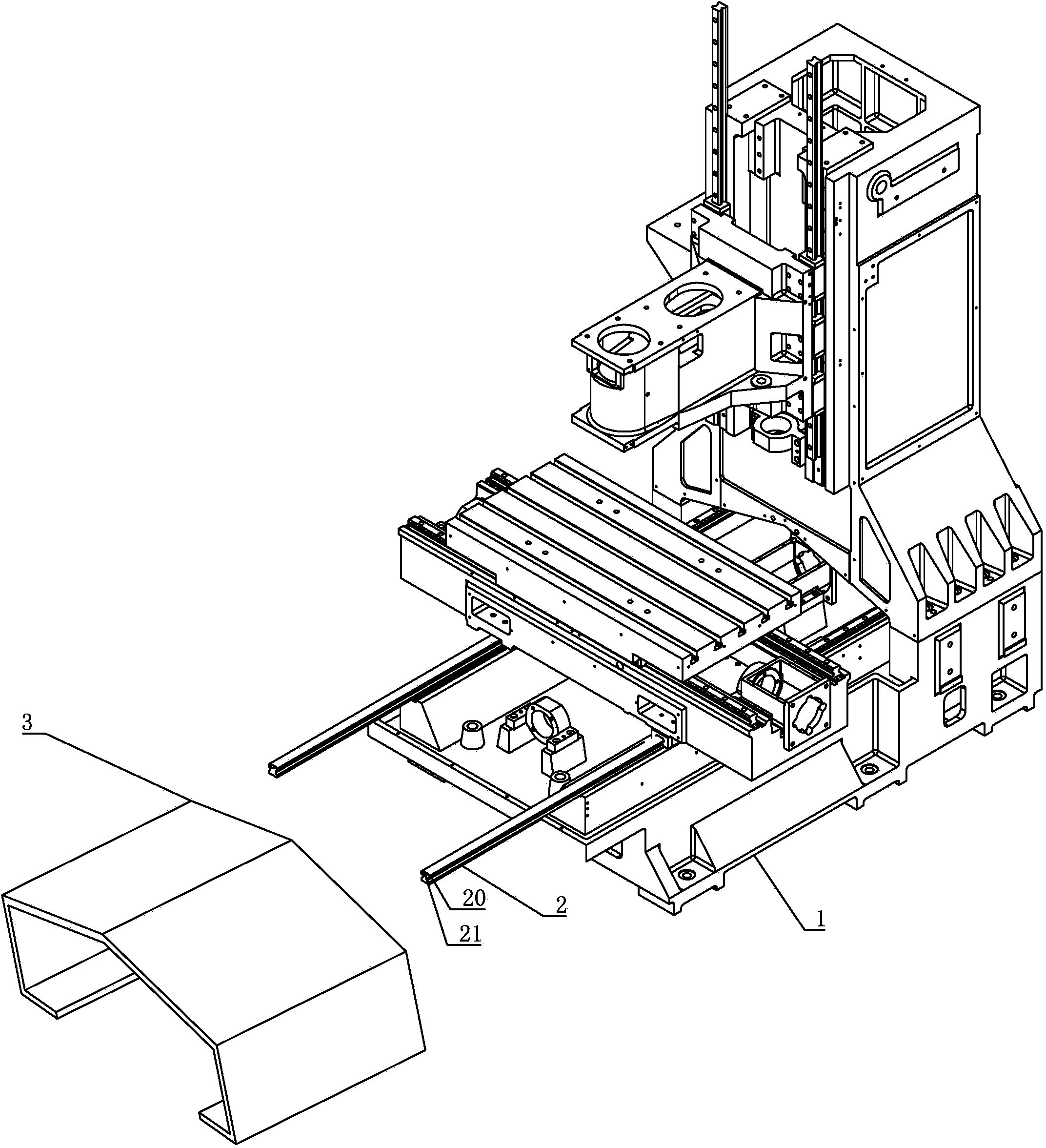

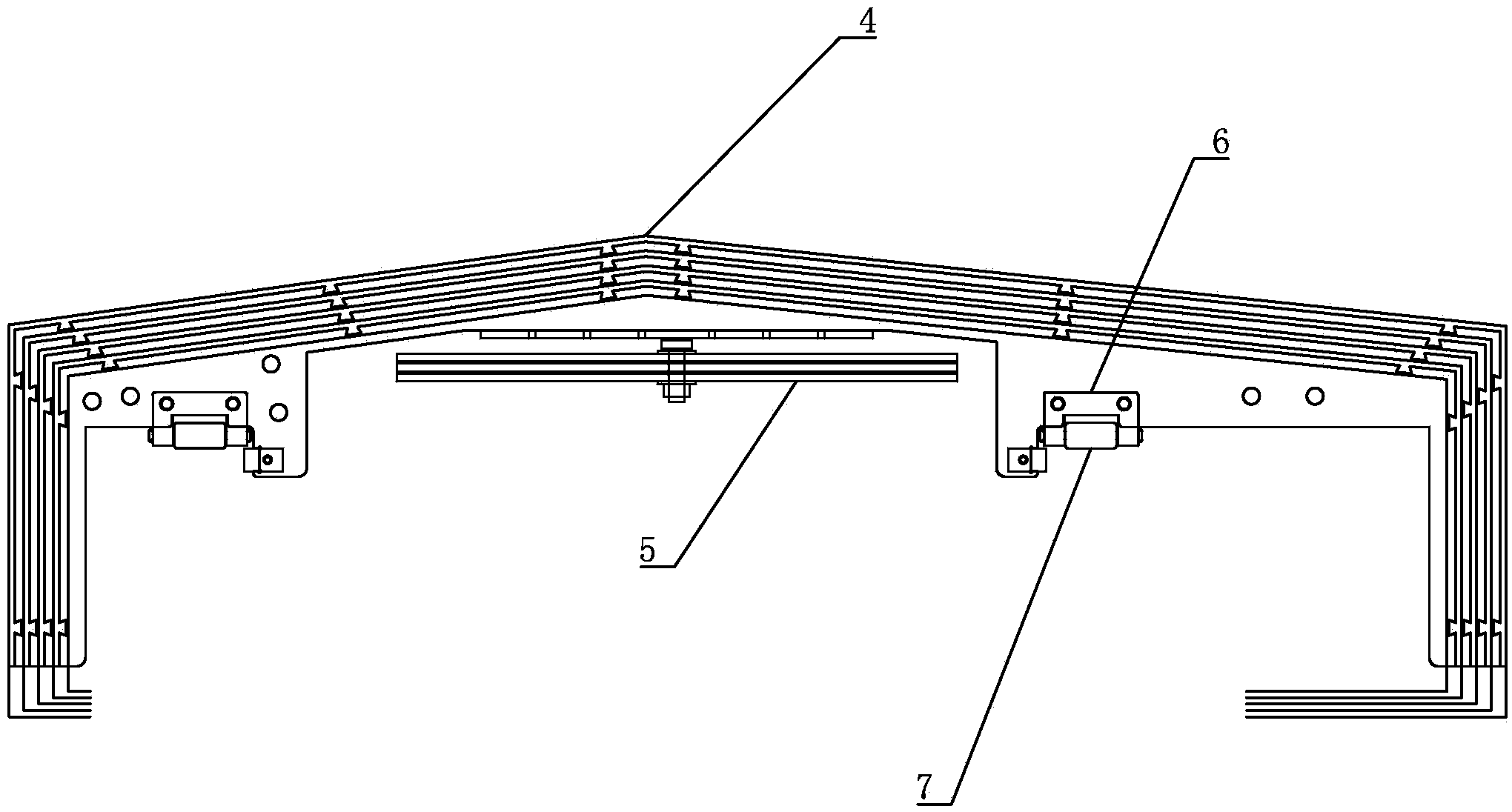

[0011] Such as Figure 1~Figure 2 As shown, a protective device for the track of a machine tool includes a guide rail 2 protruding from a machine tool base 1, a hollow protective plate 20 is arranged on the guide rail 2, the lower end of the protective plate 20 is open, and the protective plate 20 The closed end covers the top surface of the guide rail 2, and the left and right sides of the protective plate 20 are respectively close to the left and right sides of the guide rail 2. The length of the protective plate 20 is consistent with that of the guide rail 2, and the front and rear ends of the protective plate 20 are respectively downward. Bending to form a positioning part 21, the part of the guide rail 2 protruding from the base is equipped with a protective cover 3, the protective cover 3 includes a hollow cover body 4, and the cover body 4 includes five stacked ones that can slide relative to each other. The sliding cover, preferably, the sliding cover is made of stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com