Side supporting device of working roll of cold rolling machine

A technology of side support and work roll, applied in the direction of back pressure device, metal rolling, metal rolling, etc., can solve the problems of complex processing of rack and roll system, small rolling mill space, low unit output, etc. and surface quality, stable rolling process, and the effect of maintaining the rolling state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and embodiments.

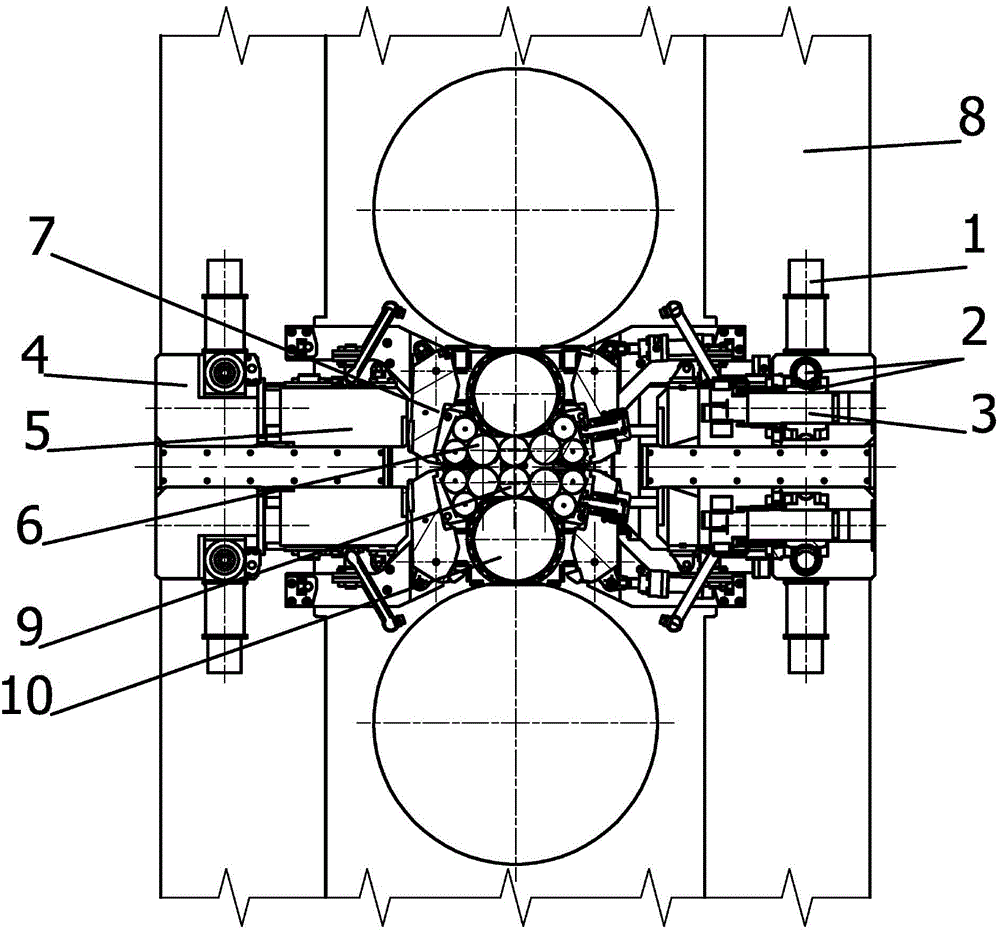

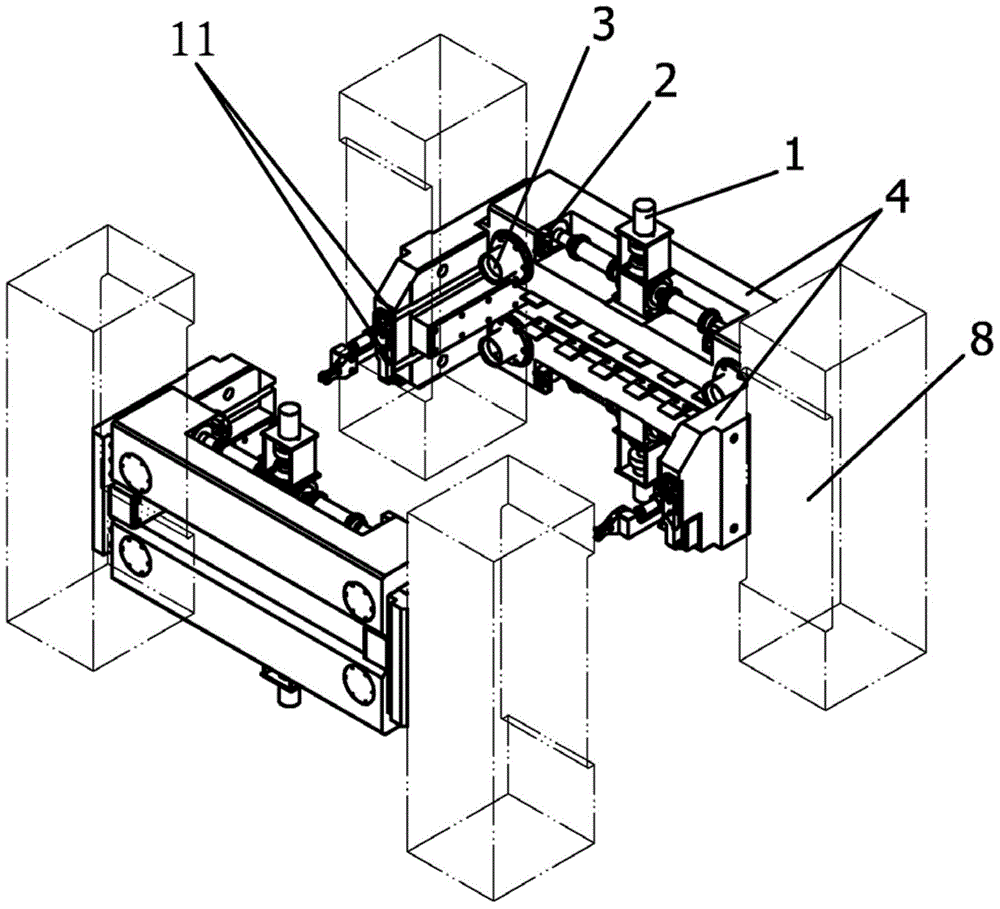

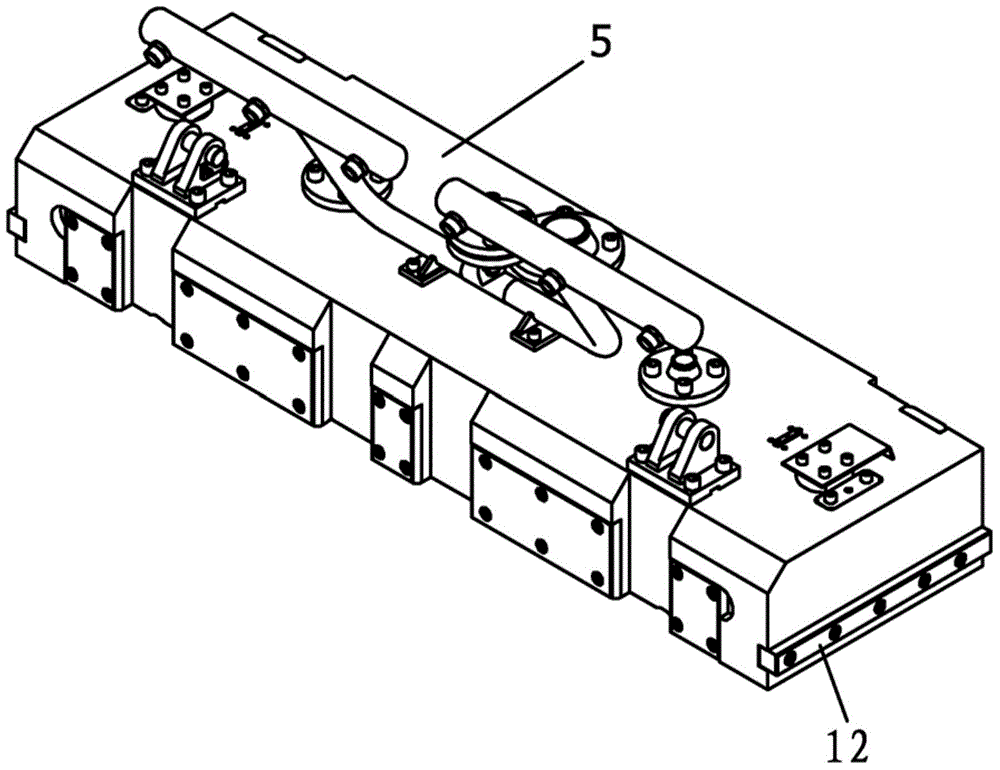

[0017] The specific embodiment of the present invention is shown in the drawings. The device includes a fixing device 4, a moving device 5, a side support roller swing lever device 7 and a side support roller system 6. The fixing device 4 includes a channel steel frame, an oil motor 1, a worm gear For mechanism 2 and screw mechanism 3, two transverse slide grooves 11 are arranged in the middle of the two wall plates of the channel steel frame. Two oil motors 1 are installed on the bottom plate of the channel steel frame, respectively located in the middle of the two sides of the bottom plate. The worm gear mechanism 2 is installed on the bottom plate of the channel steel frame, respectively located at the four corners of the bottom plate. The input ends of the two worm gear mechanisms 2 mounted on the channel steel frame bottom plate and the oil installed in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com