Charged sweeper

A live cleaning and insulated rotating shaft technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of not easy to control and use, and inconvenient operation, etc., to achieve convenient and easy control of the cleaning process , labor-saving operation and long charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

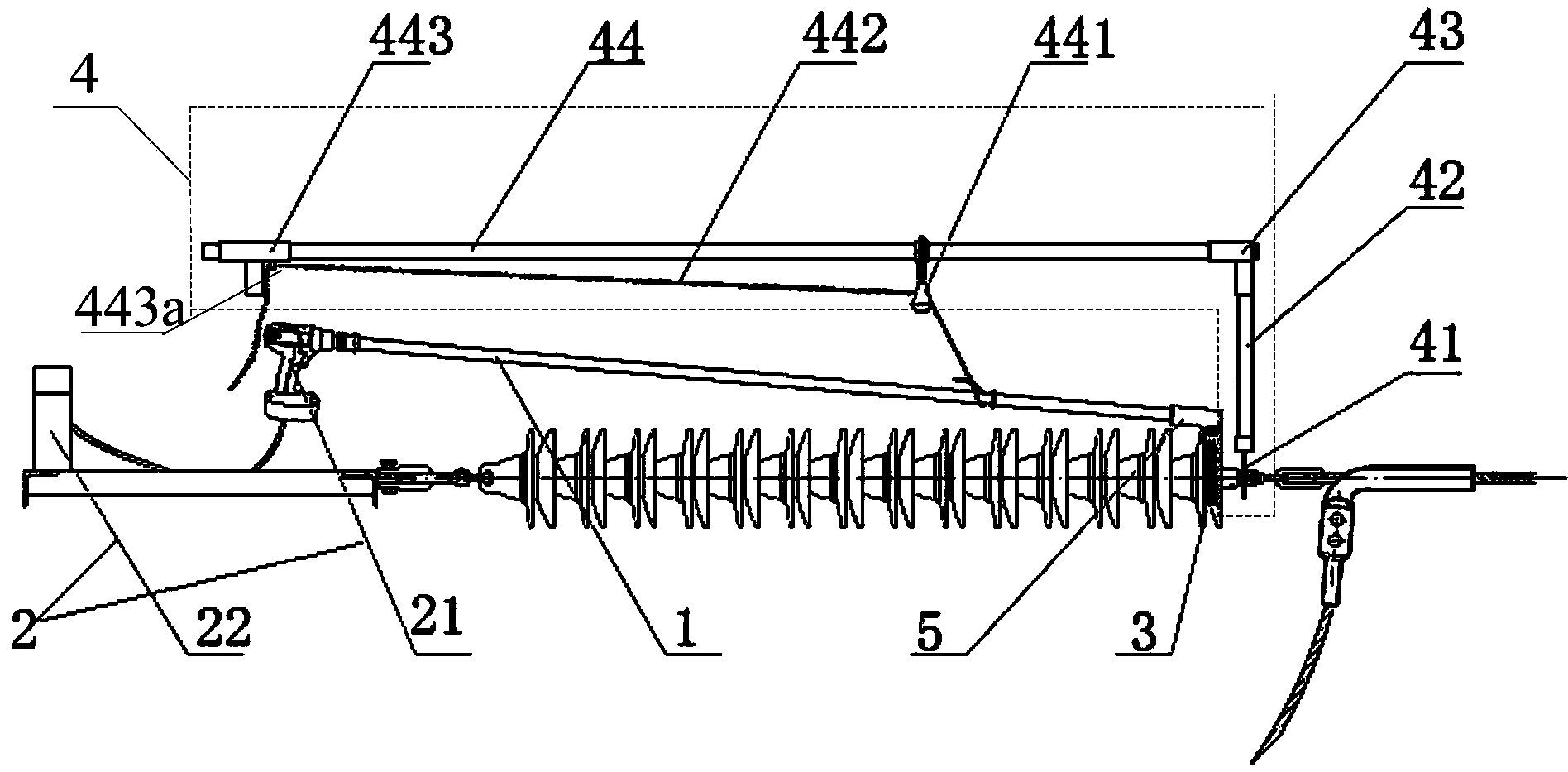

[0030] This embodiment provides a live cleaner, such as figure 1 As shown, it includes a main insulating transmission rod 1, which is provided with an insulating rotating shaft. One end of the insulating rotating shaft is connected to the power source 2, and the other end is connected to the brush body 3. The output power of the power source 2 drives the insulating rotating shaft to rotate and then drives the Described brush body 3 rotates. The live cleaner described in this embodiment also includes:

[0031] The positioning device 4 is used to fix the charged cleaner on the cleaning object.

[0032] The positioning device 4 includes:

[0033] One end of the positioning fork 41 is used to be fixed on the cleaning object, and the other end is connected to one end of the first insulating support rod 42 .

[0034] The other end of the first insulating support rod 42 is connected to one end of the second insulating support rod 44 through a bend 43 .

[0035] The pulley 441 is ...

Embodiment 2

[0041]On the basis of Embodiment 1, the live cleaner described in this embodiment, such as figure 1 As shown, the other end of the second insulating support rod 44 is provided with a handle 443 .

[0042] The positioning ring 443a is fixed on the handle 443 .

[0043] The insulating rope 442 passes through the pulley 441 and passes through the positioning ring 443a.

[0044] The live cleaner described in this embodiment, by adding a handle 443 with a positioning ring 443a on the second insulating rod, can facilitate the operator to manipulate the insulating rope 442 and facilitate the operator to adjust the cleaning position of the brush body 3 .

[0045] As a preferred implementation, the charged cleaner described in this embodiment, the power source 2, includes:

[0046] A handheld DC motor 21 and a lithium battery 22 are electrically connected between the handheld DC motor 21 and the lithium battery 22; the output shaft of the handheld DC motor 21 is connected to one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com