A filter housing multi-station glue injection machine

A multi-station and filter technology, applied in the field of glue injection machines, can solve the problems of low production efficiency, low qualified rate of finished products, manual gluing of filters, etc., and achieves convenient operation, simple structure, and improved glue injection. The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

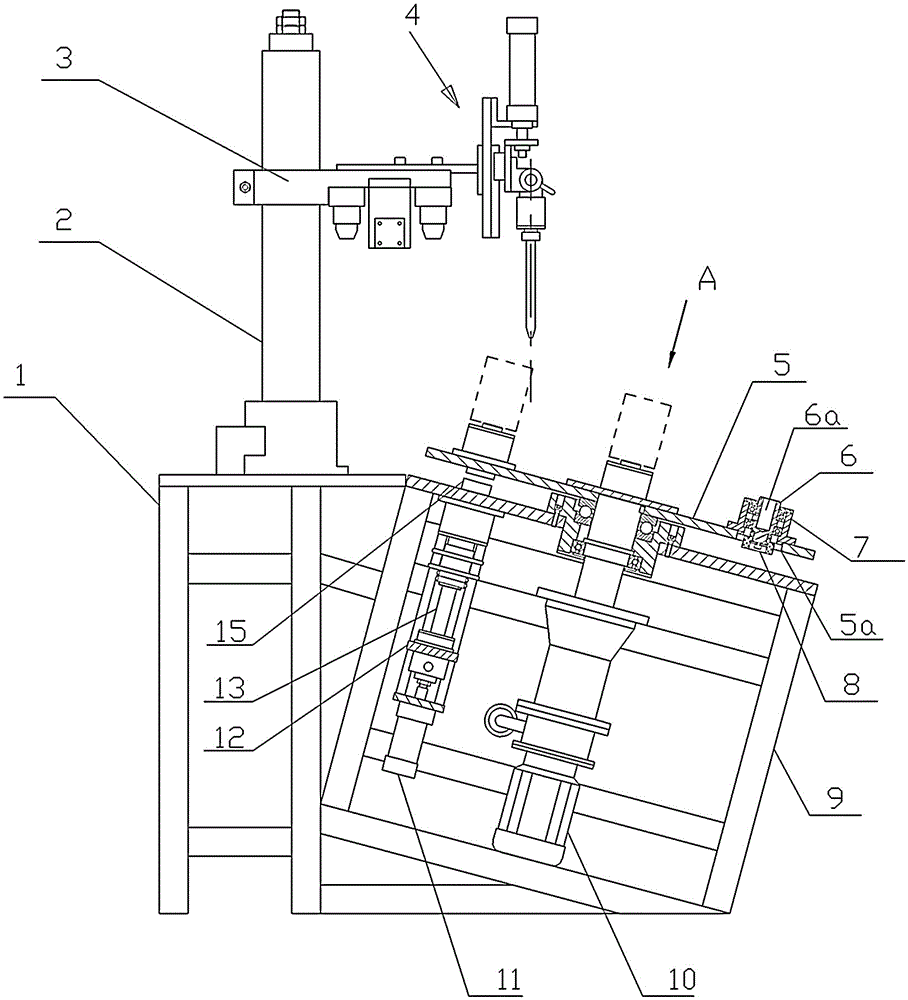

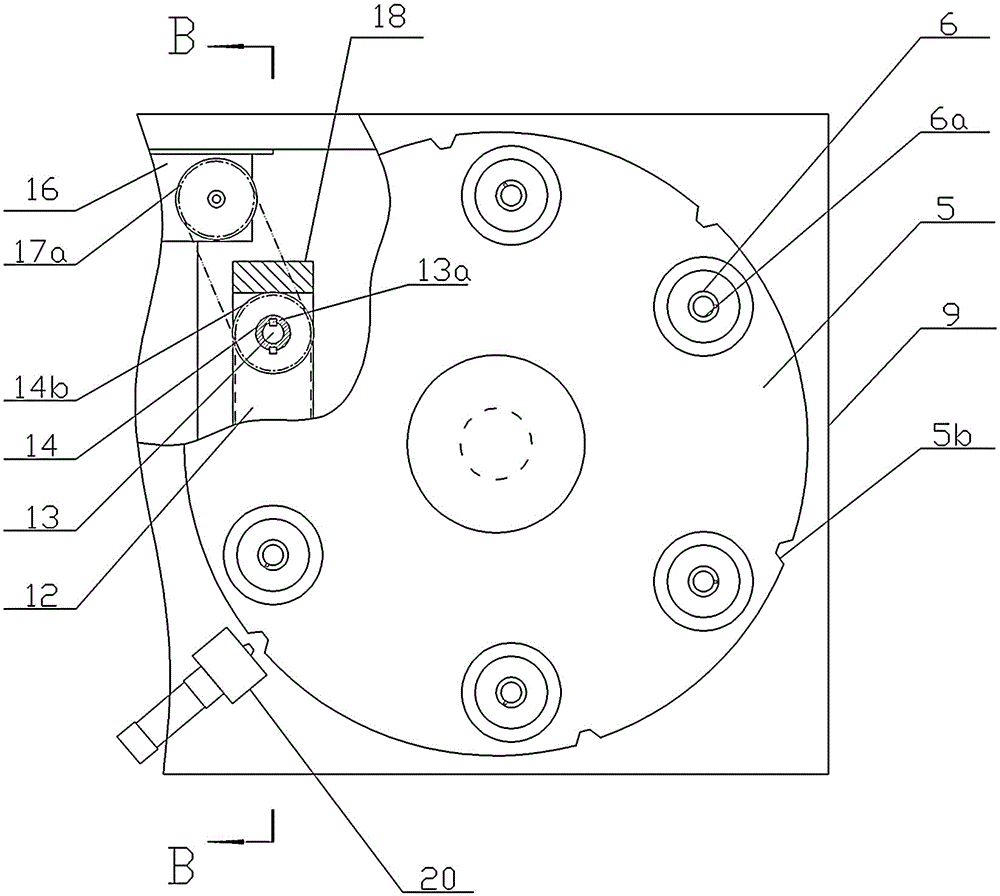

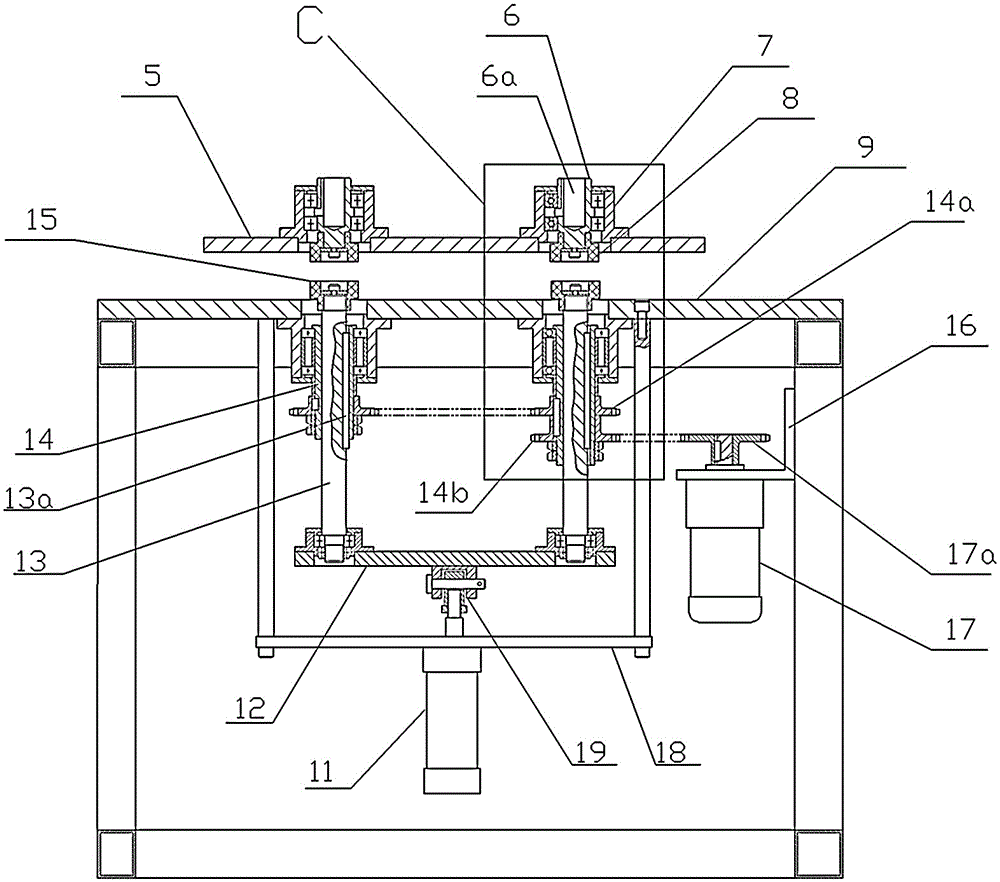

[0018] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a filter shell multi-station glue injection machine provided for the invention includes a main workbench 1, a column 2 is arranged on the main workbench, a rocker arm 3 is arranged on the pillar, and one end of the rocker arm is connected with a glue injection Device 4, an auxiliary workbench 9 is provided on one side of the main workbench 1 directly below the glue injection device. There is a first motor 10 in the platform, the driving shaft of the first motor passes through the sub-table surface, and is connected with the rotary disk 5, and a group of circumferentially distributed through holes 5a are evenly distributed on the rotary disk, and the position of each through hole is The rotary discs are provided with fixture bearing seats 7, and the fixture bearing seats are provided with a fixture rotating shaft 6 for clamping the filter housing. The upper end of the fixture rotating shaft is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com