Low-pressure chamber connection throat structure

A low-pressure chamber and throat technology, which is applied in the field of low-pressure chamber connecting throat structures, can solve the problems of time uncertainty, unstable blasting time, and difficulty in measuring and controlling blasting time, and achieves the effects of fast startup, simple structure, and reliable sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

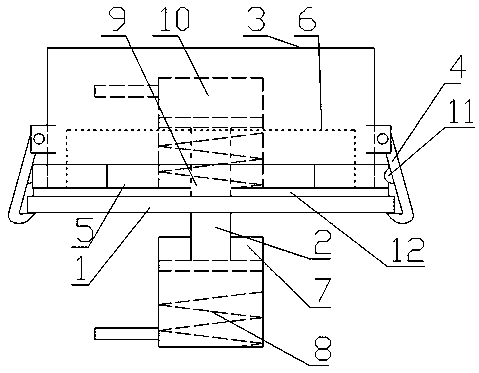

[0012] Embodiments of the invention. The low pressure chamber is connected to the throat structure, such as figure 1 As shown, the door assembly 1 is made, the cylinder rod 2 is connected to the bottom of the door assembly 1, the cylinder rod 2 is connected to the oil cylinder assembly 7, and the airtight door frame 3 is installed above the door assembly 1, and the airtight door frame 3 is installed on the side for the door assembly 1, the fixed hook 4 is provided with a protruding power ring 5 inside the fixed hook 4, and the power ring 5 is connected to the pneumatic rotary motor 6.

[0013] A buffer spring 8 is installed in the oil cylinder assembly 7 to reduce the impact force of the hatch assembly 1 and the oil cylinder rod 2 .

[0014] A reset oil cylinder rod 9 is installed above the hatch assembly 1, and the reset oil cylinder rod 9 is connected to the reset oil cylinder assembly 10. A buffer spring 8 is also installed in the reset oil cylinder assembly 10 .

[0015...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com