Feather removal machine used in duck feather removal streamline

An assembly line and hair removal machine technology, applied in the field of hair removal machines, can solve the problems of inconvenient maintenance and operation, inability to meet the needs of modern civilized production, and low degree of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

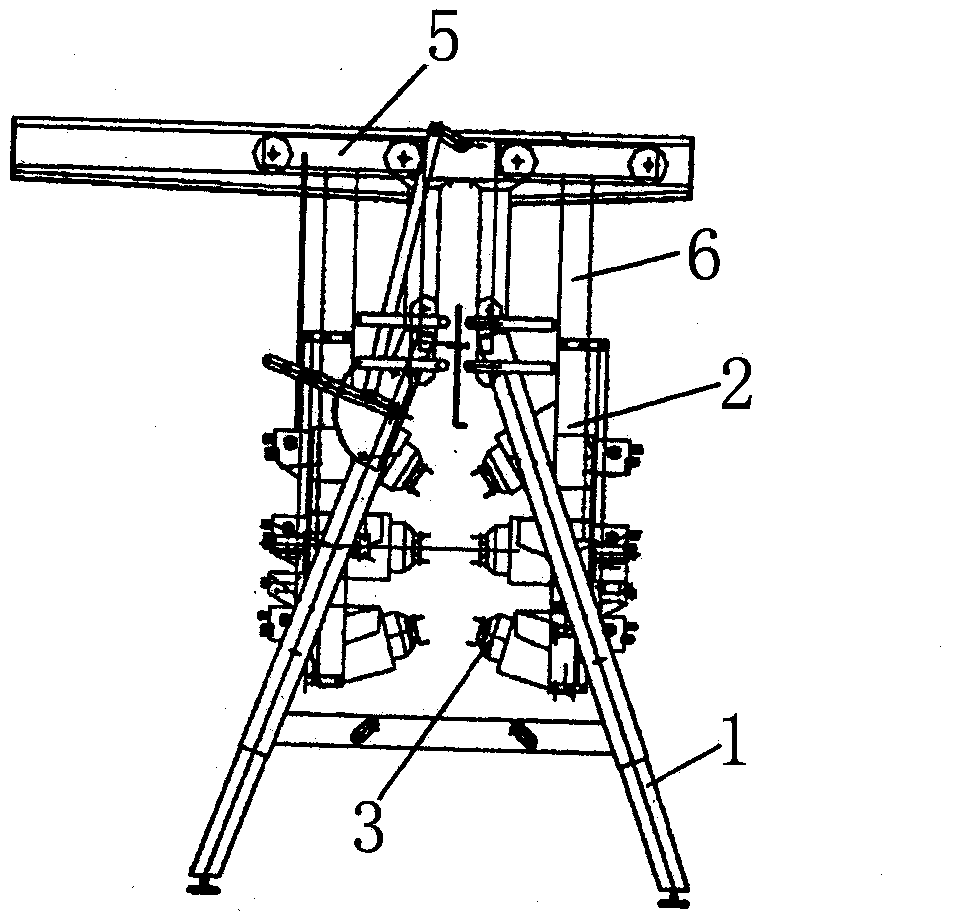

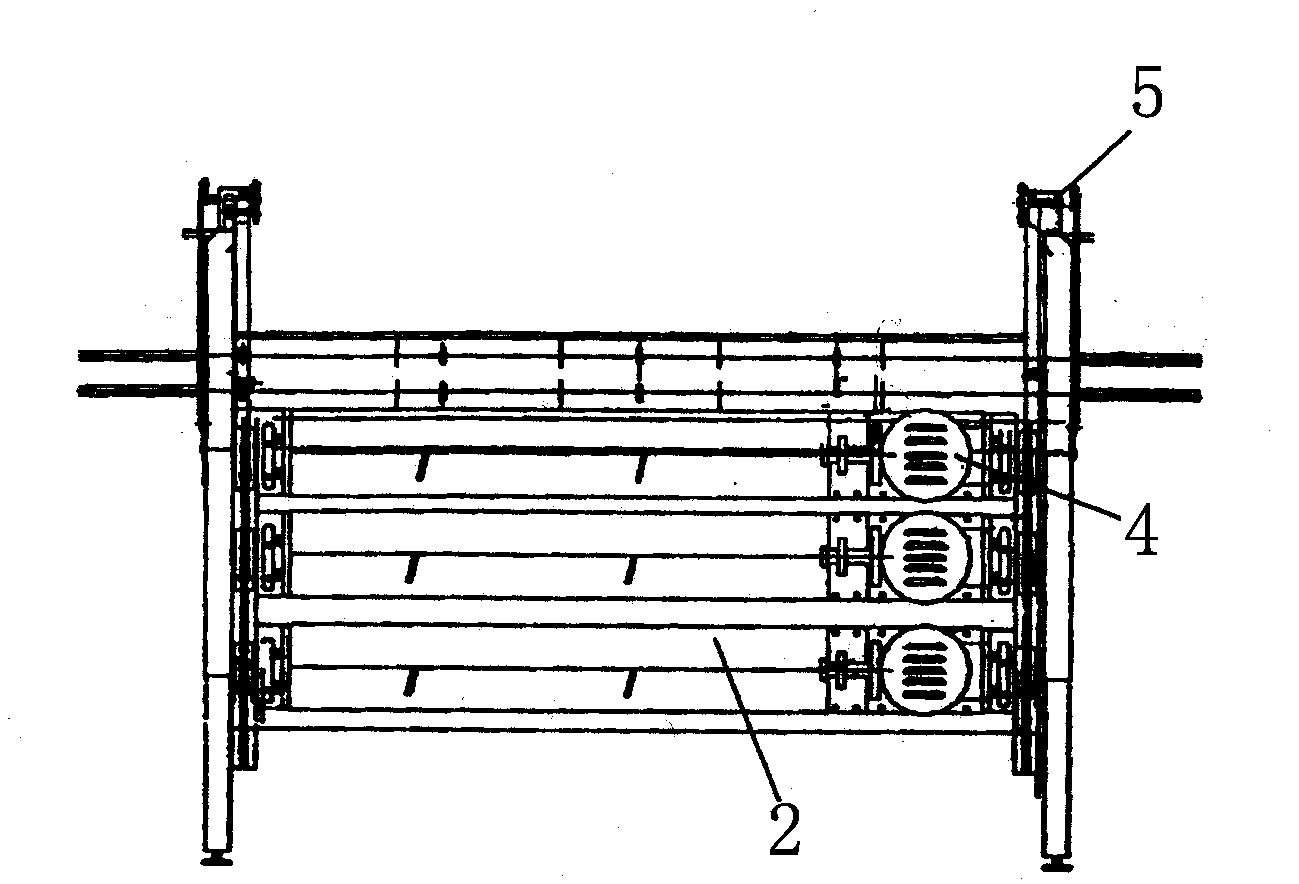

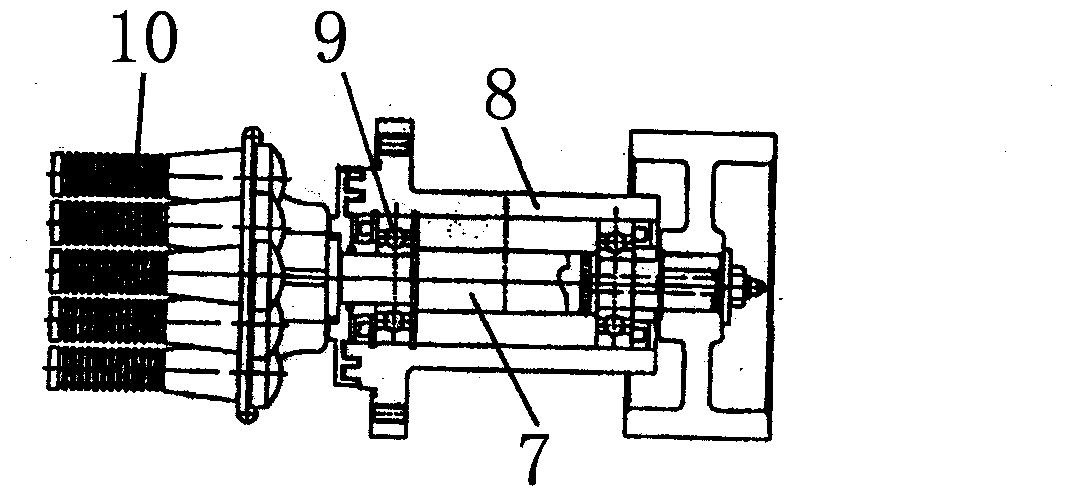

[0011] Such as figure 1 , 2 , 3, the present invention is respectively horizontally provided with three groups of cabinets 2 on both sides of the A-shaped frame 1, and multiple groups of depilatory disks 3 are horizontally arranged in the cabinet 2, and each group of depilatory disks 3 is driven by a motor 4, and the suspension arm 5 The upper end of the A-shaped frame 1 and the cabinet 2 are suspended by the boom 6, which can slide left and right on the suspension arm 5. The shaft roller 7 of the depilation disk 3 is supported in the shaft sleeve 9 by a bearing 8, and a plurality of hair removal rods 10 are arranged at one end of the shaft roller 7. Through the above arrangement, the poultry body enters between the two cabinets 2 of the present invention on the assembly line, and the motor 4 drives the depilation disk 3 to rotate, and the friction between the depilation rod 10 and the poultry body realizes the depilation of the poultry body. By adjusting the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com