Hybrid absorption-compression chiller

A hybrid and compression refrigeration technology, which is applied in the direction of compressors, independent rotary compressors, refrigerators, etc., can solve the problems of complex absorption-compression refrigerators and inoperability of evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

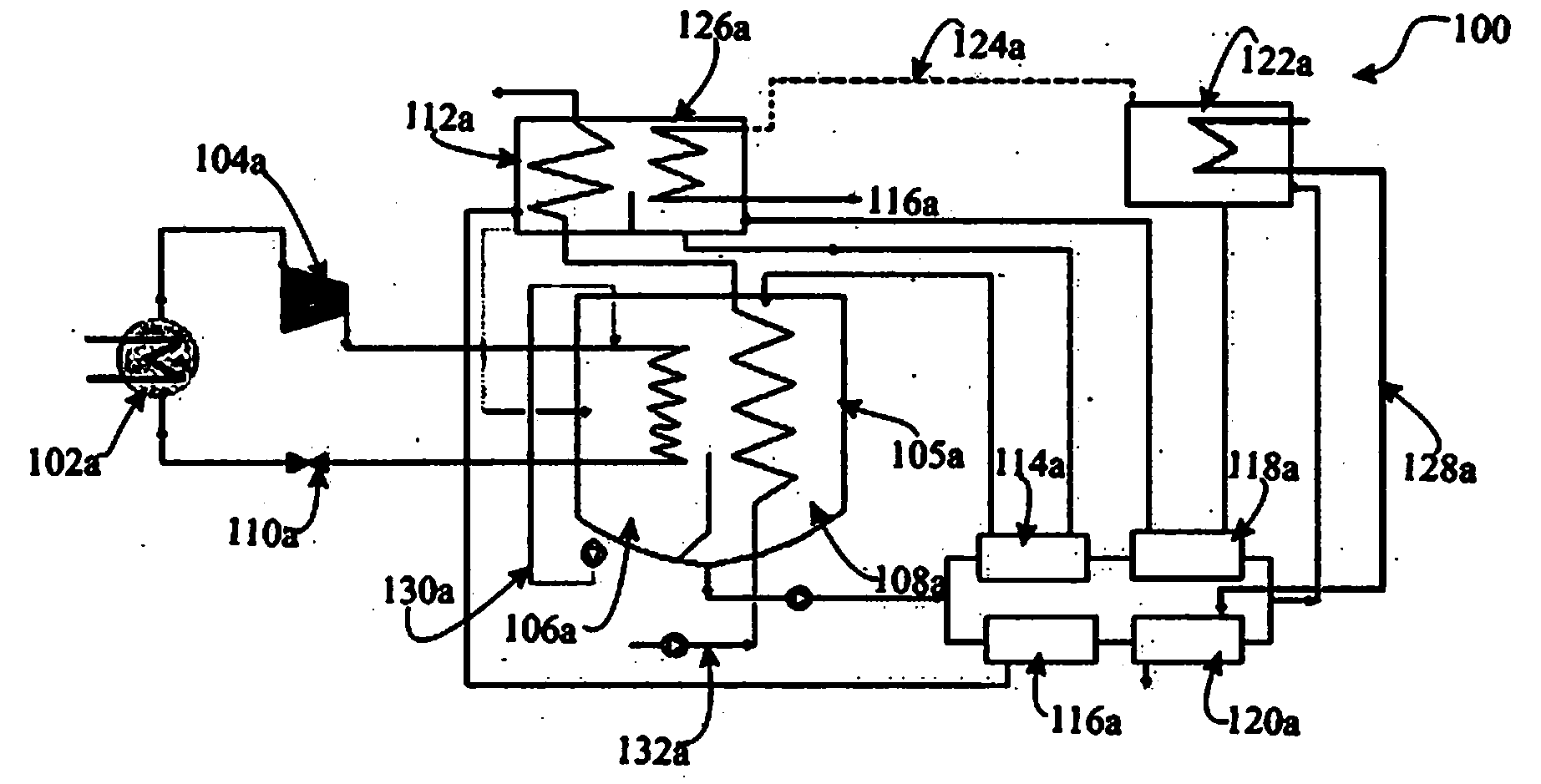

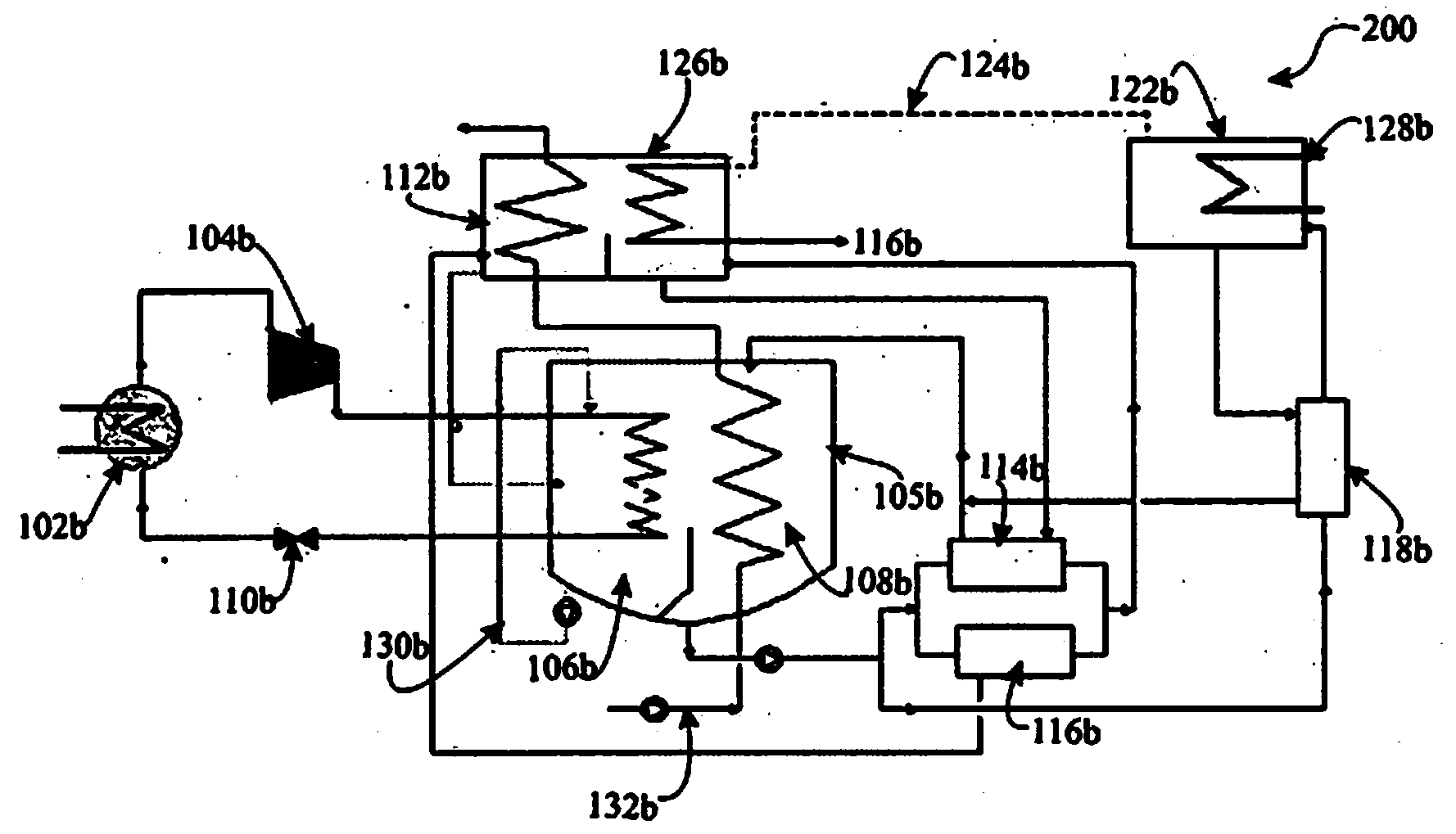

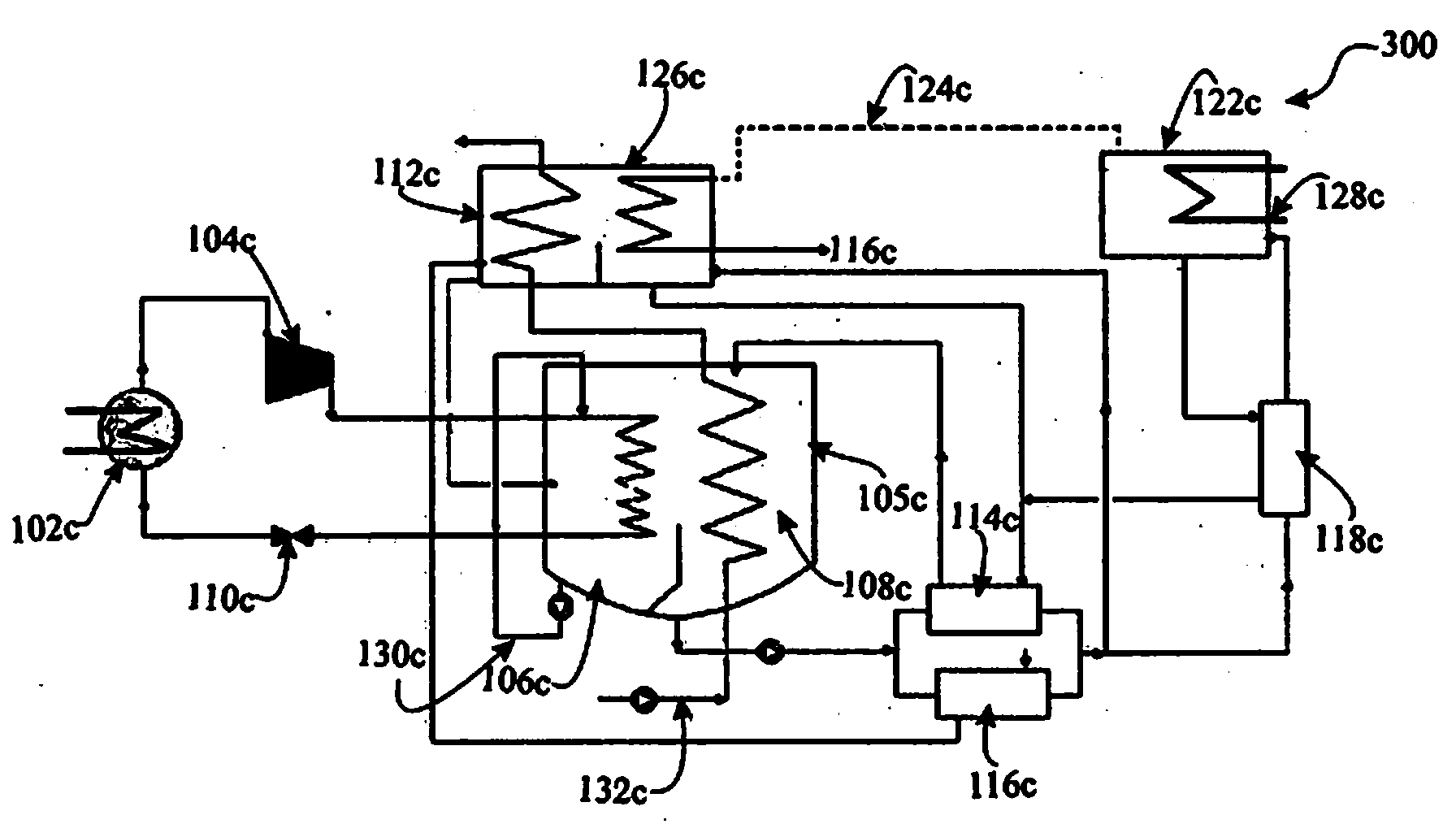

[0047] Now, the invention is described based on the accompanying drawings, which do not limit the scope and bounds of the invention. The description is provided entirely by way of example and illustration.

[0048] The present invention contemplates a hybrid absorption-compression refrigerator that includes a vapor compression system that provides refrigeration in a primary evaporator by absorbing heat from the object to be cooled by condensing a primary coolant, where the condensing primary The coolant is usually selected from tetrafluoroethane (R134a), dichlorotrifluoroethane (R123), trifluoroethane (R143a) and carbon dioxide (R744); also contains a vapor absorption system which is compatible with Vapor compression systems are operatively communicated through compressors to receive primary coolant vapors, which are cooled by condensed secondary coolant, typified by water, to provide condensed primary coolant that will be circulated to the vapor compression system. The prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com